Permeable crystalline waterproof coating

A technology of waterproof coating and osmotic crystallization, applied in the field of osmotic crystalline waterproof coating and composition, can solve the problems of fading and peeling, low adhesion, shortened coating life, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

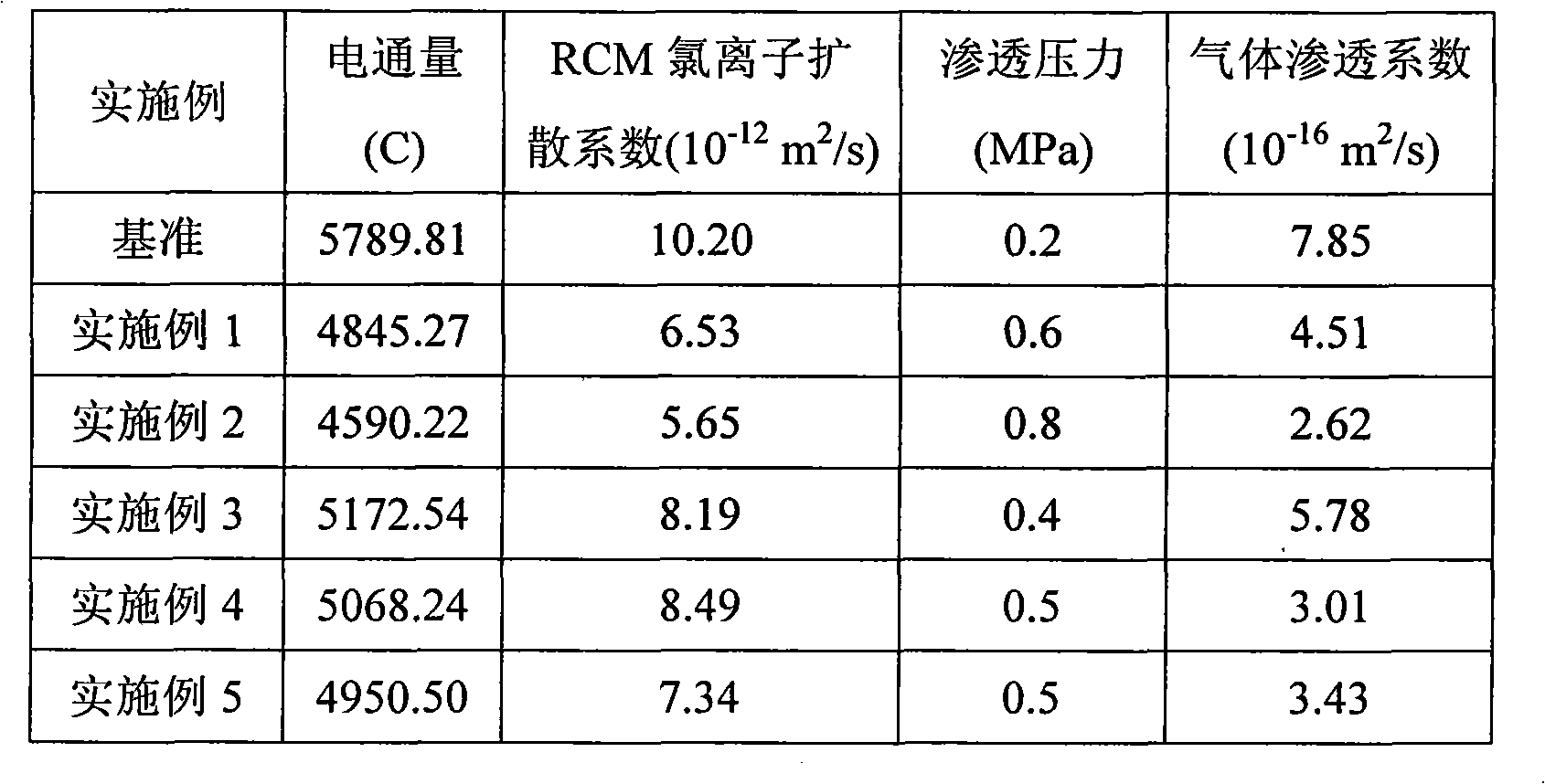

Examples

Embodiment 1

[0046] The weight percent of each component of the present embodiment is:

[0047] Portland cement 45%

[0048] Quartz sand 40%

[0049] Filler 5%

[0050] Calcium Ionic Compound 2%

[0051] Crystal Precipitant 2%

[0052] Complexing Aid 1.5%

[0053] Coalescent 3%

[0054] Complexing agent 0.4%

[0055] Polycarboxylate superplasticizer 0.8%

[0056] Methylcellulose 0.3%

[0057] Among them, the filler is fly ash, the calcium ion compound is dihydrate gypsum, the crystal precipitant is nano-scale sodium silicate, the complexing aid is stearic acid, the film-forming aid is polyvinyl acetate, and the complexing agent is butyl acrylate. ester.

Embodiment 2

[0059] The weight percent of each component of the present embodiment is:

[0060] Portland cement 42%

[0061] Quartz sand 30%

[0062] Filler 16%

[0063] Calcium Ionic Compound 3%

[0064] Crystal Precipitant 2%

[0065] Complexing Aid 3%

[0066] Coalescent 1%

[0067] Complexing agent 1.2%

[0068] Polycarboxylate superplasticizer 1.6%

[0069] Methylcellulose 0.2%

[0070] The filler is silica fume, the calcium ion compound is calcium hydroxide, the crystal precipitant is nano-scale sodium silicate, the complexing aid is stearic acid, the film-forming aid is polyvinyl acetate, and the complexing agent is butyl acrylate .

Embodiment 3

[0072] The weight percent of each component of the present embodiment is:

[0073] Portland cement 30%

[0074] Quartz sand 36%

[0075] Filler 16%

[0076] Calcium Ionic Compound 4%

[0077] Crystal Precipitant 4%

[0078] Complexing Aid 3%

[0079] Coalescent 3%

[0080] Complexing agent 1.6%

[0081] Polycarboxylate superplasticizer 2.0%

[0082] Methylcellulose 0.4%

[0083] The filler is silica fume, the calcium ion compound is calcium hydroxide, the crystal precipitant is nano-scale sodium silicate, the complexing aid is aluminum stearate, the film-forming aid is polyvinyl acetate adhesive, and the complexing agent is Polyacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com