Gear ring length dimension gauge

A size and inspection tool technology, which is applied in the field of inspection tools for measuring the length and dimension of thin-walled ring gears, can solve problems such as unfavorable production site quality management, high requirements for inspection conditions, and lack of effective inspection tools, and is conducive to quality management and measurement. Intuitive results, the effect of avoiding batch scrapping accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

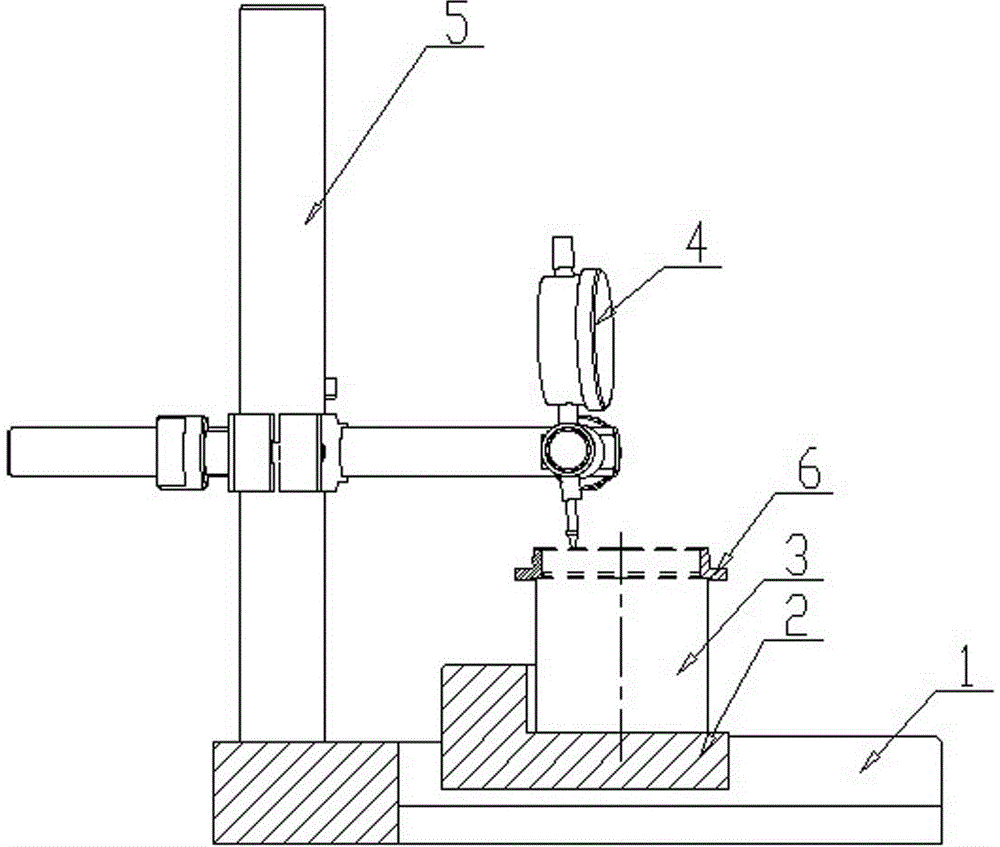

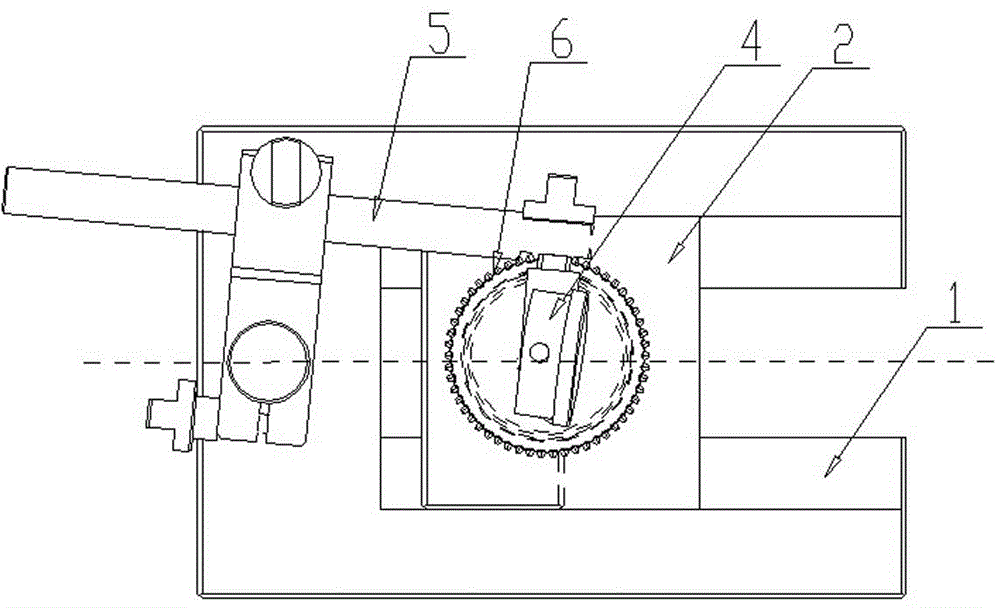

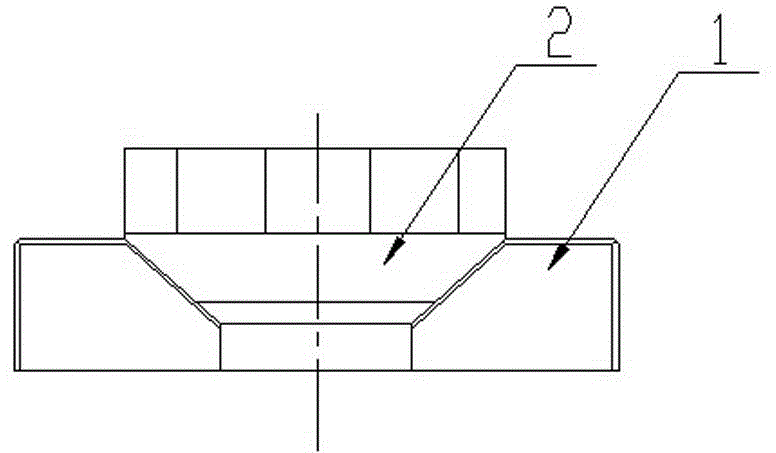

[0019] figure 1 and figure 2 The ring gear length dimension inspection tool shown includes a base 1, a slider 2, a shaft seat 3, a meter 4 and a meter frame 5. The table frame 5 is made up of cross-connected vertical bars and cross bars, and the vertical bars are connected to the base. The base 1 is the main body component, it is a kind such as image 3 and Figure 4 As shown in the rectangular plate, a built-in opening slot is provided in the middle length direction of the plate surface, and upward slopes are provided on both sides of the opening slot. The slider 2 is a right-angled member, and the bottom surface cooperates with the upward slopes on both sides of the opening groove of the base 1 to form a straight track structure. The cross section of the straight track in this embodiment is V-shaped. A V-shaped groove perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com