Preparation method of nano silver chloride/chitosan fiber anti-bacterial dressing

A technology of chitosan fiber and silver chloride, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of poor particle fixation performance, difficult selective adsorption of silver ions, and easy fall-off, etc., to achieve good fixation performance and effective Favorable for selective adsorption and reduced accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Surface pretreatment of chitosan non-woven fabric

[0034] Take the chitosan fiber non-woven fabric (120 g / m 2 ) 10*10cm 2 , Respectively immersed in nitric acid + acetic acid and nitric acid + acetic acid + surfactant solutions to pretreat the fiber surface. The pretreatment conditions are shown in Table 1.

[0035] Table 1 Surface pretreatment conditions of chitosan fiber

[0036]

[0037] Surfactants 1, 2, and 3 are respectively used: alkanolamide, dodecylbenzene sulfonic acid, fatty alcohol polyoxyethylene ether, the dosage is 0.1-0.5mol / L.

[0038] (1) When the concentration of surfactant 1 is 0.1 mol / L, the acid concentration is 0.001 mol / L, and the acid solution volume is 100 mL for 1 min, the weight loss of chitosan fiber is 1.14%. It can be seen from the scanning electron microscope that the fiber surface has obvious Defect

[0039] (2) When the concentration of surfactant 1 is 0.3 mol / L, the acid concentration is 0.01 mol / L, and the acid solution volume is 50 mL fo...

Embodiment 2

[0048] Impregnation and adsorption of silver salt by chitosan fiber

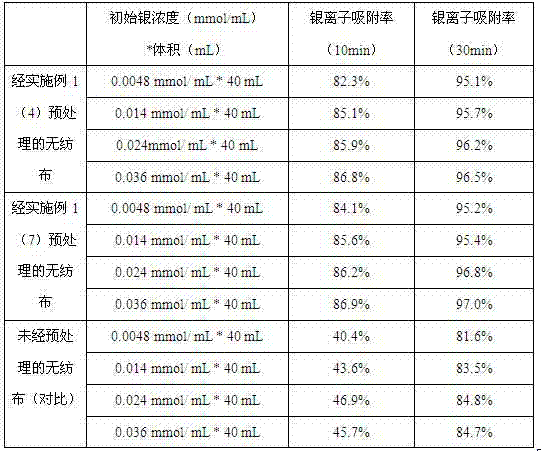

[0049] Take several pieces of pretreated chitosan non-woven fabric (10*10 cm 2 , The pretreatment method is according to Example 1 (4) and (7)), respectively immersed in silver nitrate solutions of different initial concentrations, and regularly sampled to analyze the concentration of residual silver ions in the solution. Chitosan without pretreatment Non-woven fabric as a control sample;

[0050] The pre-treated chitosan fiber shows selective adsorption of silver ions. Within the selected silver ion concentration range, the adsorption speed of silver ions is very fast within 10 minutes, and slows down after 20 minutes. The adsorption capacity accounts for 95-97% of the total amount of silver in the solution, reaching the maximum equilibrium adsorption capacity; the samples prepared by the pretreatment methods (4) and (7) in Example 1 show no significant difference in the adsorption rate of silver ions;

[...

Embodiment 3

[0056] Preparation of nano silver chloride / chitosan fiber antibacterial material

[0057] The commonly used antibacterial dressing silver load is 10-150mg / 10*10cm 2 , This work has designed 4 different silver loadings 20, 60, 100, 150 mg / 10*10cm 2 ;

[0058] (1) Pretreat the chitosan non-woven fabric (10*10cm 2 ), immerse in 40mL 0.0048mmol / mL silver nitrate solution, after draining, dry with hot air to 30% water content; evenly spray 8mL of 0.036 mmol / mL sodium chloride solution, chlorination reaction for 5min; deionized water cleaning Then, vacuum dry to prepare the finished product;

[0059] The silver loading of the final product is 19.5mg, the silver recovery rates of the silver nitrate impregnation and chlorination reaction processes are 95.5% and 98.5%, respectively, and the total silver recovery rate is 94.1%.

[0060] (2) The method of (4) in Example 1 is used to pretreat the chitosan non-woven fabric (10*10cm 2 ), immerse in 40mL of 0.014 mmol / mL silver nitrate solution, dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com