Manual tile cutter with improved rotating square

A technology for cutting machines and ceramic tiles, which is applied in the direction of manufacturing tools, stone processing tools, work accessories, etc., and can solve the problems of increasing the longitudinal extension of cutting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

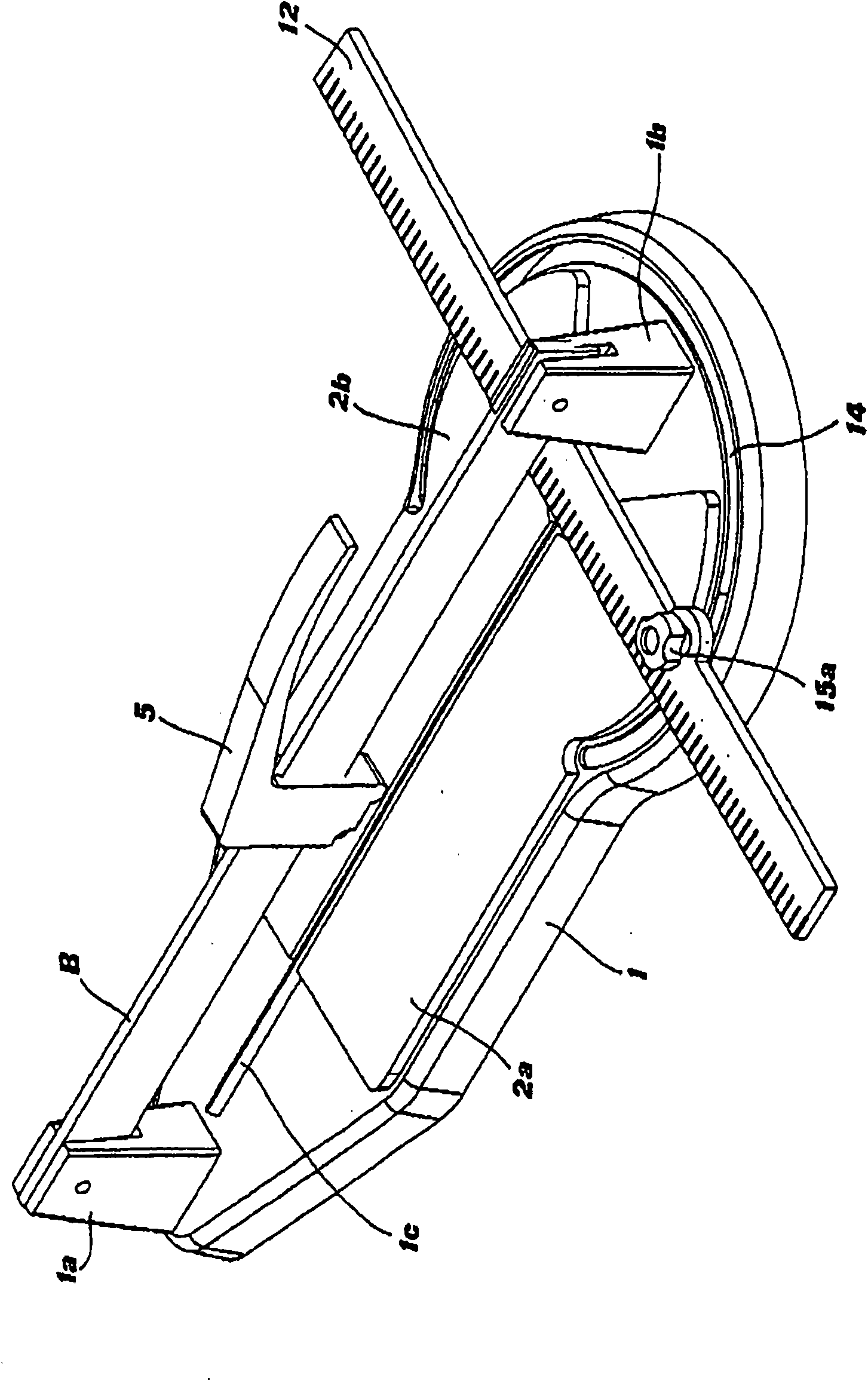

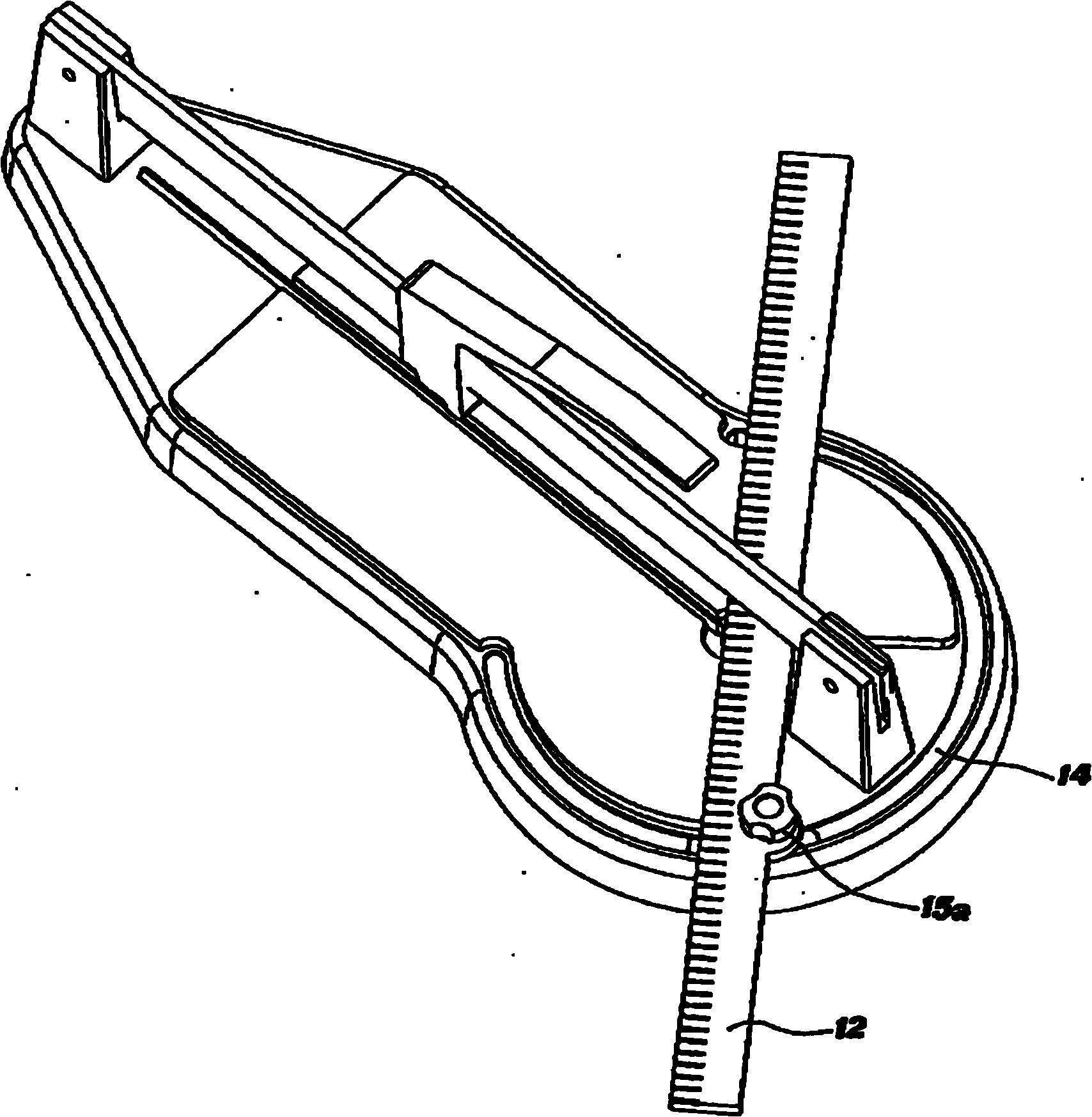

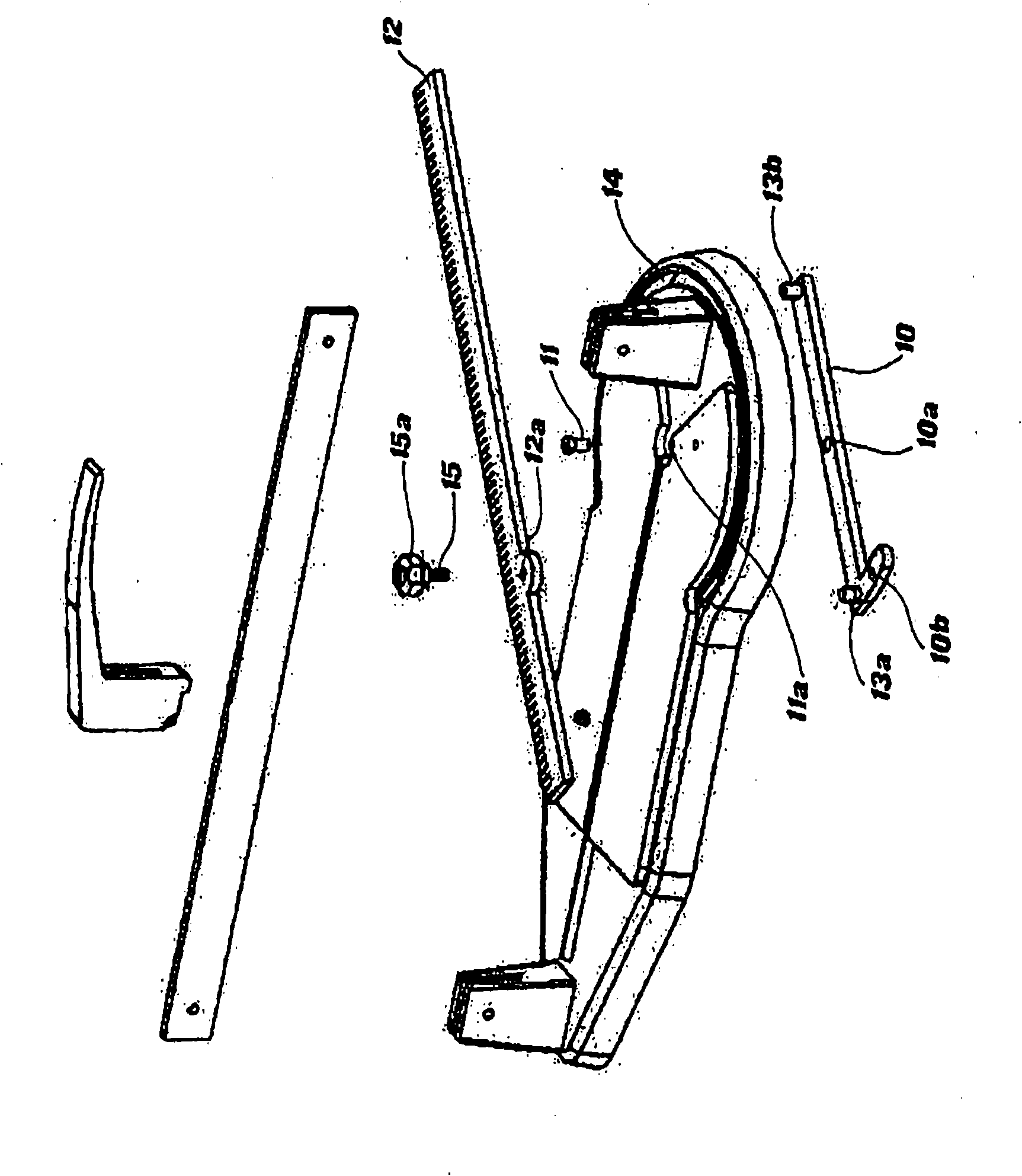

[0026] Such as figure 1 It can be seen that the tile cutter comprises, in a manner known per se, a base 1, for example die-cast from an aluminum alloy, from which protrude first and second columns 1a and 1b, on which a translation guide B is mounted. between the first and second columns 1a and 1b. Two floating support plates 2a and 2b are installed on the upper plane of the base 1, and the floating support plates 2a and 2b constitute the support plane of the ceramic tile to be cut.

[0027] A knife holder 5 is slidably guided on the translation bar B, on which a cutting tool, such as a special steel cutting wheel (not shown), is provided. The coupling between the tool holder 5 and the translating guide B also determines the placement of the cutting line, which is generally arranged directly below and along the longitudinal axis of the guide B, directly below the longitudinal axis of the guide B and Along the longitudinal axis of the guide rail B there is also a split rib 1c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com