Basement water drainage system

a drainage system and basement technology, applied in the direction of foundation engineering, artificial islands, special buildings, etc., can solve the problems of not being able to adapt to varying construction conditions, not being able to prevent the occurrence of condensation on the peripheral edges of cement floors, and being relatively expensive to manufacture, so as to achieve less complicated and less expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

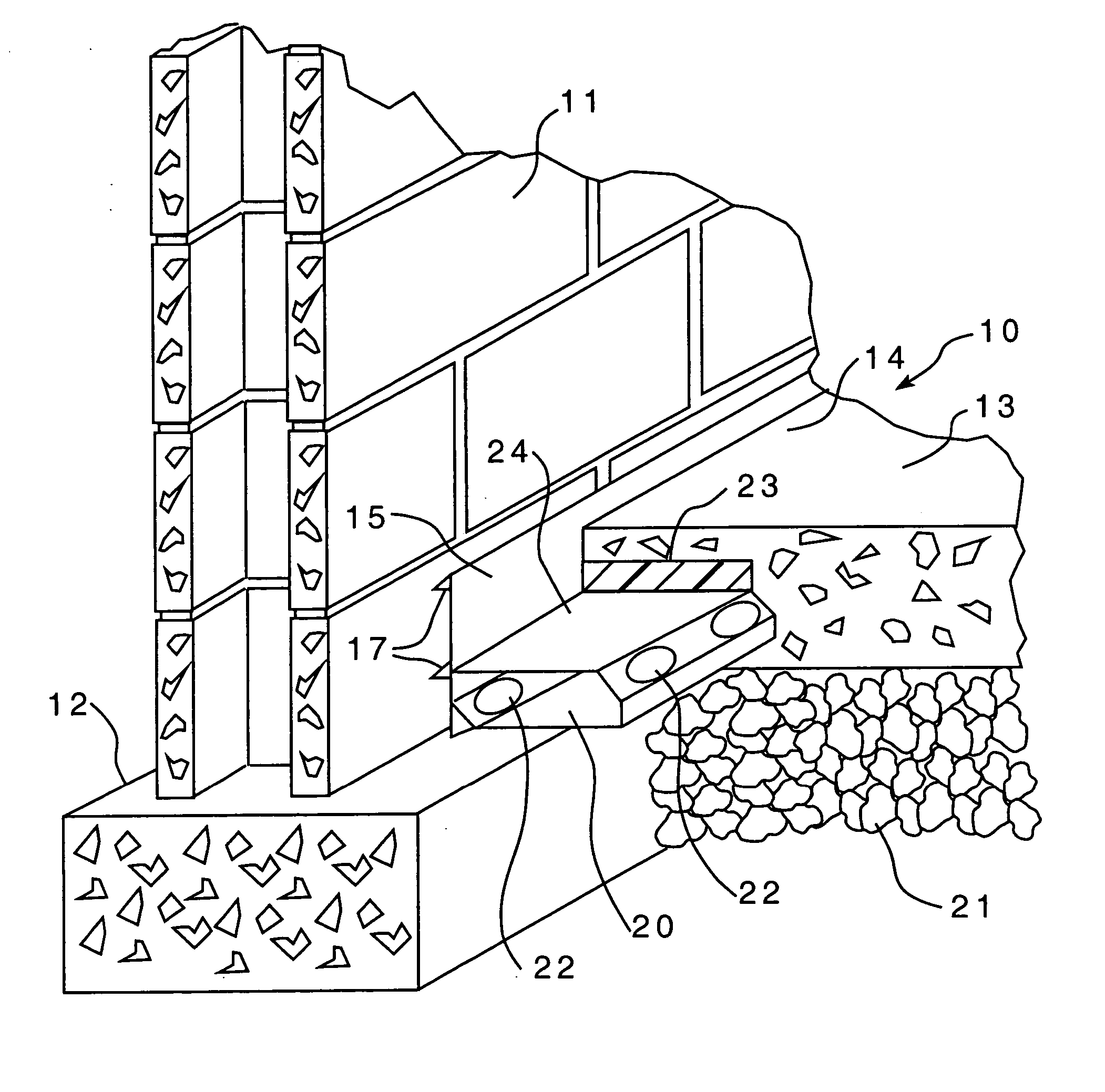

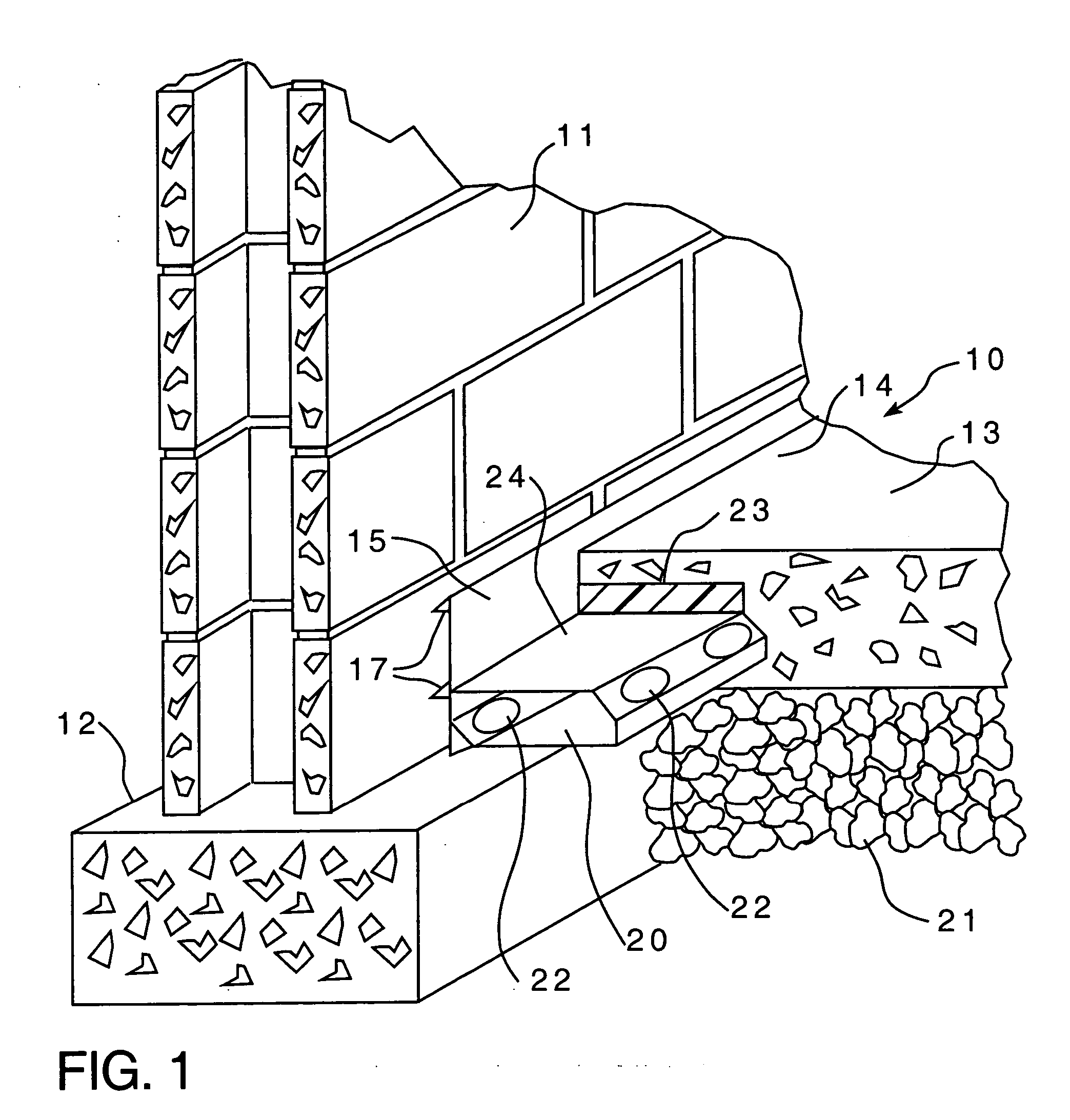

[0017] Referring to FIG. 1, the two-piece ground water drainage conduit system 10 of the present invention is provided for an interior subterranean wall 11 supported on footing 12 and further having a concrete floor 13 with a peripheral edge 14 supported on the footing 12.

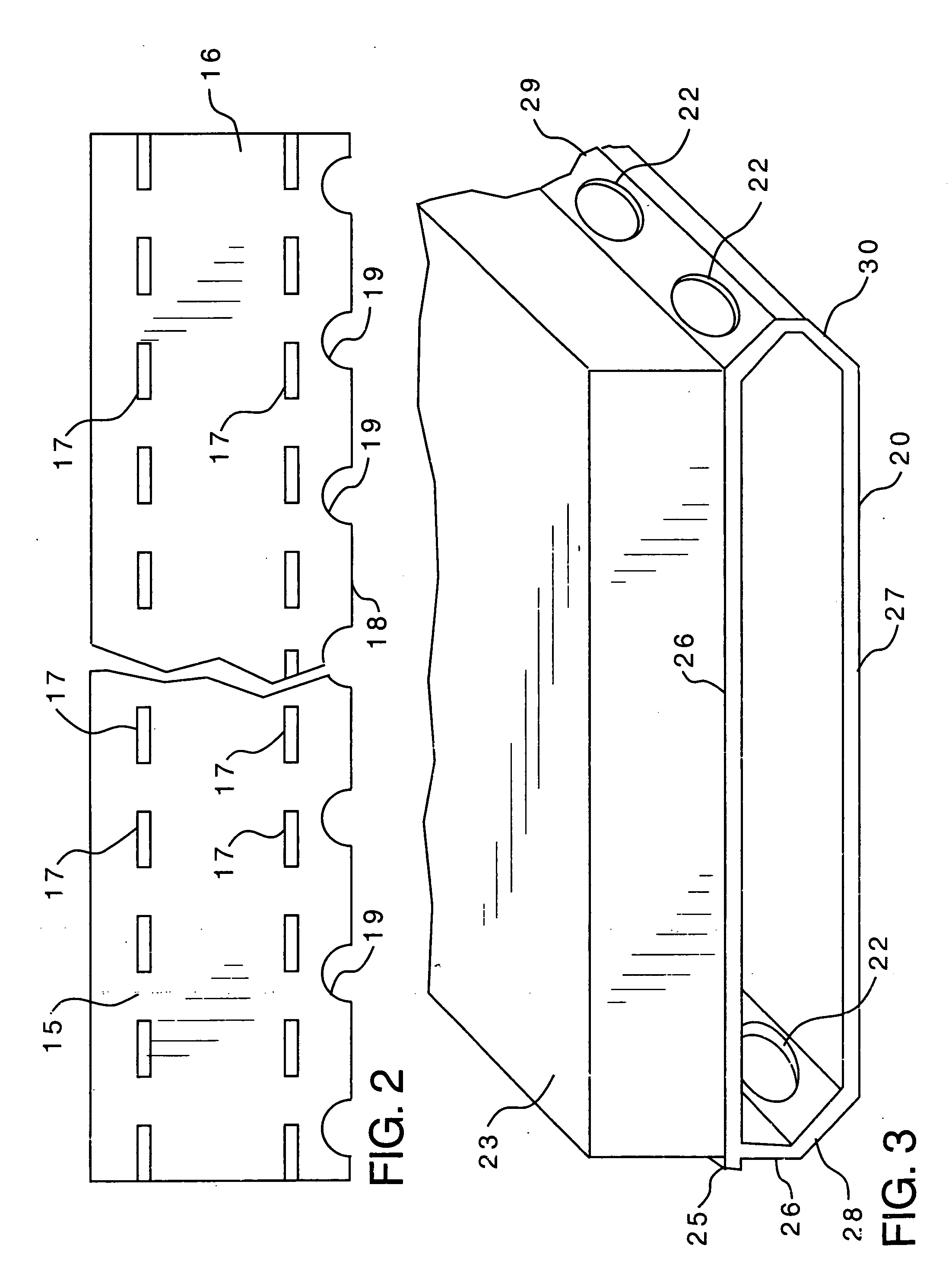

[0018] The two-piece conduit system of the present invention is comprised of a vertical wall portion 15 which extends horizontally and is disposed between the wall 11 and the floor 13. The rear surface 16 (see FIG. 2) of vertical wall portion 15 is provided with spacer protrusions 17 for engagement with the wall 11 whereby a narrow drainage passage is provided therebetween. The height of vertical wall portion 15 is dimensioned such that it extends above the floor 13. In this embodiment, the vertical wall portion 15 rests directly on top of footing 12 and the bottom edge 19 of vertical wall portion 15 is provided with spaced apertures 19 for passing ground water.

[0019] The second piece of the drainage conduit syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com