Construction method of dewatering well under foundation slab in foundation pit

A foundation base plate and construction method technology, applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problem of increasing the depth of precipitation well layout, precipitation time and precipitation range, and waterproof effect. To achieve the effect of convenient construction, increased adverse effects, and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A construction method for a foundation floor drop well in a foundation pit, comprising the following steps:

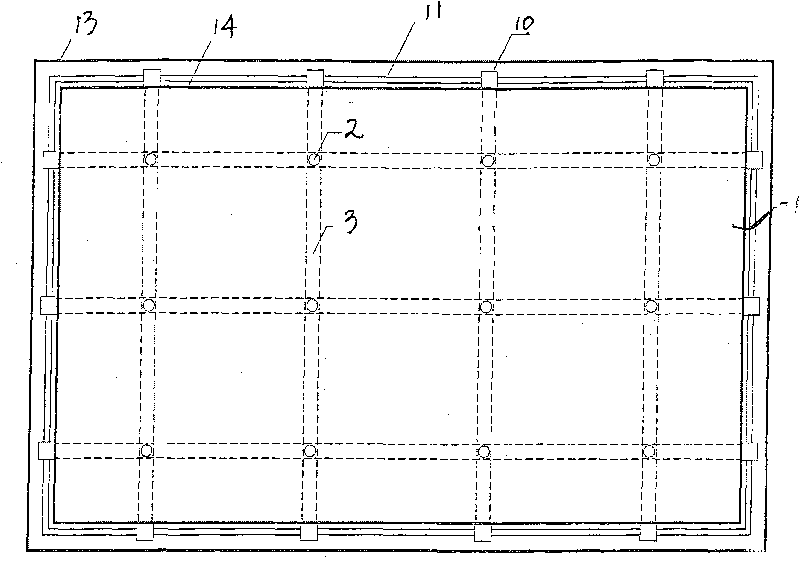

[0022] 1) Dewatering wells 2 are arranged in the foundation pit 1;

[0023] 2) During the excavation of the foundation pit, the dewatering well is not damaged to ensure the effectiveness of the dewatering well;

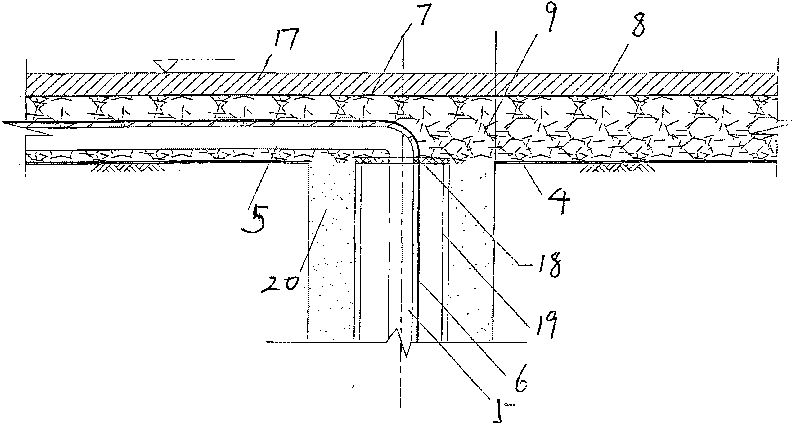

[0024] 3) After excavating the earthwork of the foundation pit to the base, excavate criss-cross trenches 3 along the center line of the dewatering well, and lay water-filtering geotextiles 4 in the trenches; Lay it in the trench and connect it to the outside of the pit, check the depth of the dewatering well, the pump and its pipeline to ensure its integrity and reliability; then lay granular gravel or pebbles 7 in the trench, and cover it with linoleum 8 to form a blind ditch 9. The blind ditch is connected to the side sump 10 of the foundation pit, and the drainage ditch 11 is arranged around the foundation pit;

[0025] 4) The underlayment and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com