Processing method of small-curvature and small-angle bent pipe

A processing method and small-angle technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of long cycle, high cost, inability to process small-curvature and small-angle pipe bending, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The processing method of the small-curvature and small-angle elbow in the present embodiment is to carry out as follows:

[0021] 1. Replace the arc section with shrimp tubes in each straight section, and take materials from the bent pipe 1 section to be each straight section;

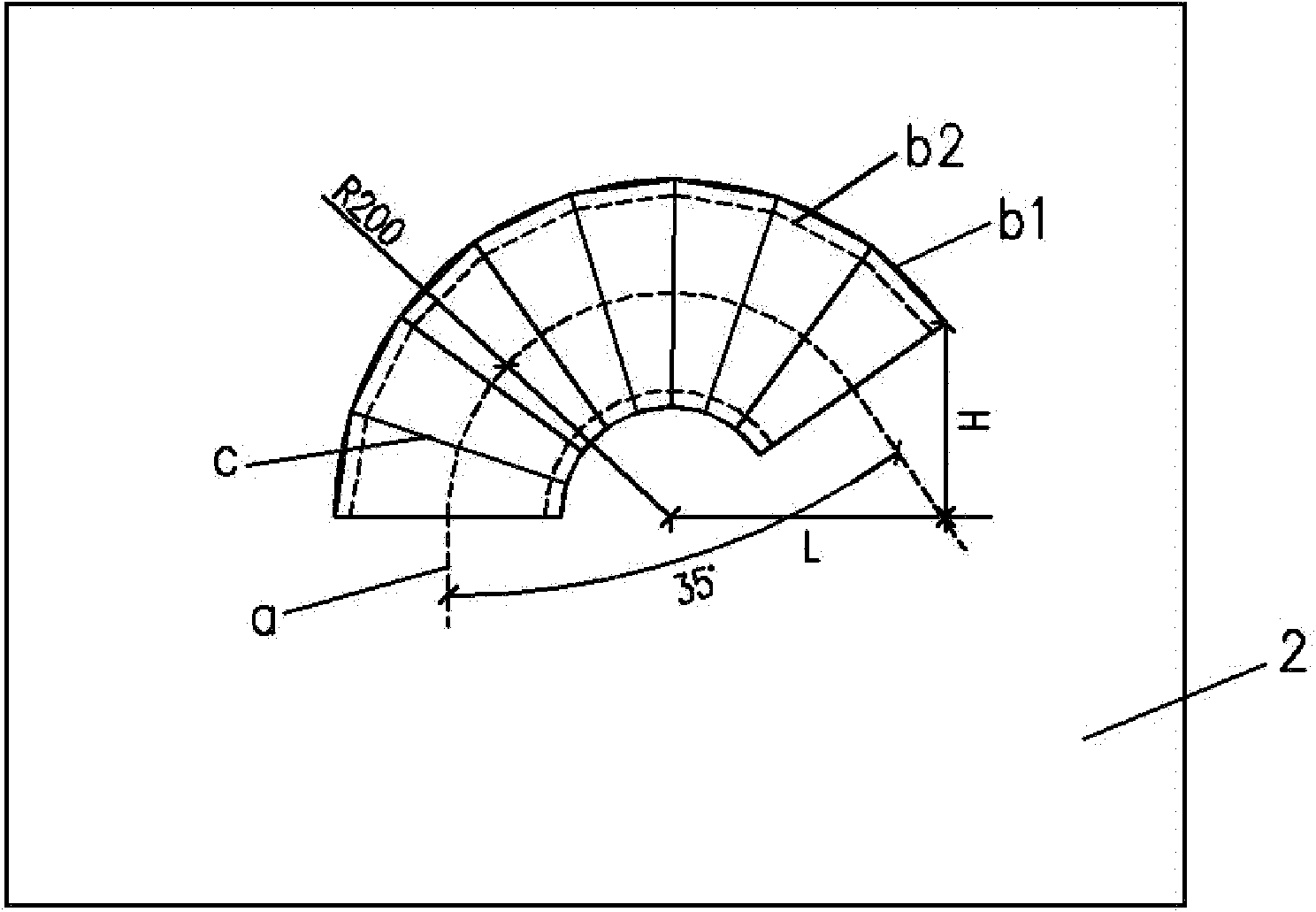

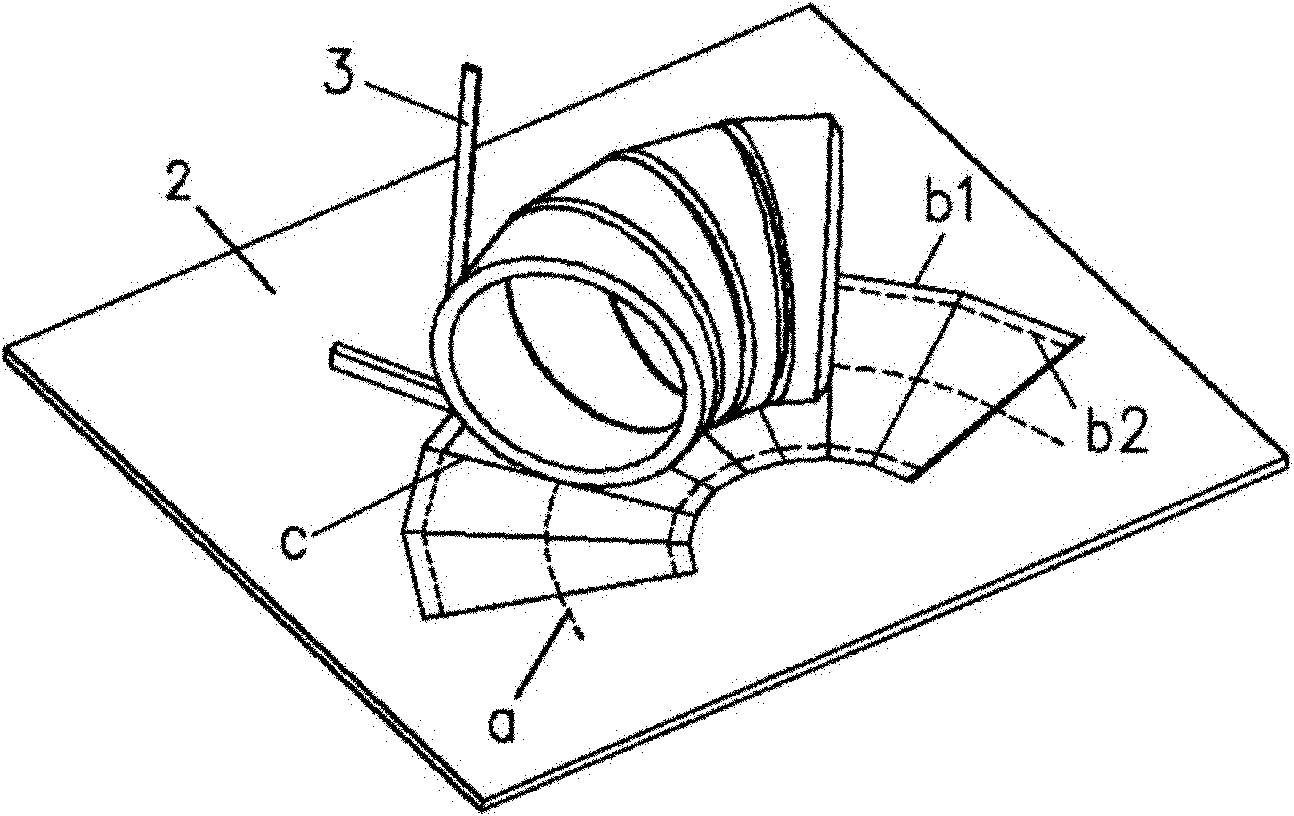

[0022] b. For each straight pipe section, cut off a 2mm length at the left end as an assembly gap, and form a flat end at the left end; cut and form a 35° peripheral groove at the right end of each straight section;

[0023] c. If figure 2 As shown, on the steel plate platform 2, the projected center line a, the outer contour line b1, the inner contour line b2 and the port line c of each straight pipe section for assembling the bent pipe are marked according to the workpiece to be processed; specifically, on the steel plate platform The mark on the line is, first draw the line according to the arc, and then mark each straight line segment according to the equal division point; figure 2 The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com