Aqueous ink for ball-point pen using oil-in-water type resin emulsion and ball-point pen using the aqueous ink

An oil-in-water type ballpoint pen technology, applied in the field of water-based ballpoint pens and inks for water-based ballpoint pens, can solve the problems of inability to write, low masking, low sunlight tolerance, etc., and achieves excellent drying properties and prevents ink from drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

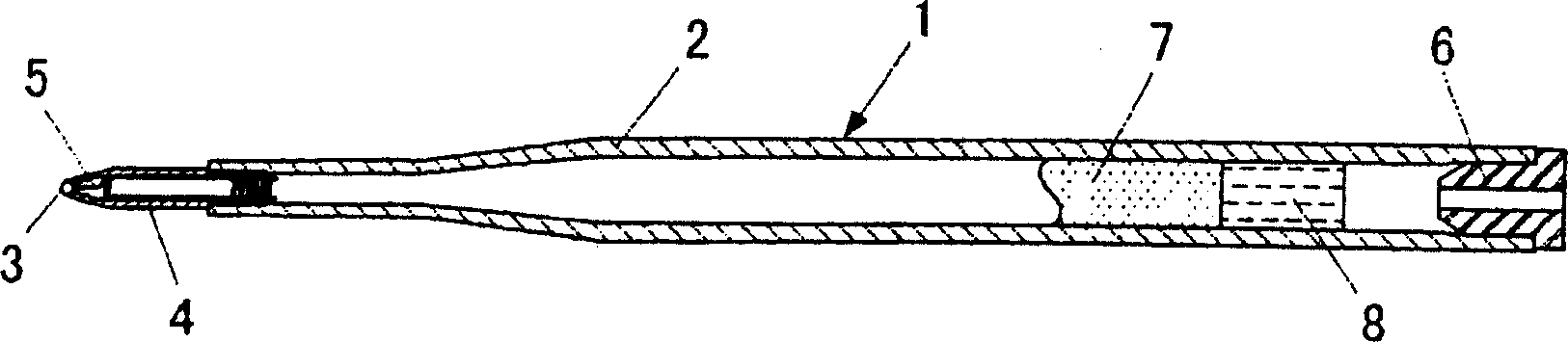

Image

Examples

Embodiment 1

[0051] Pigment black 7 5.0% by weight

[0052] Water-soluble resin (trade name: HPD-96)

[0053] Acrylic resin 4.0% by weight

[0054] Isopropanol (4.3kPa / 20°C) 5.0% by weight

[0055] Water 86.0% by weight

[0056] Anti-rust lubricant (trade name: A-215C) 0.5% by weight

[0057] Triethanolamine 1.0% by weight

[0058] Oil-in-water resin emulsion (trade name: Jion Clear 7001)

[0059] Acrylic emulsion 1.5% by weight

[0060] Wettability improver (trade name: Dynoll 604) 0.8% by weight

[0061] 1,2-Benzisothiazolin-3-one 0.2% by weight

[0062] Pigment Pigment Black 7 as a colorant, water as a solvent, and acrylic resin with a molecular weight of 16,500, a glass transition point of 102°C, and an acid value of 240 as a water-soluble resin that has both pigment dispersing function and handwriting fixing performance. Trade name In HPD-96 (manufactured by Johnspon Polymer Co., Ltd.), predetermined amounts of each component were accurately weighed, and the pigment was unifor...

Embodiment 2

[0064] The green pigment Pigment Green 7 used as a colorant, the styrene acrylic emulsion with a minimum film forming temperature of 15°C as a handwriting fixation and water resistance improver, trade name Jionclell 775 (manufactured by JionSompolima Co., Ltd.), except Except as shown in Table 1, operate in the same manner as in Example 1 to obtain inks for water-based ballpoint pens with green handwriting and appearance. In addition, for the product names HPD-96 and Jion Clear 775, consider the amount of effective solid content. design. In addition, the viscosity of the ink at 20° C. was 10.0 mPa·s.

Embodiment 3

[0066] As a handwriting fixation and water resistance improver, a vinyl acetate-based emulsion with a minimum film-forming temperature of 16°C or below, trade name Boncoat 2610 (manufactured by Dainippon Inki Chemical Industry Co., Ltd.), was used as a solvent at a vapor pressure of 20°C. Be the ethanol of 5.9kPa as alcoholic solvent, except as shown in table 1, operate similarly with embodiment 1, obtain handwriting, outward appearance all be the ink for water-based ball-point pen of green, in addition, for trade name HPD-96, ボンコ one ト2610, consider the amount of effective solids to design the ink. In addition, the viscosity of the ink at 20° C. was set to 15.0 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com