Preparation method of fluorosilicone modified carbamido compound

A technology of fluorine-silicon modification and compound, which is applied in the field of preparation of urea-based compounds, can solve the problems of excessive leveling agent selection, increase the amount of leveling agent, and poor water solubility of coatings, so as to avoid crystallization and increase dissolution properties, low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

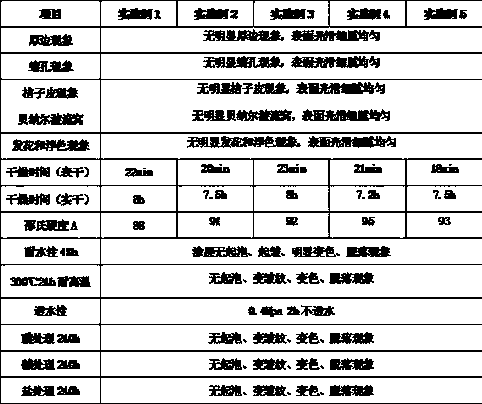

Examples

preparation example Construction

[0033] The invention discloses a preparation method of a fluorine-silicon modified ureido compound, which comprises the following steps:

[0034] (1) Synthesis of fluorosilicone adducts: add γ-aminopropyltrialkoxysilane into the reaction kettle and pass nitrogen gas for 8-10 minutes, then raise the temperature to 30-60°C, start stirring and maintain the stirring speed 500-900r / min, add the ternary mixture of hexafluoropropylene dimer, hexafluoropropylene trimer and dialkyl maleate dropwise into the reaction kettle, and keep the exothermic temperature of the reaction after the dropwise addition Continue to react for 12-24h to obtain fluorosilicone adduct;

[0035] (2) Preparation of fluorine-silicon modified urea-based compounds: Cool the above-mentioned fluorosilicone adduct to below 30°C, continue stirring at 500-900r / min, and add isocyanate monomer or isocyanate prepolymer dropwise , add dropwise according to the NH / NCO molar ratio of 1:1, the drop rate is 1-2 drops / S, the ...

Embodiment 1

[0047] The invention discloses a preparation method of a fluorine-silicon modified ureido compound, which comprises the following steps:

[0048] (1) Synthesis of fluorosiloxane adducts: add γ-aminopropyltrialkoxysilane into the reaction kettle and pass nitrogen gas for 10 minutes, then raise the temperature to 45°C, start stirring and maintain the stirring speed at 500r / min , add the ternary mixture of hexafluoropropylene dimer, hexafluoropropylene trimer and dialkyl maleate dropwise into the reaction kettle, keep the exothermic temperature of the reaction and continue the reaction for 24h after the dropwise addition, to obtain fluorine Siloxane adducts;

[0049] (2) Preparation of fluorine-silicon modified urea-based compounds: Cool the above-mentioned fluorosiloxane adduct to below 30°C, continue stirring at 700r / min, add isocyanate monomer or isocyanate prepolymer dropwise, press NH / NCO molar ratio of 1:1 is added dropwise, the drop rate is 1-2 drops / S, the dropwise addit...

Embodiment 2

[0054] The invention discloses a preparation method of a fluorine-silicon modified ureido compound, which comprises the following steps:

[0055] (1) Synthesis of fluorosiloxane adducts: add γ-aminopropyltrialkoxysilane into the reaction kettle and pass nitrogen gas for 9 minutes, then raise the temperature to 30°C, start stirring and maintain the stirring speed at 900r / min , add the ternary mixture of hexafluoropropylene dimer, hexafluoropropylene trimer and dialkyl maleate dropwise into the reaction kettle, keep the exothermic temperature of the reaction and continue the reaction for 18h after the dropwise addition, to obtain fluorine Siloxane adducts;

[0056] (2) Preparation of fluorine-silicon modified urea-based compounds: Cool the above-mentioned fluorosiloxane adduct to below 30°C, continue stirring at 500r / min, add isocyanate monomer or isocyanate prepolymer dropwise, press NH / NCO molar ratio of 1:1 is added dropwise, the drop rate is 1-2 drops / S, the dropwise additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com