Method for preparing nonpolar polyvinylidene fluoride ultrafiltration membrane

A polyvinylidene fluoride and ultrafiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of less interference, stable film-forming performance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

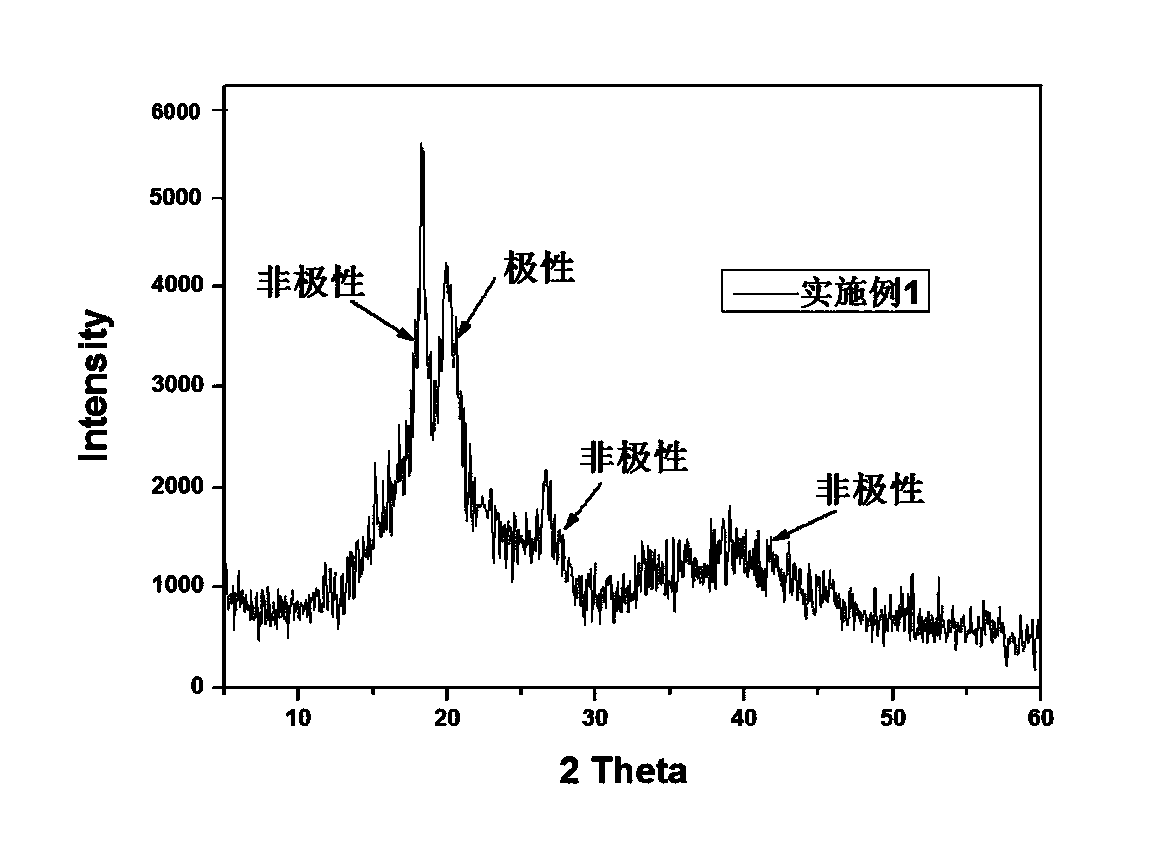

Embodiment 1

[0033] PVDF (viscosity average molecular weight M v =345,000g / mol, the smaller molecular weight can accelerate the stable formation of the crystal form) and ethanol are dissolved in a mixture of dimethylacetamide (DMAC) and acetone at 60°C, and the mass percentage of raw materials is PVDF: DMAC : Acetone: Ethanol = 12: 24: 62: 2, stir until PVDF is completely dissolved, let it stand for defoaming, scrape it on a clean and flat glass plate with a scraper, and expose it to air for 2 hours (volatile solvent is good for non-polar conformation Formation). Immerse the scraped film solution in the first gel bath for 10 minutes, the temperature of the first gel bath is 40°C, and the high temperature accelerates the formation of α crystal form, the composition of the first gel bath is: the mass percentage concentration is 50% octane Aqueous solution of alcohol to get nascent film. The nascent membrane was then immersed in a second gel bath containing only deionized water at 40°C for ...

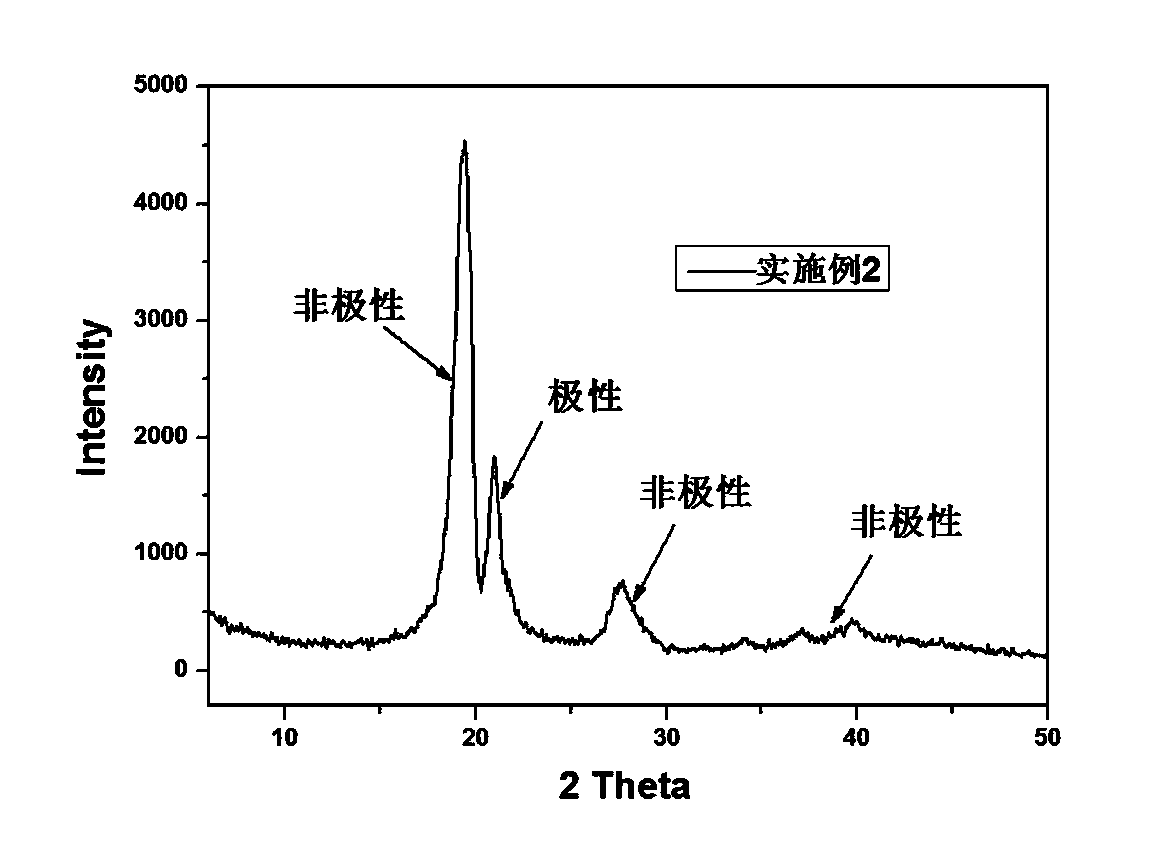

Embodiment 2

[0038] PVDF (viscosity average molecular weight M v =254,000g / mol) and ethanol are dissolved in dimethylformamide (DMF) at 80°C, the mass ratio of raw materials is PVDF:DMF:ethanol=15:82:3, stir until PVDF is completely dissolved, and let stand After defoaming, scrape it on a clean and flat glass plate with a scraper, and expose it to the air for 1 hour to evaporate. Immerse the scraped film solution in the first gel bath for 20 minutes, the temperature of the first gel bath is 40°C, the composition of the first gel bath is: an aqueous solution with a mass percentage concentration of 50% methanol to obtain a nascent film . The nascent membrane was then immersed in a second gel bath containing only deionized water at 20°C for 24 hours. Finally, the membrane was immersed in the third gel bath: an aqueous solution with a mass percent concentration of 10% ethanol for 24 hours. Dry the rinsed membrane at 20°C to obtain an ultrafiltration membrane with a certain crystal conforma...

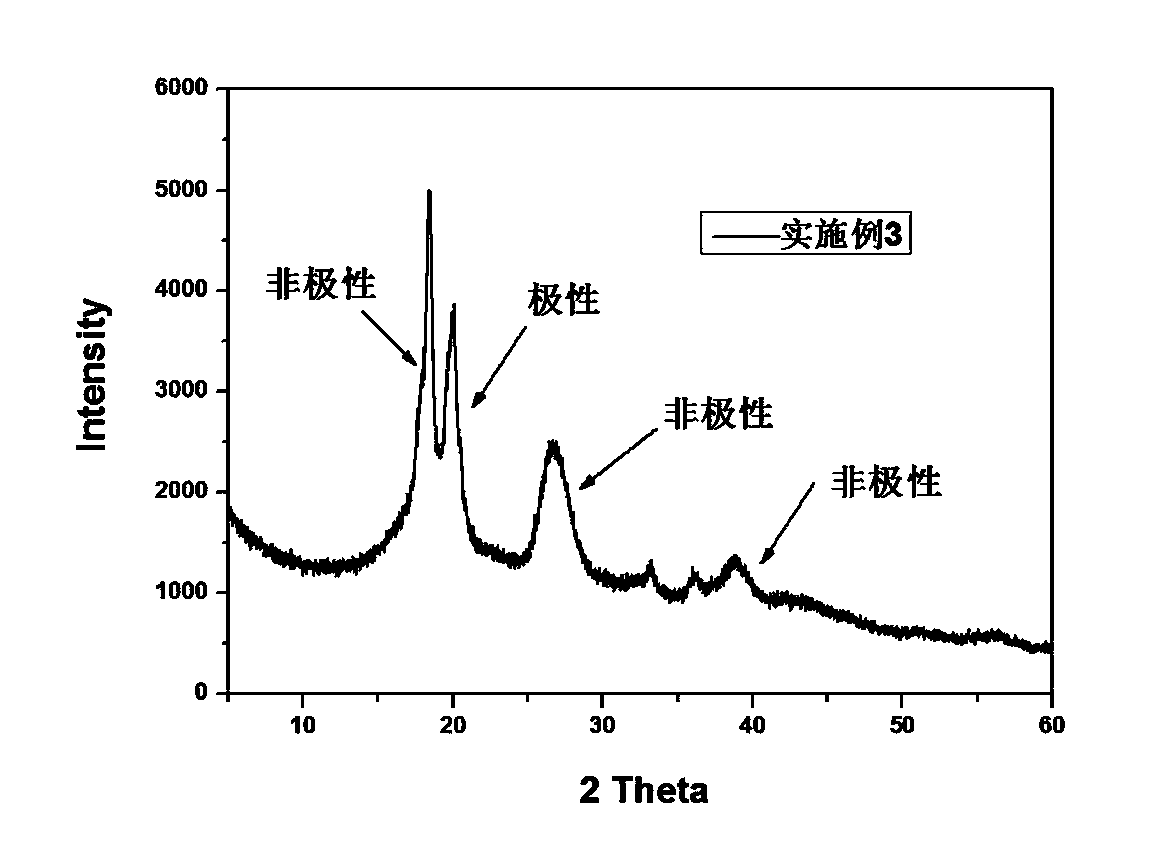

Embodiment 3

[0043] PVDF (viscosity average molecular weight M v=431,000g / mol) and LiCl are dissolved in dimethylacetamide (DMAC) at 80°C, the mass ratio of raw materials is PVDF:DMAC:LiCl=15:83:2, stir until PVDF is completely dissolved, and let stand After degassing, scrape it on a clean and flat glass plate with a scraper, and expose it to the air for 2 hours to evaporate. Immerse the scraped film solution in the first gel bath for 30 minutes, the temperature of the first gel bath is 60°C, the composition of the first gel bath is: the mass percentage concentration is 10% propanol (mass percentage concentration can also be used Replaced by 10% isopropanol) in aqueous solution to obtain nascent membranes. The nascent membrane was then immersed in a second gel bath containing only deionized water at 30°C for 24 hours. Finally, the membrane was immersed in the third gel bath: an aqueous solution with a mass percent concentration of 20% glycerol for 24 hours. Dry the rinsed membrane at 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com