Mechanical zero adjusting device of steering engine

A technology of mechanical zero position and adjustment devices, which is applied in the direction of adopting mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems of low work efficiency, no measuring tools, no measuring reference, etc., and achieve simple structure, simple measurement operation, Intuitive effect of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

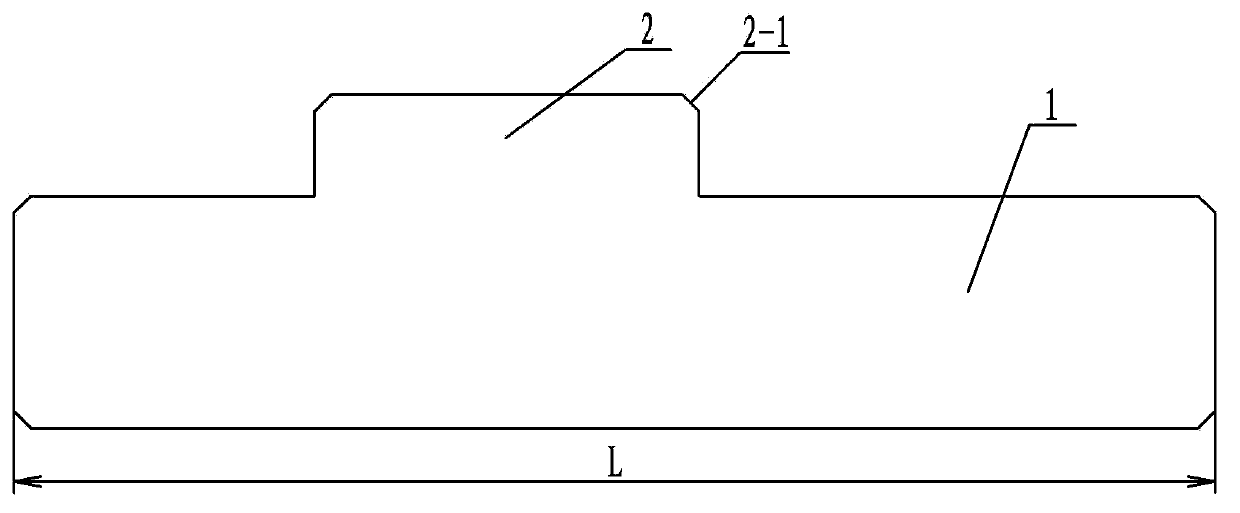

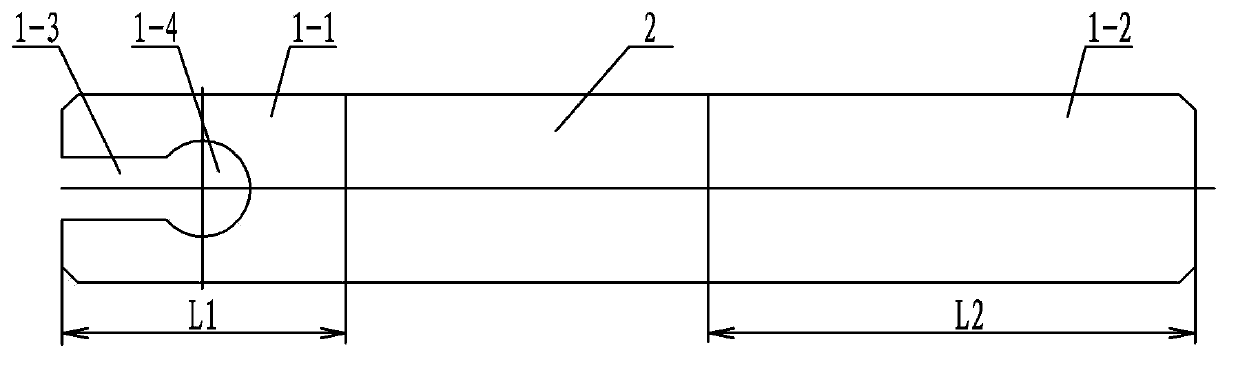

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes detection block 1 and positioning block 2, the cross-section of detection block 1 and positioning block 2 is rectangular, positioning block 2 and detection block 1 are set up and down and made into one, positioning block 2 The part between one end of the detection block 1 is the detection end 1-1, the part between the positioning block 2 and the other end of the detection block 1 is the non-detection end 1-2, and the outer end surface of the detection end 1-1 is edge detection A long slot 1-3 is provided in the length direction of the end 1-1, and a pin hole 1-4 communicating with the long slot 1-3 is provided in the detection end 1-1 along the thickness direction. The length L of the detection block 1 is the same as the diameter of the output shaft 4 on the steering gear 3 . The width of long slot 1-3 is slightly larger than the diameter of positioning ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Referring to this embodiment, chamfers 2-1 are provided at the intersections between the upper end surface of the positioning block 2 and the four side walls in this embodiment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 The present embodiment will be described. In this embodiment, the length L1 of the detection end 1-1 is smaller than the length L2 of the non-detection end 1-2. Other compositions and connections are the same as those in Embodiment 1 or 2.

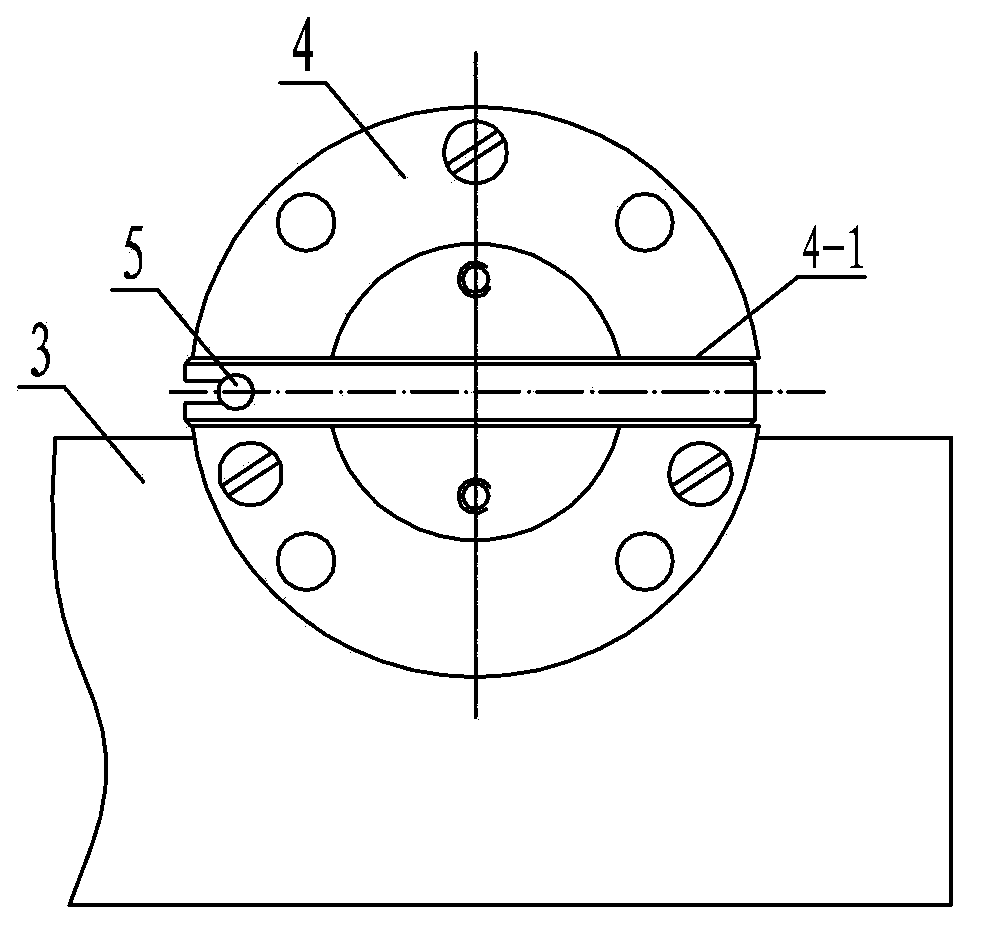

[0010] Using method of the present invention: see image 3 and Figure 4 , first put the detection block 1 into the rectangular groove 4-1 on the output shaft 4 of the steering gear, and rotate the output shaft 4 until the positioning pin 5 on the steering gear 3 can pass through the pin hole 1-4 on the detection block 1 smoothly , it is determined that the mechanical zero position of the steering gear is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com