Forging process of engine crankshaft

An engine and process technology, applied in the direction of engine components, mechanical equipment, etc., can solve the problems of weakening the strength of the crankshaft, discontinuity of the essential grain fibers, etc., and achieve the effect of less investment in tooling and auxiliary tools, long service life, and good forging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A forging process for an engine crankshaft, comprising the following steps:

[0017] 1), the first fire: Press the pliers to take the bar stock %430×500, gnaw the bottom, upsetting to a height of 900, pull out #750, and the length is about 1715;

[0018] 2) Upsetting to a height of 850, drawing to a hexagonal height of 650, a length of about 2140, and a stamping depth of 120;

[0019] 3), the third fire: use 120 degrees up and down V-shaped anvil to make a wrong turn, the wrong shift amount is 170, trim and straighten;

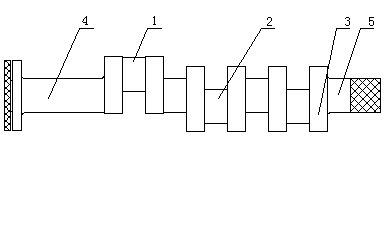

[0020] 4) Press the crutch (2) first, then use a square ruler to determine the angle, then press the crutch (3) to 550×460, and then press the crutch (1) to 550×460;

[0021] 5), number stamp, press out the small shaft (5) at the bottom end, and press out the small shaft (4) between the flange and the turning (1);

[0022] 6) Round the flange to the process size. After the size is in place, check the relative angle of each turn with a square, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com