Arbitrary dip angle jointed rock sample coring chassis adjusting device

A technology of adjusting device and jointed rock, which is applied in sampling device and other directions, can solve the problems of drilling rock samples with different joint angles without consideration, difficulty in accurately simulating bedding rock mass, difficulty in similarity ratio, etc., and achieves convenient and reliable operation. , High drilling accuracy, simple instrument production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

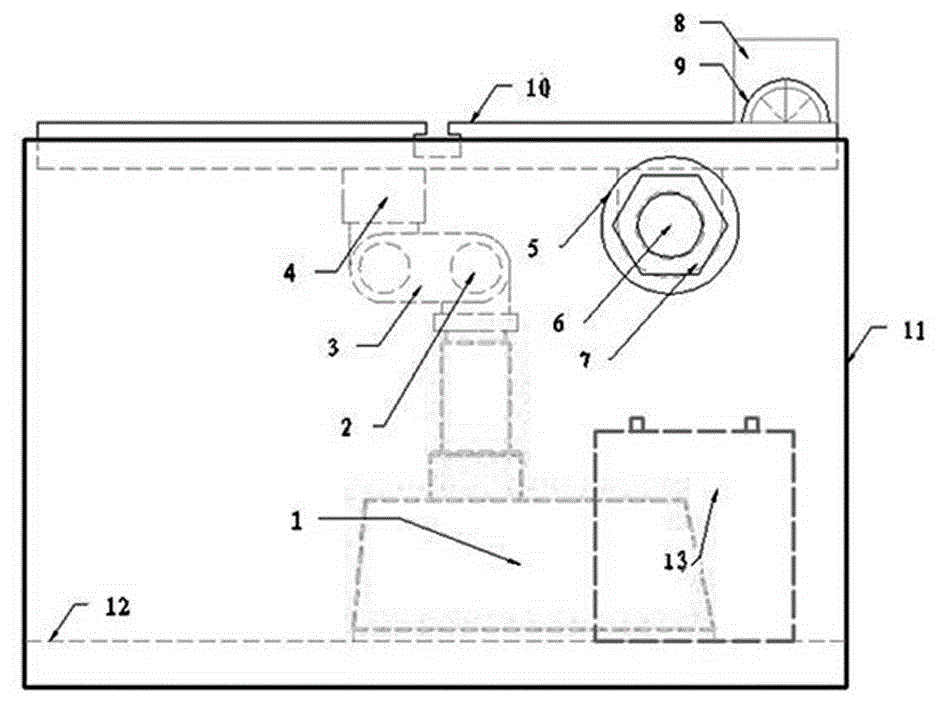

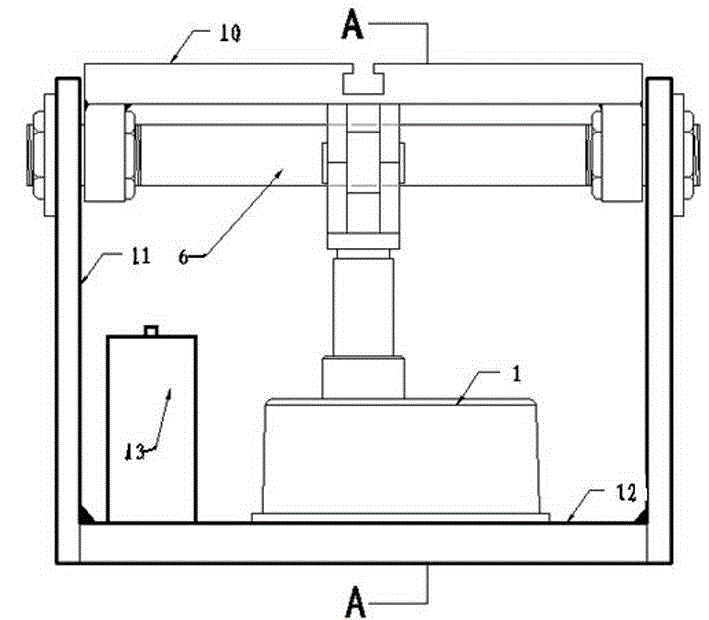

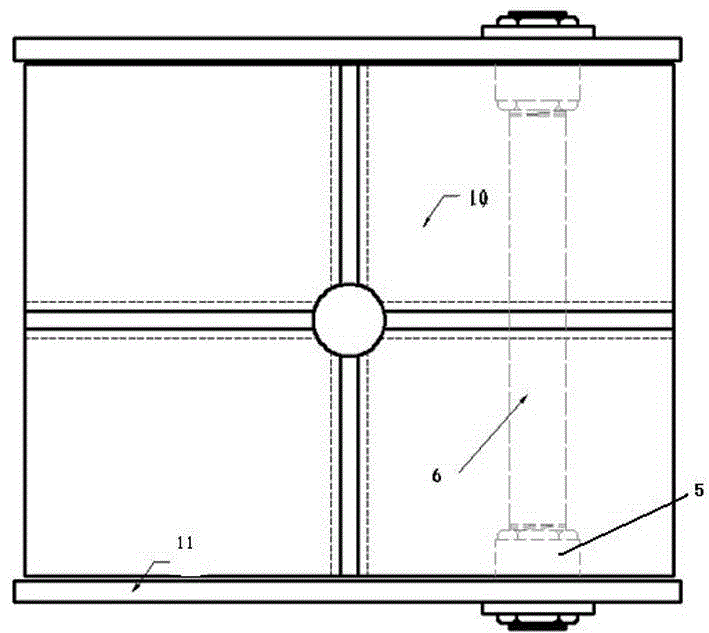

[0018] See attached Figure 1-6 As shown, a chassis adjustment device for coring jointed rock samples with any inclination angle includes a base 12, vertical steel plates 11 are arranged on both sides of the base, an automatic lifting hydraulic jack 1 is arranged on the base, and the automatic lifting hydraulic jack is connected by a shaft pin 2 There is a coupling plate 3, the coupling plate is connected with the coupling support 4 through the shaft pin 2, the top of the coupling support is provided with a steel plate tray 10 with a fixed convex groove, and the vertical steel plates on both sides of the base are set through the shaft sleeve 5. There are rigid cross braces 6, and the two ends of the rigid cross braces are locked by lock nuts 7, and a protractor 9 and a rock fixing device 14 are arranged on the steel plate tray.

[0019] Preferably, the automatic lifting hydraulic jack is connected with a battery 13 and a controller 15, and the movement of the automatic lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com