Separation making process of mixed slurry of raw slurry and boiled slurry of dried bean curd

A production process and technology of raw and cooked pulp, applied in the field of separation and production of dried tofu raw and cooked pulp mixed pulp, can solve the problems of difficult water extraction, expensive, easy to block filter screens, etc., to improve mechanization procedures, increase labor productivity, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

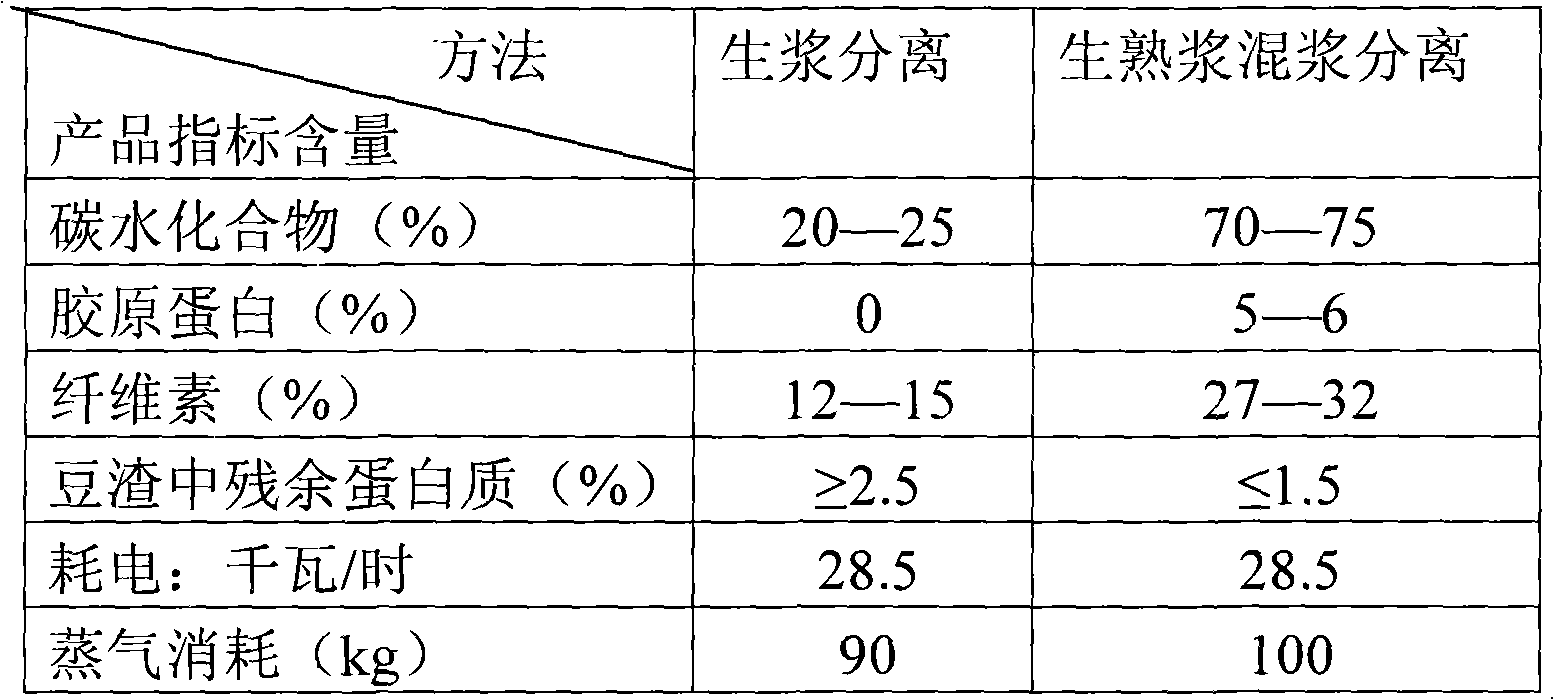

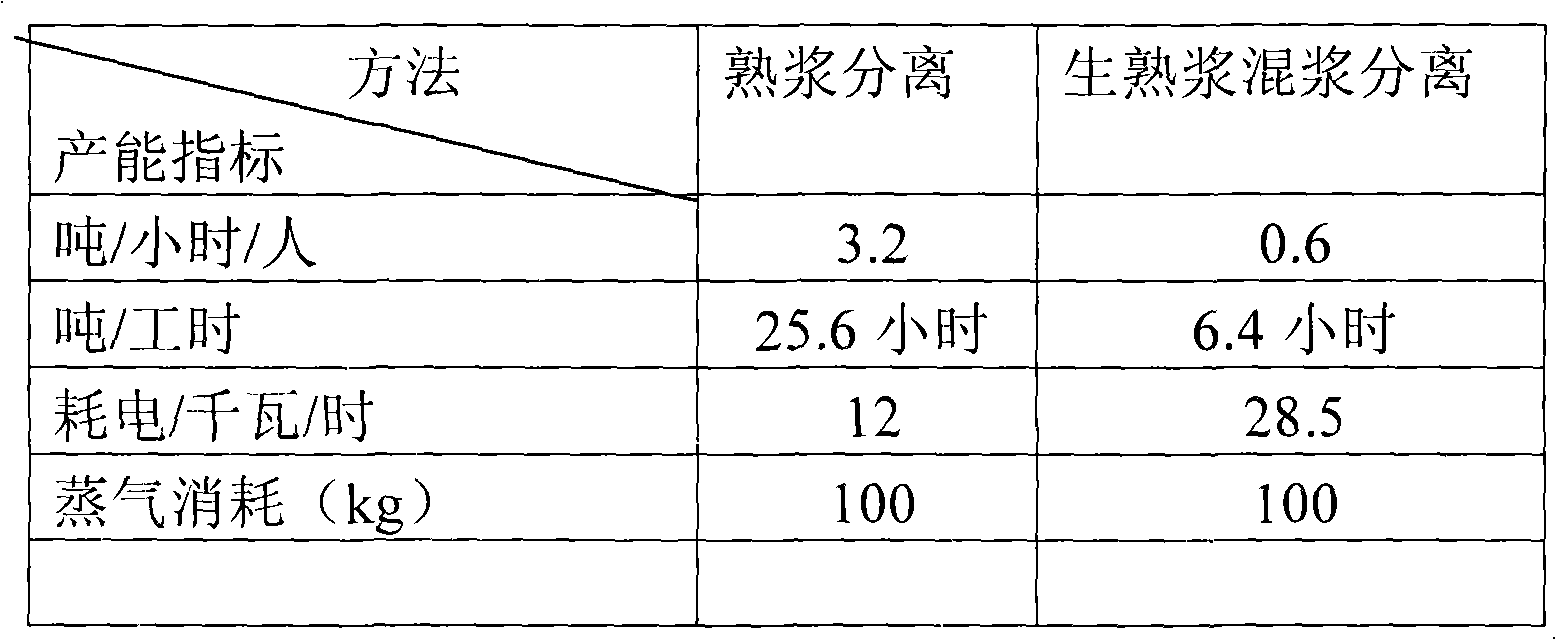

[0015] Get 300kg of soaked soybeans, use a 300-type refiner to grind, add 600-660kg of clear water while grinding, and the grinding time is 30 minutes to form 900-960kg of original pulp, the viscosity of the original pulp is 80mpa.s.

[0016] The obtained puree is separated once:

[0017] The equipment used for the separation is 3 sets of WXCJ560 centrifuges, and the separation time is 30 minutes, which is carried out continuously, and temporary parking is minimized. After separation, 300-350kg of bean dregs and 600-660kg of raw pulp are obtained after separation.

[0018] Add 200-250kg of water to the primary bean dregs to boil, and then perform secondary separation. The separation time is matched with the previous process. After separation, 160-200kg of secondary bean dregs and 400-450kg of secondary cooked pulp are obtained.

[0019] After the primary raw pulp and the secondary cooked pulp are mixed and boiled, the subsequent processes such as pulping, pressing, cutting an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com