Manufacturing method of stainless steel square pipe

A manufacturing method and technology of stainless steel pipes, which are applied in the field of steel material forming, can solve the problems of corrosion resistance and adverse effects of external dimensions, high process costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Processing step of the present invention is:

[0083] Tube blank → hot extrusion → cold processing → solution annealing heat treatment in protective atmosphere → cleaning → penetration inspection → ultrasonic inspection → visual and dimensional inspection → packaging.

[0084] The stainless steel that the present invention adopts, its component mass fraction is

[0085] C:≤0.065;

[0086] Mn: ≤2.00;

[0087] P: ≤0.035;

[0088] S: ≤0.005;

[0089] Si: ≤1.00;

[0090] Ni: 8.00-10.50;

[0091] Cr: 18.00-20.00;

[0092] Co:≤0.05;

[0093] Example 1

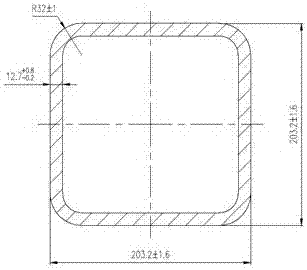

[0094] The finished product size is 203×203×12.7mm. Using hot extrusion + cold deformation process, using Φ450mm forged round ingot, extruded into Φ325×24mm round tube, cold rolled to get Φ264×14mm round tube, cold drawn to get 220×220×14mm square tube, cold drawn to get 203×203 ×12.7mm square tube. After solid solution annealing heat treatment in protective atmosphere, cleaning, penetration test, ultrasonic test, v...

Embodiment 2

[0096] The finished product size is 220×220×12mm. Using hot extrusion + cold deformation process, using Φ450mm forged round ingot, extruded into Φ325×18mm round tube, cold rolled to get Φ325×14mm round tube, cold drawn to get 236×236×14mm square tube, cold drawn to get 220×220 ×12mm square tube. After solid solution annealing heat treatment in protective atmosphere, cleaning, penetration test, ultrasonic test, visual and dimensional test, the finished product is obtained.

Embodiment 3

[0098]The finished product size is 250×250×15mm. Adopt hot extrusion + cold deformation process, use Φ450mm forged round ingot, extrude into Φ325×20mm round tube, cold draw to get Φ325×18mm round tube, cold draw to get 270×270×17mm square tube, cold draw to get 250×250 ×15mm square tube. After solid solution annealing heat treatment in protective atmosphere, cleaning, penetration test, ultrasonic test, visual and dimensional test, the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com