Integrated high-accuracy triaxial magnetic sensor

A high-precision, three-axis magnetic technology, applied in the field of weak signal sensing, can solve the problems of low resolution, high difficulty, limited resolution, etc., and achieve the effect of simple overall structure, reduced production cost, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

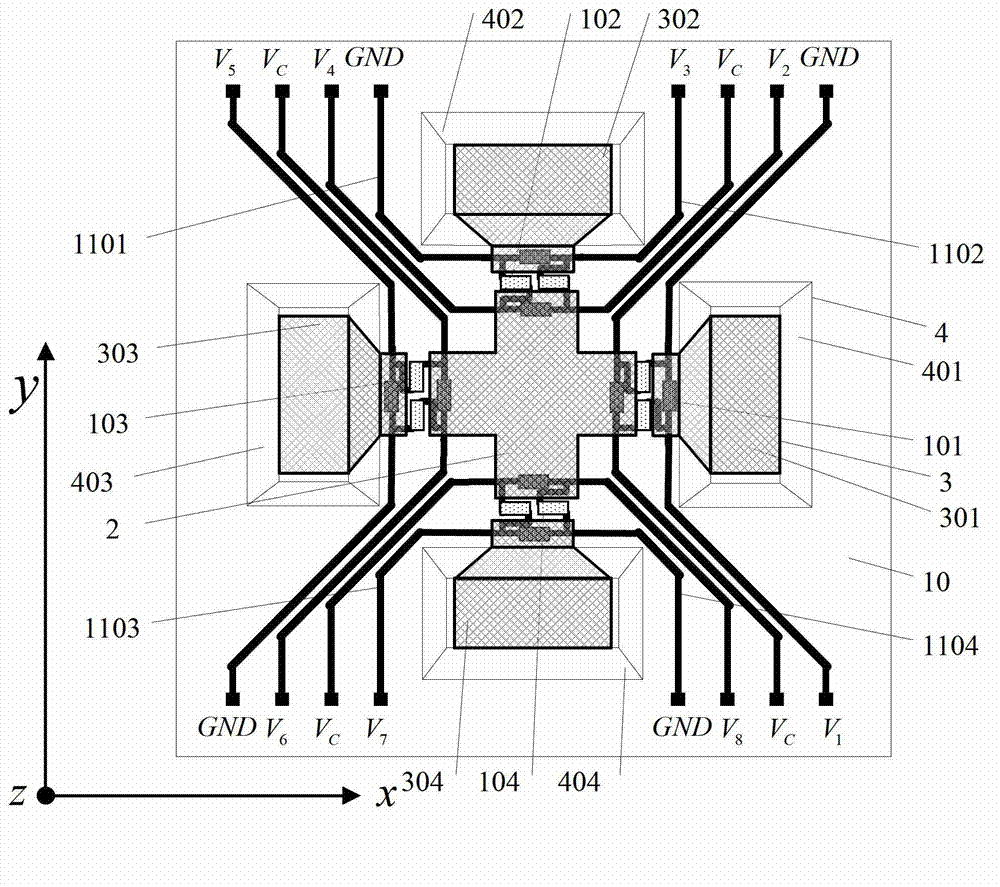

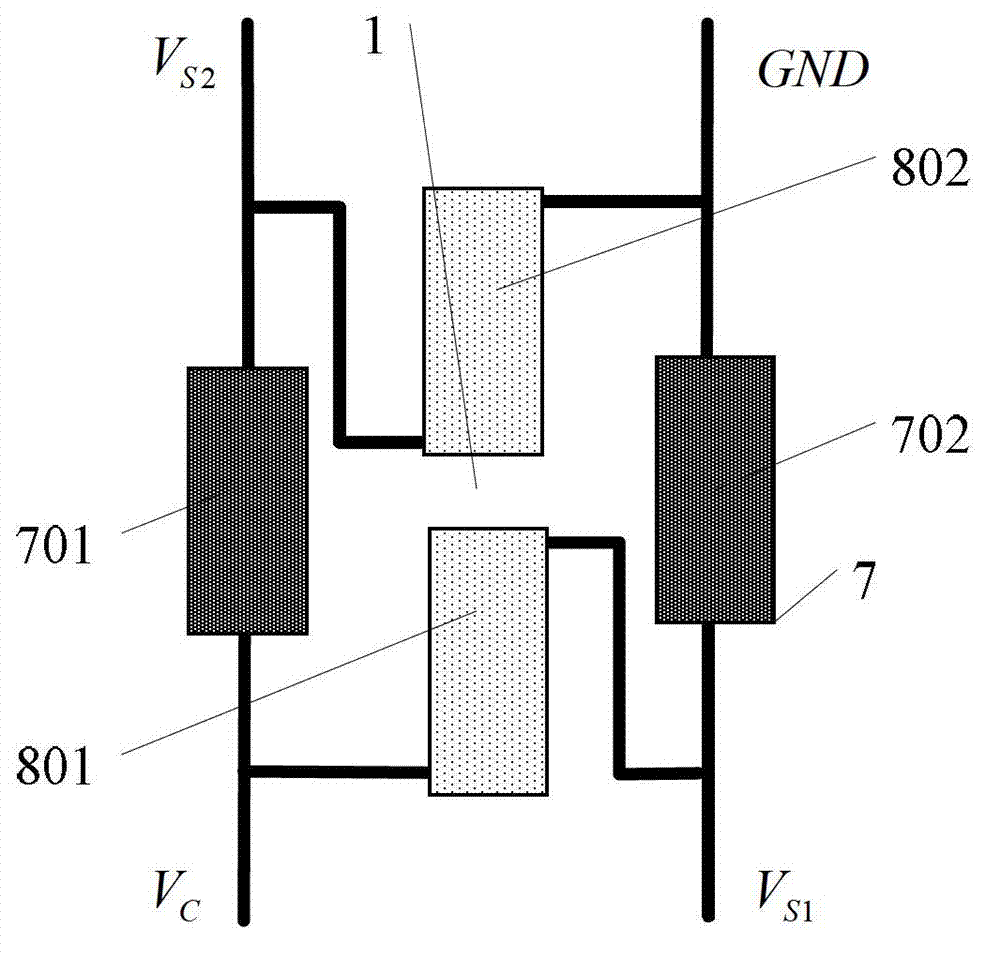

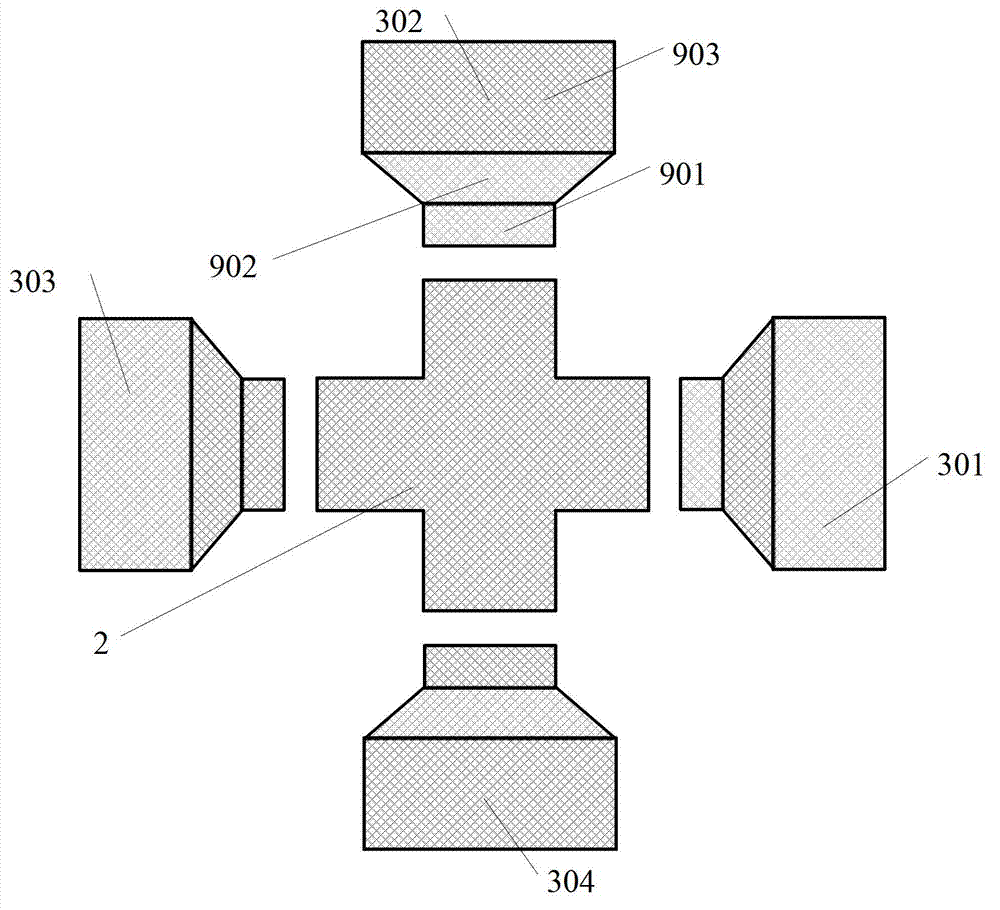

[0025] Such as figure 1 As shown, the integrated high-precision three-axis magnetic sensor of the present invention includes four magnetic measurement units 1, signal output and bias electrodes, a plane concentrator 2, four magnetic track concentrators 3, four pits 4, The base 10 and four sets of electrodes, the planar concentrator 2 adopts its own symmetrical structure, and is located in the middle of the base 10, and the four magnetic track concentrators 3 are distributed symmetrically on the four sides of the planar concentrator 2, and together form a magnetic flux transformer. The effect of rail and gathering amplification, each magnetic track collector 3 is located in a pit 4. The four magnetic measurement units 1 are respectively the first magnetic measurement unit 101, the second magnetic measurement unit 102, the third magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com