Alkyl-blocked alkylphenol polyoxyethylene ether benzene sulfonate surfactant and preparation method and application thereof

A technology of terminal alkylphenol polyoxyethylene ether and surfactant, which is applied in the field of alkyl-capped alkylphenol polyoxyethylene ether benzenesulfonate surfactant and its preparation, and can solve the problem of polyoxyethylene benzenesulfonic acid There are few problems such as salt research, and the effect of excellent surface/interface performance, high surface activity and high yield is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

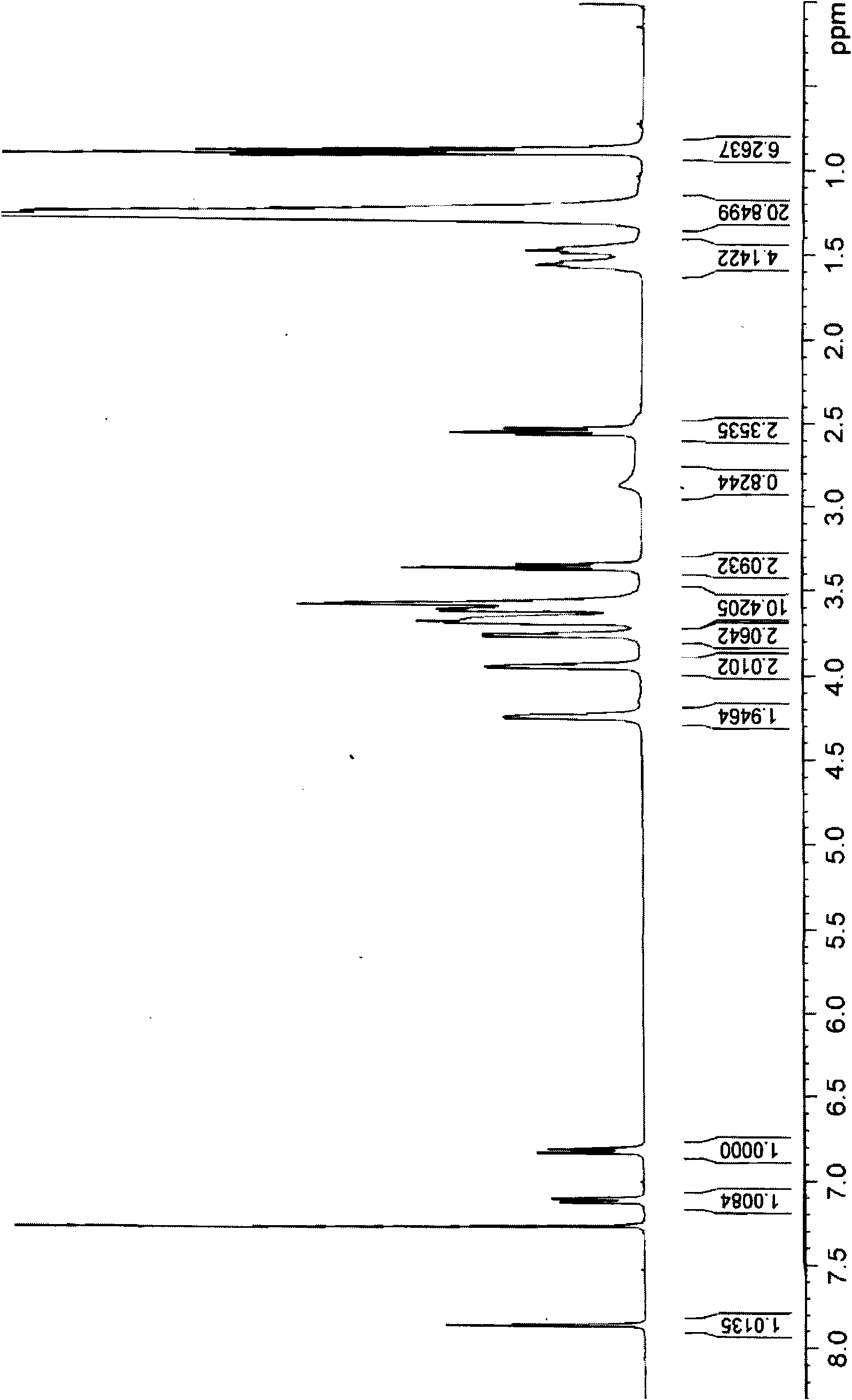

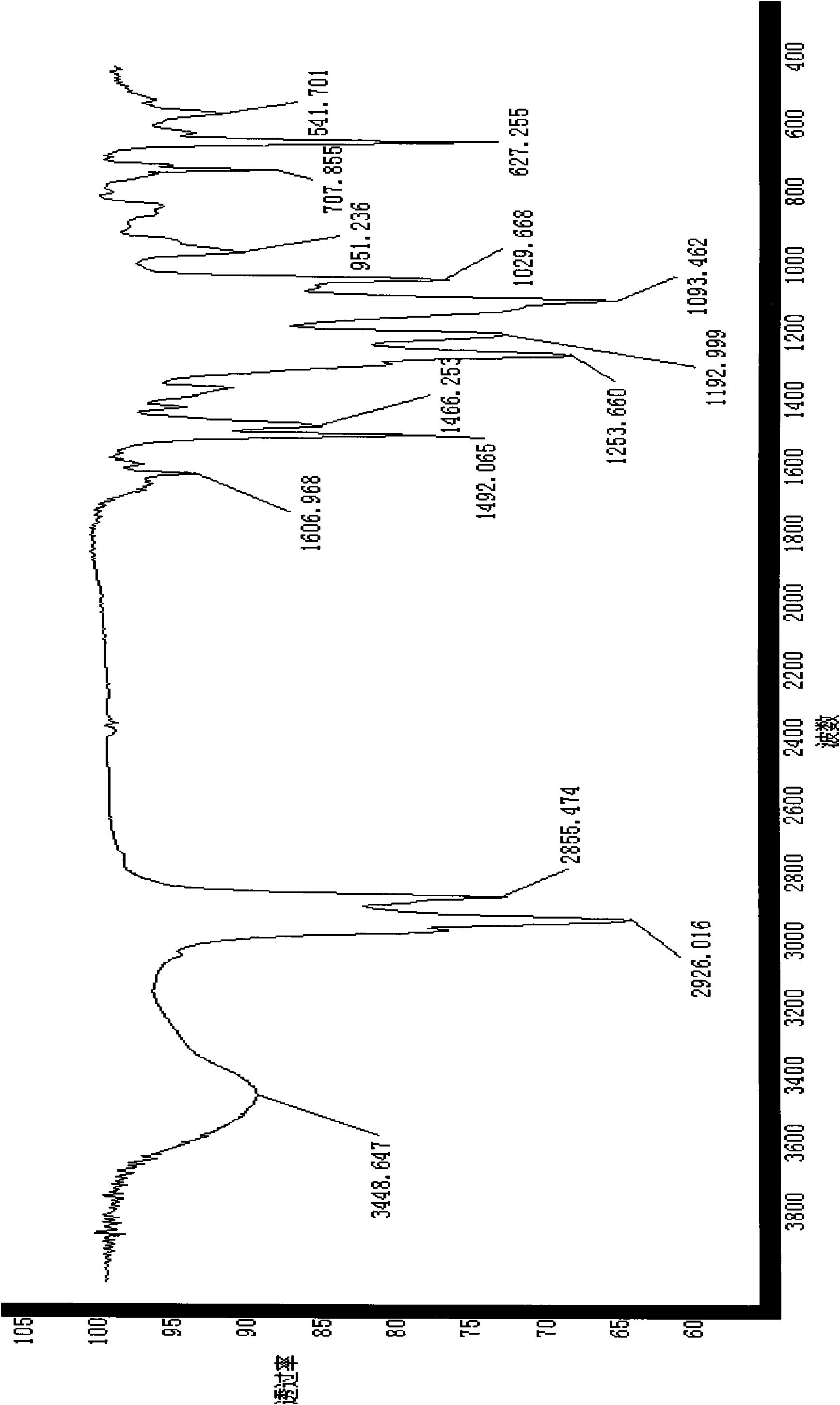

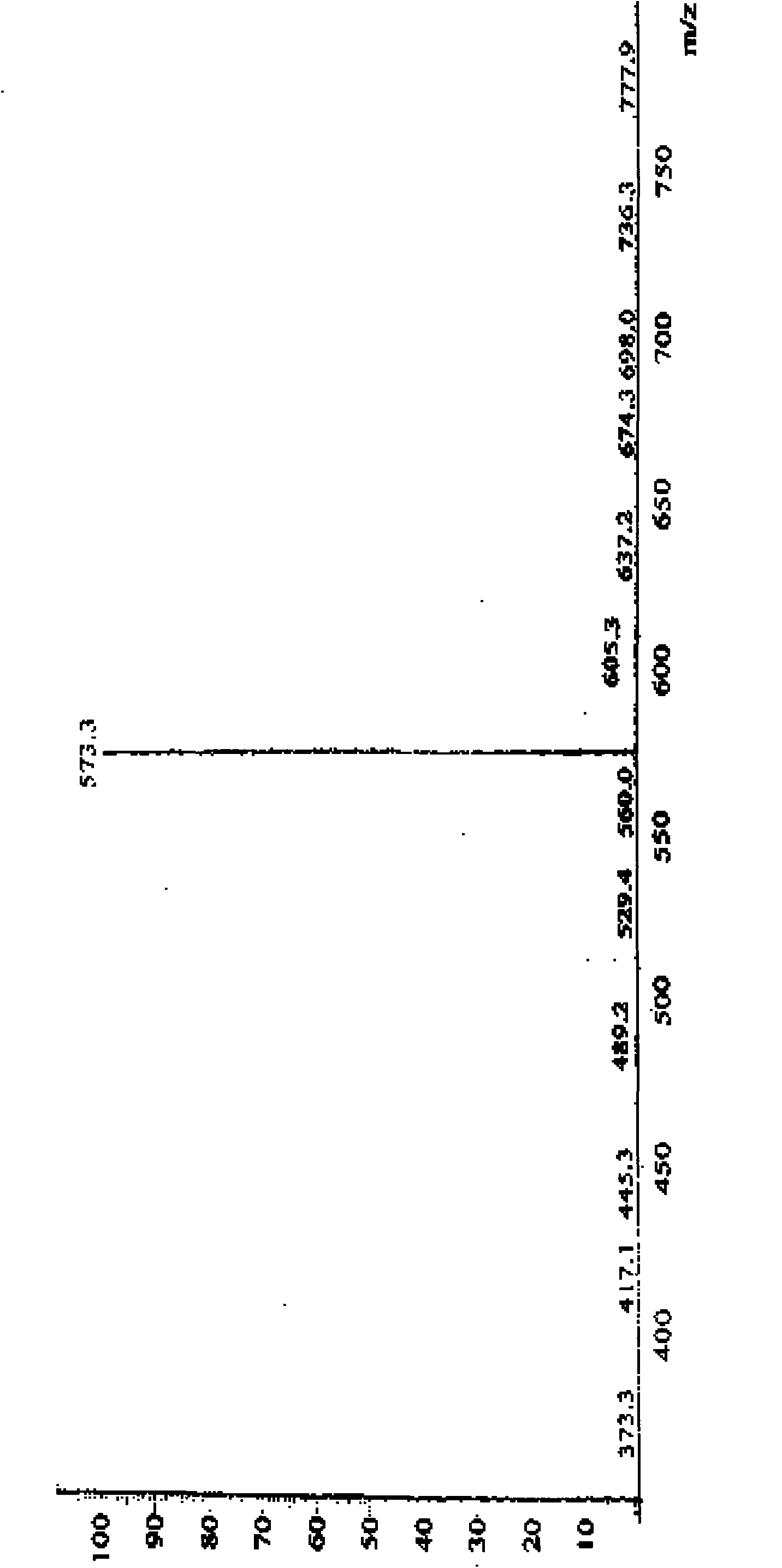

Image

Examples

Embodiment 1

[0059] Example 1 Preparation of octyl-terminated octylphenol polyoxyethylene (4) ether sodium benzenesulfonate

[0060] (1) Add 15.35 g (0.05 mol) of octyl polyoxyethylene (4) alcohol and 1 mL of dimethylformamide to a 100 mL flask equipped with electromagnetic stirring, thermometer, reflux condenser, drying tube, and constant pressure dropping funnel At room temperature, slowly add 7.14g (0.06mol) of thionyl chloride through a constant pressure dropping funnel, continue to react for 0.5 hours after the dropwise addition, then raise the temperature to 120°C for 2 hours, pour into saturated sodium carbonate after cooling 300mL petroleum ether for three extractions, washed the organic phase three times with water, then dried the extracted petroleum ether phase with anhydrous sodium sulfate, rotary evaporated to remove the petroleum ether, and then distilled under reduced pressure to collect 184~186℃ / 532Pa 12.98 g of octyl polyoxyethylene (3) ethyl chloride was obtained from the ...

Embodiment 2

[0064] Example 2 Preparation of sodium dodecane-terminated octylphenol polyoxyethylene (6) ether benzenesulfonate

[0065] Add 4.70 g (0.01 mol) of octylphenol polyoxyethylene (6) ether (OP-6) and 1 mL of pyridine into a 100 mL flask equipped with electromagnetic stirring, a thermometer, a reflux condenser, a drying tube, and a constant pressure dropping funnel. Slowly add 1.79g (0.015mol) of thionyl chloride through a constant pressure dropping funnel at room temperature, continue to react for 0.5 hours after the dropwise addition, then raise the temperature to 100°C for 2 hours, pour into saturated sodium bicarbonate after cooling In the ice water solution of 300mL ethyl acetate, extract three times, wash the ethyl acetate phase three times, then dry the extracted ethyl acetate phase with anhydrous magnesium sulfate, and then rotary evaporate to remove the ethyl acetate to obtain octyl polyoxyethylene (5) 4.25 g of ethyl chloride, the yield is 87.0%. Then add 1.86g (0.01mol...

Embodiment 3 10

[0068] Embodiment 3 Preparation of dodecane-terminated octylphenol polyoxyethylene (15) ether sodium benzenesulfonate

[0069] Add 8.66g (0.01mol) of octylphenol polyoxyethylene (15) ether (OP-15) and sodium hydroxide to a 100mL flask equipped with electromagnetic stirring, thermometer, reflux condenser, drying tube, and constant pressure dropping funnel 0.60g (0.015mol), react at 100°C for 1 hour, then gradually add 2.49g (0.01mol) of brominated n-dodecane dropwise, heat to reflux for 2-5 hours after the dropwise addition, add 100mL of petroleum Extract with ether and 60mL water, extract the aqueous phase with petroleum ether until the petroleum ether layer is colorless, combine the organic phases, wash the organic phases with water three times, dry the organic phases with anhydrous magnesium sulfate, and evaporate the solvent to obtain dodecyl-capped octylphenol Polyoxyethylene (15) ether 7.94g, its yield 76.8%.

[0070] Add 20 mL of dried and refined 1,2-dichloroethane and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com