Thin wall non-corrodible steel sharp corner square, rectangular pipe and its production facility

A production equipment, stainless steel technology, applied in the direction of mechanical equipment, metal processing equipment, pipes, etc., can solve the problems of difficult adjustment, low positioning accuracy, low positioning accuracy of shaft sleeves, etc., achieve good interchangeability, improve positioning accuracy, and effective Facilitate the effect of operation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

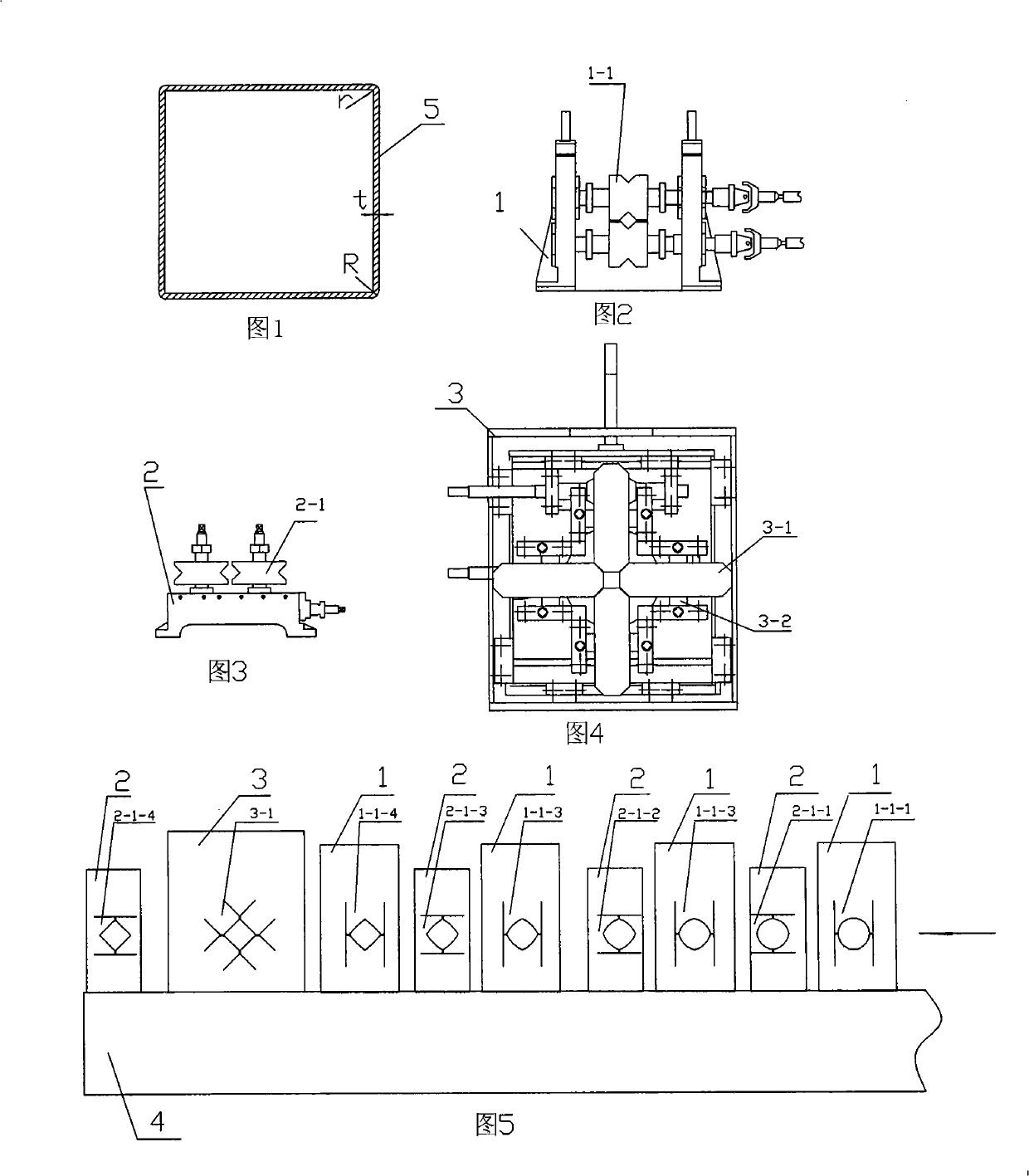

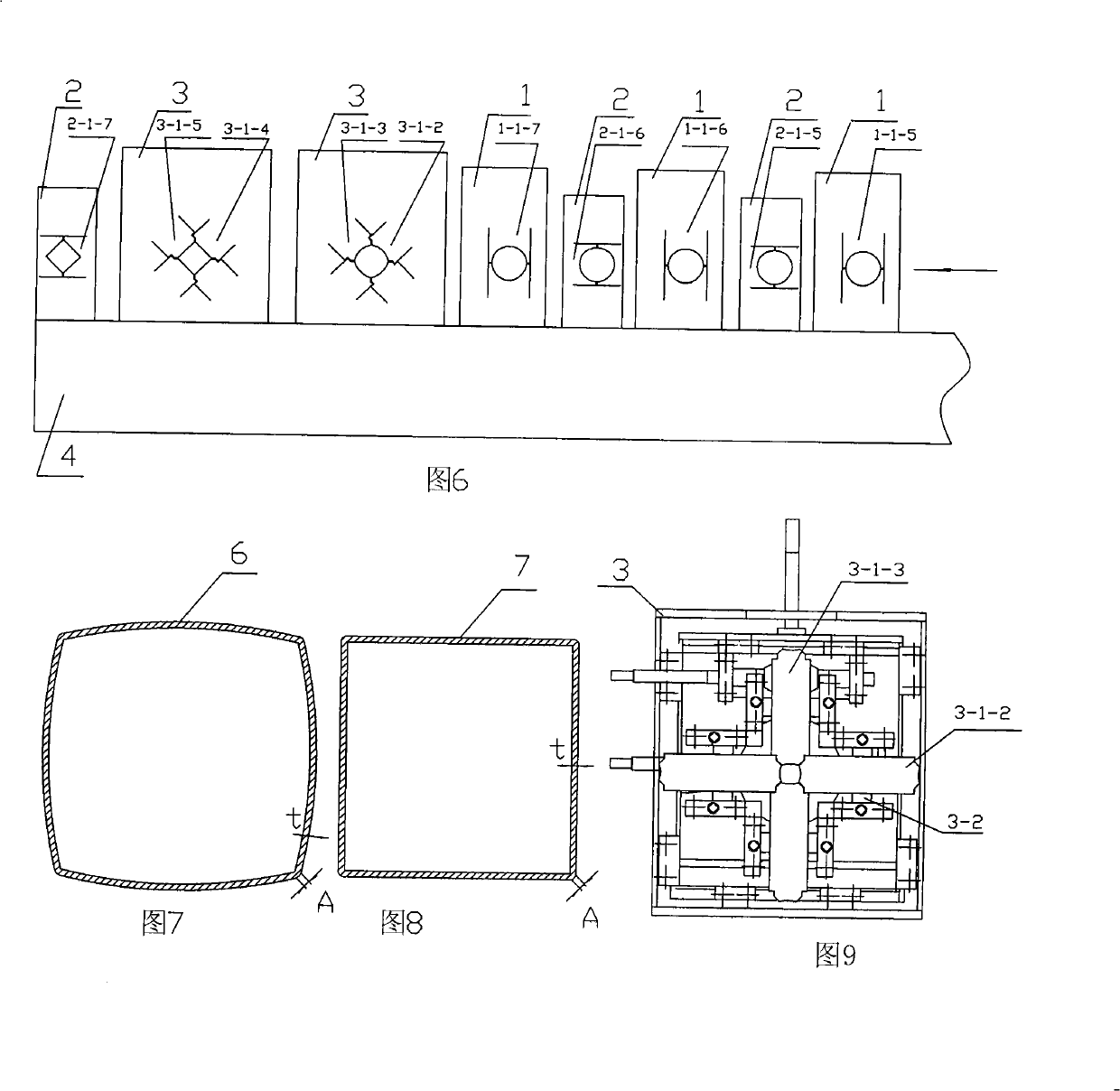

[0027] A thin-walled stainless steel sharp-angled square and rectangular tube 7 has a cross-sectional shape as shown in FIG. 8 . The distance between two mutually parallel intersection lines obtained by intersecting two adjacent planes of the square and rectangular tube with the arc surface located between these two planes A 2 t , Where t is the wall thickness of the square or rectangular tube. The above-mentioned square and rectangular tubes are exactly the thin-walled stainless steel sharp corner square and rectangular tubes claimed in the present invention.

Embodiment 2

[0029] Referring to Fig. 6, a kind of production equipment for manufacturing thin-walled stainless steel sharp corner square and rectangular tube 7 is arranged in sequence and is composed of the following racks and installed on the box body 4: the first flat roll rack 1, the second rack Vertical roll frame 2, third flat roll frame 1, fourth vertical roll frame 2, fifth flat roll frame 1, sixth turkey head frame 3, seventh turkey head frame 3 , The eighth vertical roller frame 2. The flat rolls 1-1-5 installed in the first flat roll frame 1, the vertical rolls 2-1-5 installed in the second vertical roll frame 2, and the flat rolls installed in the third flat roll frame 1 Roller 1-1-6, the vertical roll 2-1-6 that the 4th road vertical roll frame 2 adorns, the flat roll 1-1-7 that the fifth road flat roll 1 is adorned all are round hole type. The main function of the first to fifth racks is to generate forward force on the rolled pipe so that the rolled pipe has enough power to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com