Welding fixture for high-low voltage power distribution cabinet production

A technology for welding fixtures and power distribution cabinets, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of manpower consumption and low efficiency, achieve fast fixing speed, improve efficiency, and improve welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

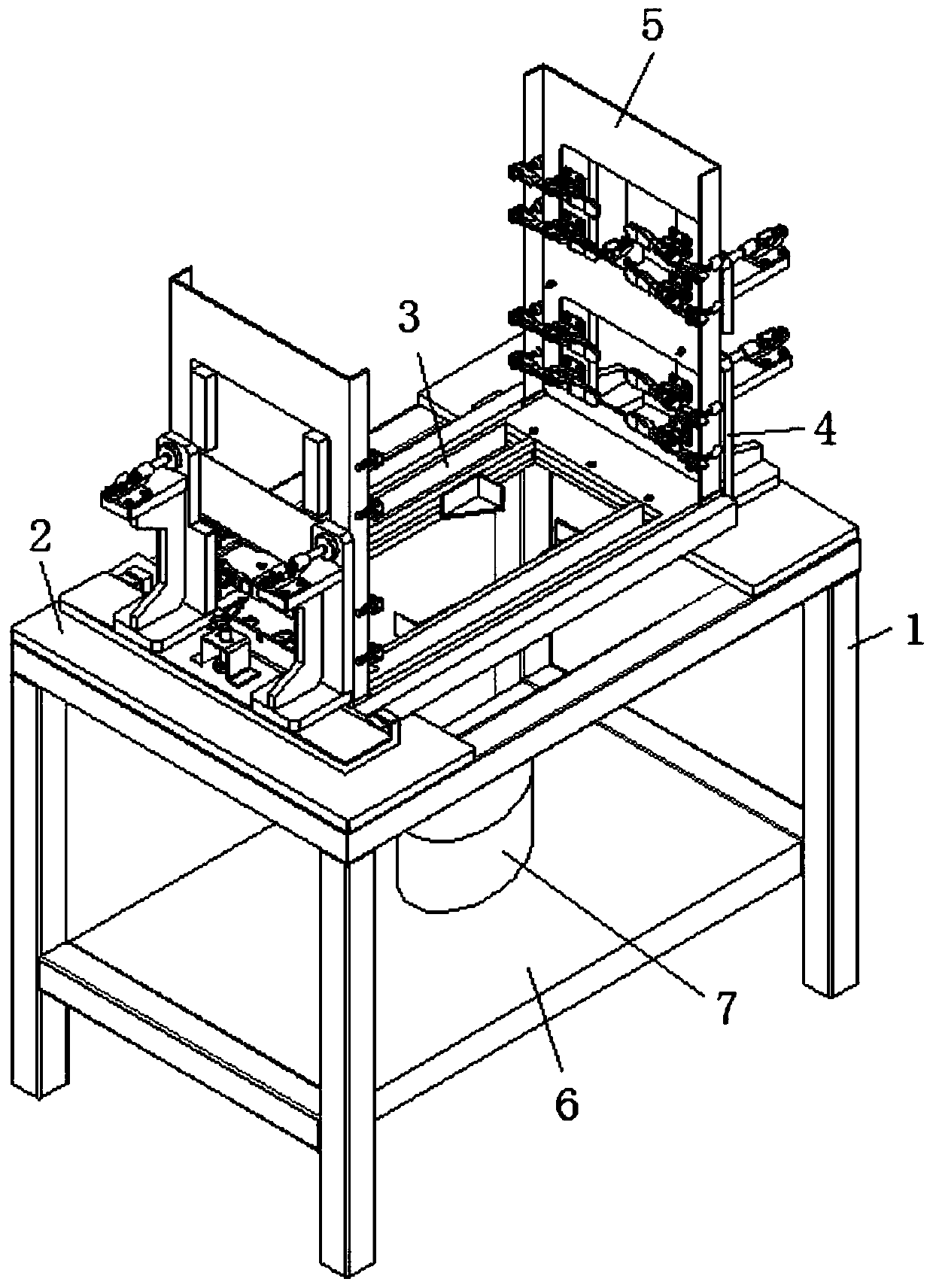

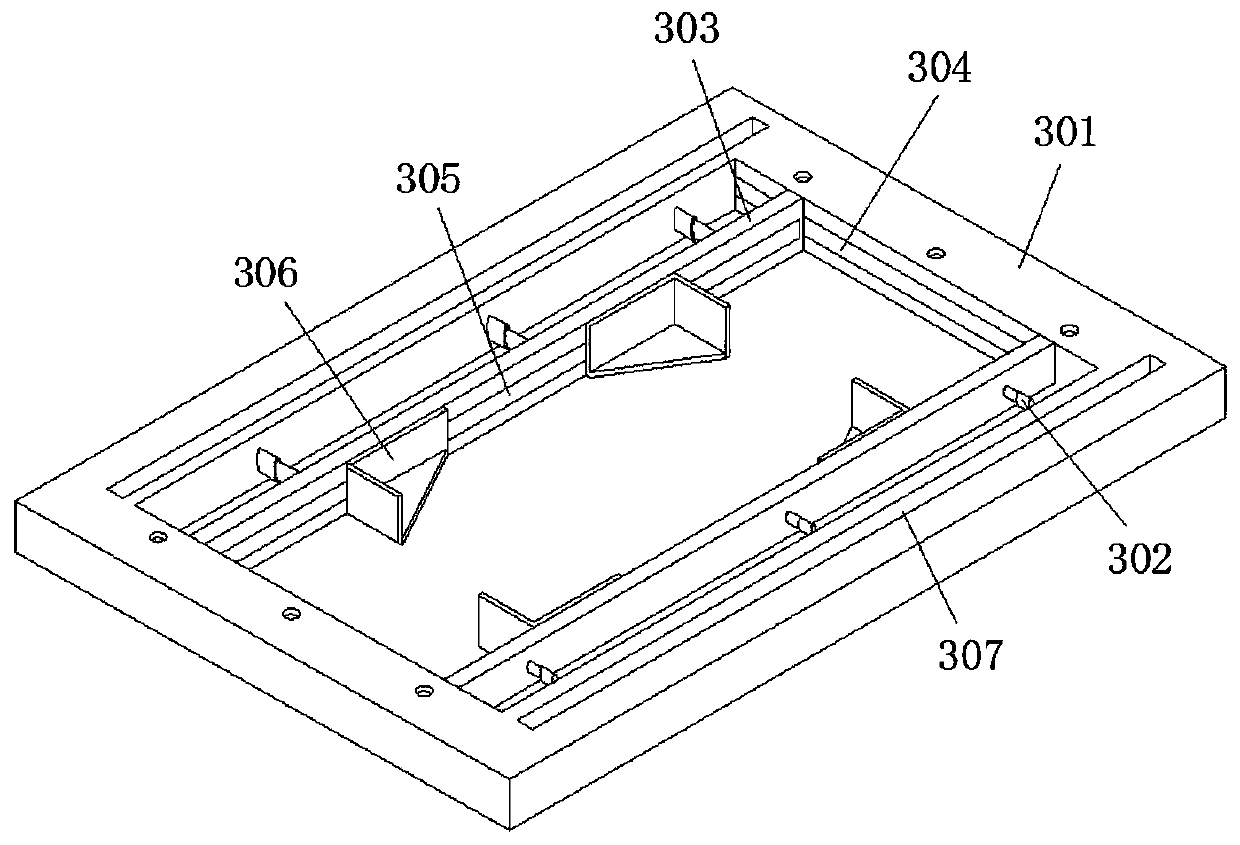

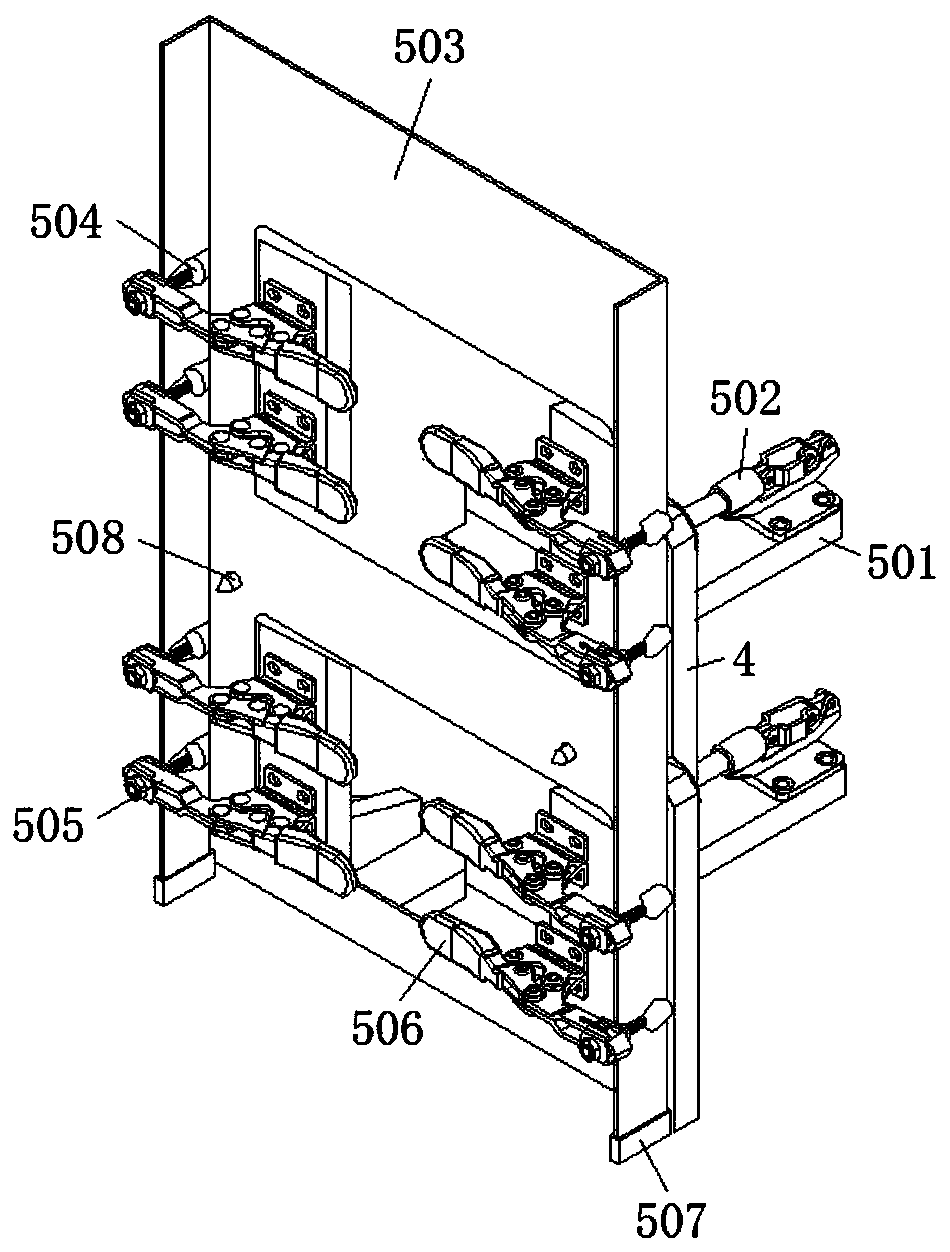

[0029] refer to Figure 1-4 , a welding fixture for the production of high and low voltage power distribution cabinets, including a fixing frame 1, mounting plates 2 are fixedly connected to both sides of the top surface of the fixing frame 1, and a holding mechanism 3 is fixedly connected to the top surfaces of the two mounting plates 2. Mechanism 3 includes a rectangular frame 301, the front and rear end inner walls of the rectangular frame 301 are fixedly connected with electric telescopic rods 302, and the telescopic ends of the electric telescopic rods 302 at the same end are all connected with support bars 303 by screws, and the two sides of the support bar 303 are connected with the rectangular frame 301. The inner walls are connected by sliding contact, and the two support bars 303 are provided with adjustment grooves 305 at one end close to each other. There are right-angle fixing blocks 306 slidingly connected in the adjustment grooves 305, and there are two right-ang...

Embodiment 2

[0033] Such as figure 1 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the rotating mechanism includes a support plate 6, the middle part of the top surface of the support plate 6 is fixed with a servo motor 7 through screws, and the output end of the servo motor 7 is fixed with a mounting plate through screws. Block 8, a cylinder 9 is affixed to the top surface of the installation block 8, and an electromagnet 10 is affixed to the output end of the cylinder 9.

[0034] In this embodiment, the adjustment of the position of the electric control cabinet can be realized through the cylinder 9, so as to facilitate the rotation operation of the electric control cabinet, and further realize the comprehensive welding operation of the electric control cabinet.

Embodiment 3

[0036] Such as figure 1 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the support plate 6 is fixed on the fixed frame 1, and the input ends of the servo motor 7 and the cylinder 9 are electrically connected to the controller, and the top surface of the electromagnet 10 horizontal setting.

[0037] In this embodiment, by electrically connecting the input terminals of the servo motor 7 and the cylinder 9 to the controller, it is convenient to control the working states of the servo motor 7 and the cylinder 9, thereby realizing automatic production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com