Dynamic rod carving method utilizing power measuring range detector and taking signal as signal source

A technology of power range and dynamic rod marking, which is applied in the field of nuclear reactor physical tests, can solve problems such as troubles and accidental shutdown of the reactor, and achieve the effects of strong measured current, high signal-to-noise ratio, and avoidance of accidental shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

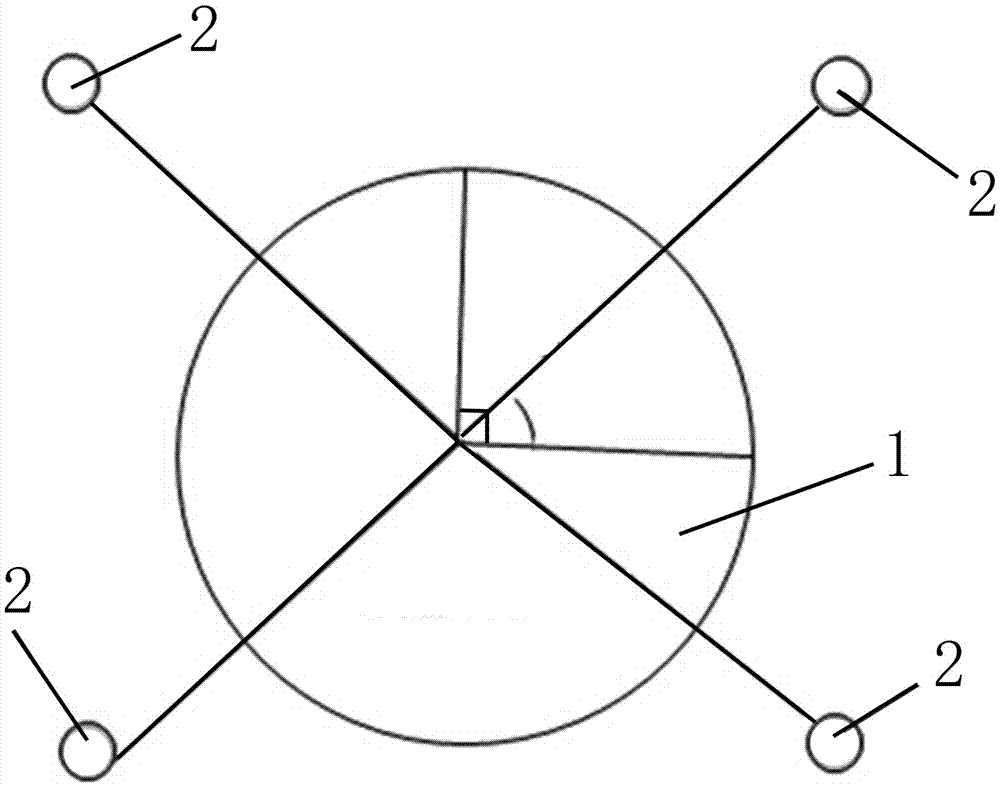

[0053] see figure 1 . 1 is the reactor body, and 2 is the power range detector. It can be seen that detectors with four channels are evenly arranged outside the reactor.

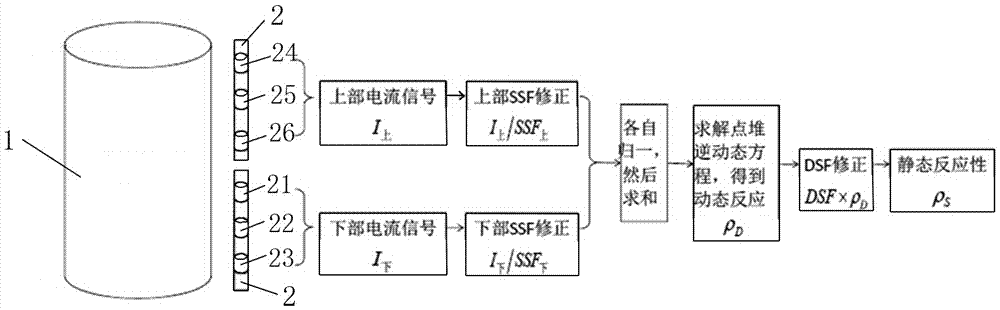

[0054] see figure 2 . In the prior art, the power range detector 2 of one channel includes six detectors, respectively 21~26, wherein the sum of the currents of 21~23 is output as the lower current signal, and the sum of the currents of 24~26 is used as the upper current The signal outputs are respectively corrected by the static correction factor, then normalized and summed, and then calculated.

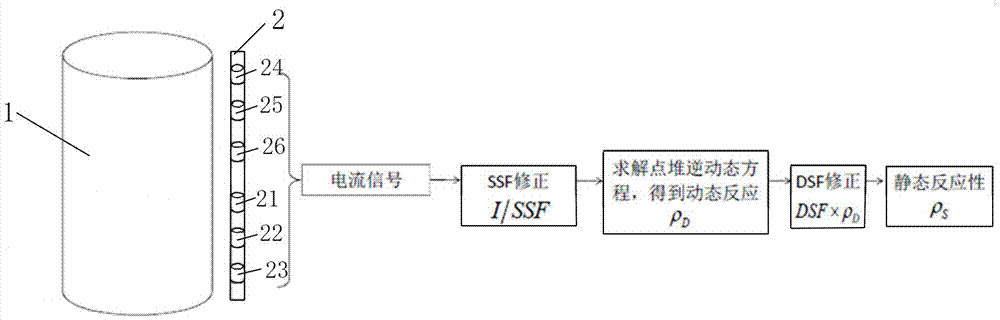

[0055] see image 3 . In the present invention, the power range detector 2 of one channel also includes six detectors 21-26, and the sum of all currents is output as a current signal, which is calculated after being corrected by a static correction factor.

[0056] see Figure 4 to Figure 7 , is an example of the value scale test of a certain group of control rods in a nuclear power plant according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com