Perpendicularity checking device for roller stand angle square positioning gauge of spinning machine

A technology of calibration device and roller seat, which is applied in the direction of adopting mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems of the quality of equipment flat cars, the inability to detect or calibrate, and the easy wear of the square edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The device for verifying the verticality of the bezel of the ring frame of the spinning frame according to the present invention will be further described in detail in conjunction with the accompanying drawings.

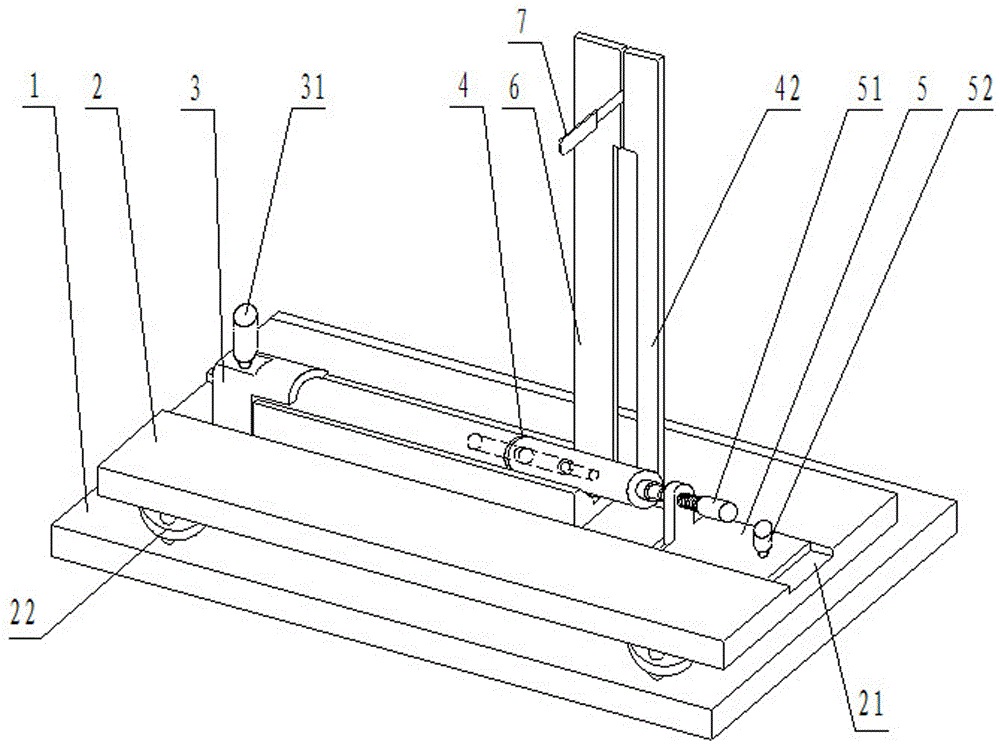

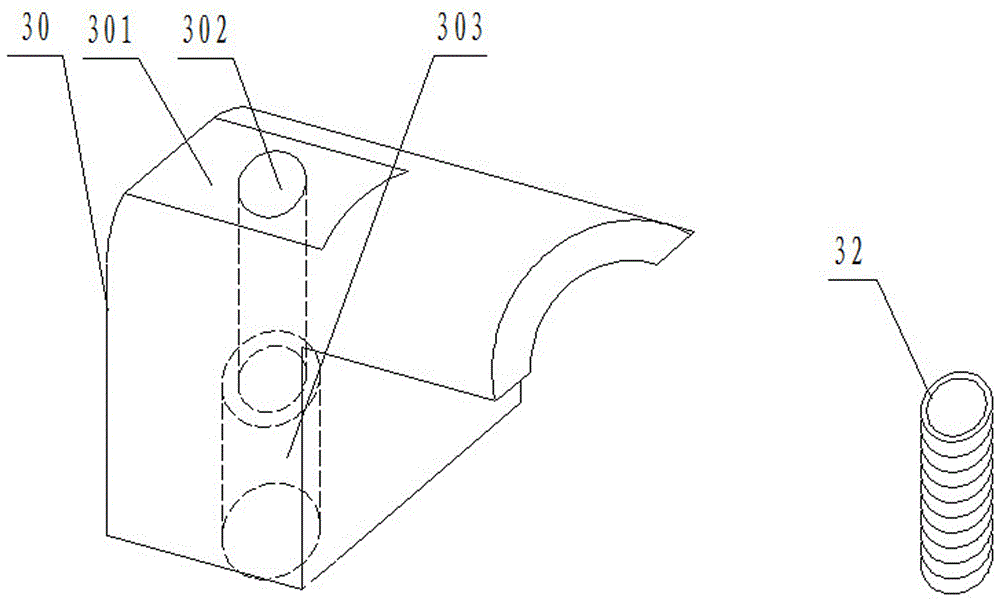

[0019] Depend on Figure 1 to Figure 6 It can be seen that the device for verifying the verticality of the roller seat square gauge of the spinning frame in this embodiment includes a base 1 , a detection plate 2 , a left positioning assembly 3 , a detection assembly 4 , a right positioning assembly 5 and a roller seat square gauge 6 .

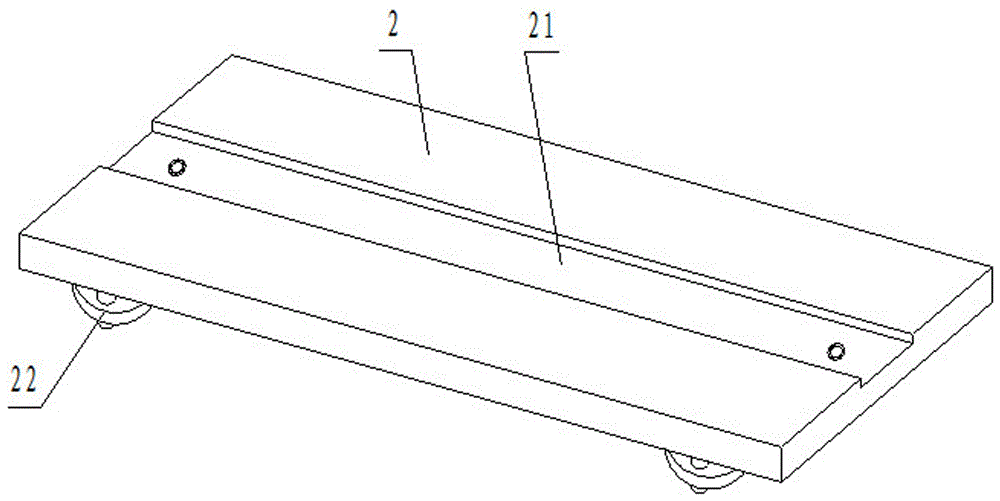

[0020] In this embodiment, by figure 1 , figure 2 It can be seen that the detection plate 2 is installed on the base 1, and leveling bolts 22 are respectively arranged at each corner between the detection plate 2 and the base 1. In this embodiment, four corners on the base 1 are provided with There are leveling bolts 22, and the level of the detection plate 2 is adjusted through the leveling bolts 22; a concave groove 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com