Liquid storage tank wall material and preparation method thereof

A liquid storage tank and tank wall technology, which is applied in the field of materials, can solve the problem that the material of the liquid storage tank cannot meet the requirements of various functional requirements inside and outside, and harsh requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

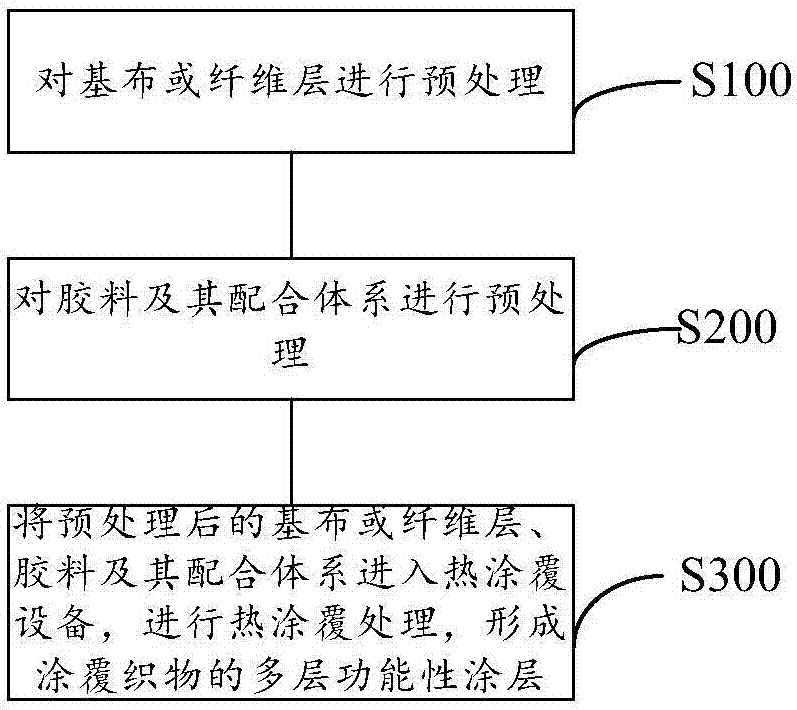

[0028] In the first aspect, based on the same inventive concept, the present application also provides a method for preparing the tank wall material of the liquid storage tank, please refer to figure 1 , the preparation method comprises:

[0029] Step S100, pretreat the base cloth or fiber layer.

[0030] Wherein, the pretreatment of the base fabric or the fiber layer in step S100 is specifically drying the base fabric or the fiber layer, and the drying temperature is 70°C-90°C, preferably 70°C, 75°C, 90°C. Fully remove the moisture contained in the fiber by pretreating the base cloth or fiber layer.

[0031] Step S200, performing pretreatment on the rubber material and its compounding system.

[0032] Wherein, in the step S200, the rubber material and its compounding system are pretreated, specifically, the rubber material and its compounding system are dehumidified. The moisture in the rubber material and its compound system is removed by pretreating the rubber compound a...

Embodiment 1

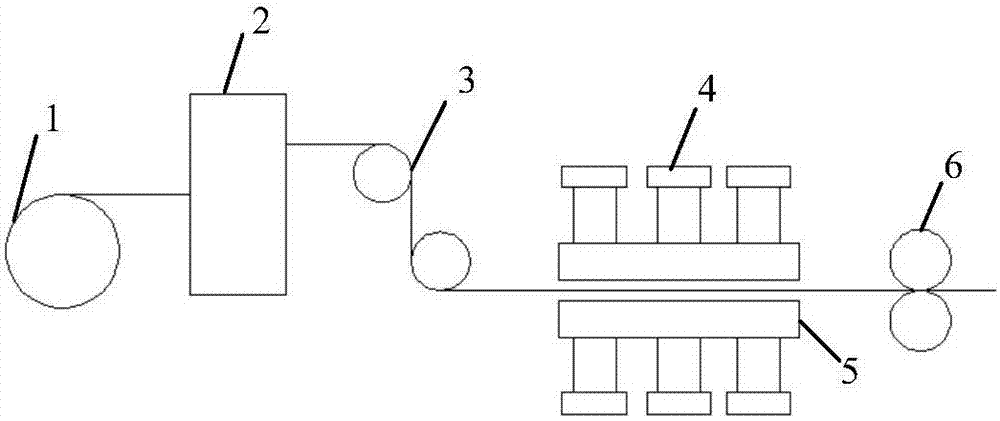

[0041] S1, the base cloth or the fiber layer 1 is dried in an oven 2, and the drying temperature is 70°C.

[0042] S2, dehumidify the rubber compound and its compound system through the dehumidifier 4, and the drying temperature for dehumidification is 65°C.

[0043] S3, using six extruders to simultaneously extrude the pretreated rubber compound and its matching system to feed two molds 5, and form a multi-layer function of coated fabric on the pretreated adhesive plaster or fiber layer 1 permanent coating.

[0044] S4, after the formed coated fabric passes through the calendering roller 6, it is put into storage after being cooled, weighed and coiled.

Embodiment 2

[0046] S1, the base cloth or the fiber layer 1 is dried in an oven 2, and the drying temperature is 72°C.

[0047] S2, dehumidify the rubber compound and its compound system through the dehumidifier 4, and the drying temperature for dehumidification is 68°C.

[0048] S3, using six extruders to simultaneously extrude the pretreated rubber compound and its matching system to feed two molds 5, and form a multi-layer function of coated fabric on the pretreated adhesive plaster or fiber layer 1 permanent coating.

[0049] S4, after the formed coated fabric passes through the calendering roller 6, it is put into storage after being cooled, weighed and coiled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com