Environment-friendly polyurethane curing agent and its preparation method and application

A polyurethane curing agent, environmentally friendly technology, used in polyurea/polyurethane coatings, organic chemistry, coatings, etc., can solve the problems of low free TDI content polyurethane curing agent, etc., to achieve easy industrial application, high NCO value, matting Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

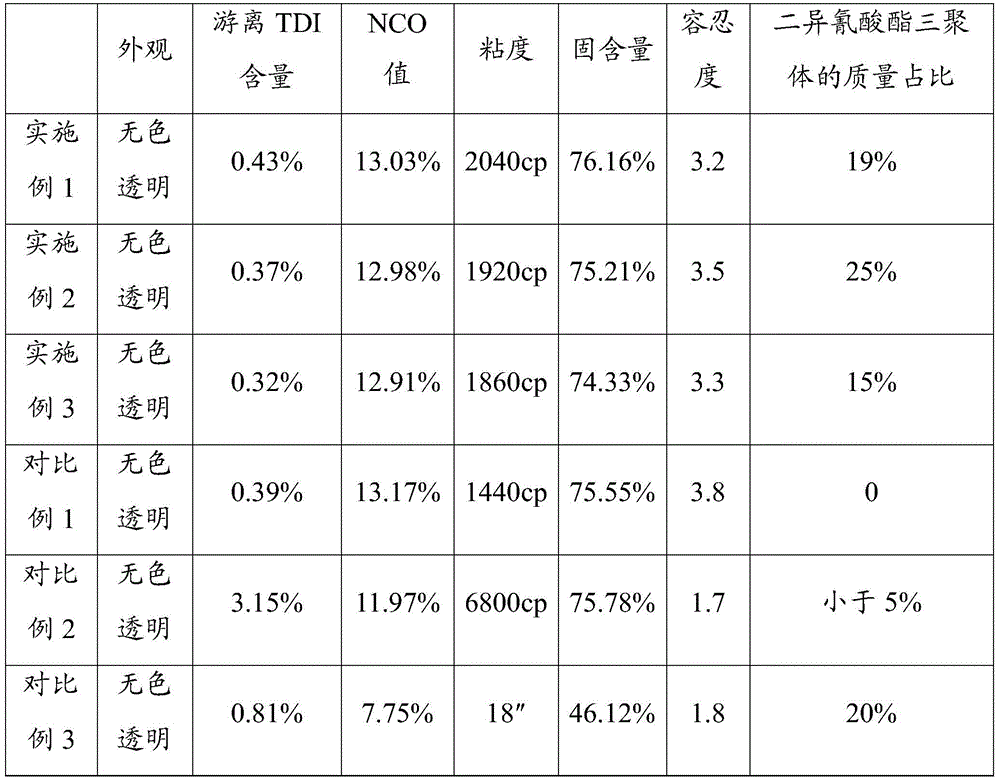

Examples

Embodiment 1

[0041] A. The mixed alcohol of 60kg trimethylolpropane and 20kg methylol propane is heated to 120 ℃ of dehydration 2 hours, stand-by, wherein, the mol ratio of methylol propanediol and trimethylol propane in the described mixed alcohol is 1: 2;

[0042]Under the protection of nitrogen, 213kg of butyl acetate and 2,4-toluene diisocyanate and 2,6-toluene diisocyanate (wherein the mass ratio of 2,4-toluene diisocyanate is 69%) 610kg into the reaction kettle Stir evenly and heat up to 42°C, then drop the dehydrated mixed alcohol into the reaction kettle for 1 hour, and keep the temperature between 66-78°C, the NCO group in the diisocyanate monomer The molar ratio of the group to the OH group in the mixed alcohol is 3.92~1;

[0043] After the dropwise addition is completed, after 1 hour of insulation at 70°C and 1 hour of insulation at 80°C, the mass of diisocyanate monomer in the gas chromatography measurement system is about 290kg, and 0.3kg of tris-(dimethylaminomethyl)phenol i...

Embodiment 2

[0046] A. Heat the mixed alcohol of 50kg trimethylolpropane and 21kg 1,4-butanediol to 120°C for dehydration for 1.5 hours, and set aside for use, wherein, in the mixed alcohol, 1,4-butanediol and trimethylol The molar ratio of propane is 1:1.6;

[0047] Under the protection of nitrogen, 195kg of propylene glycol methyl ether acetate and 2,4-toluene diisocyanate and 2,6-toluene diisocyanate (wherein, the mass ratio of 2,4-toluene diisocyanate is 73%) 530kg input Stir evenly in the reaction kettle and heat up to 50°C, then drop the dehydrated mixed alcohol into the reaction kettle for 1 hour and 10 minutes, and maintain the temperature between 65-81°C, the diisocyanate monomer The molar ratio of the NCO group in the mixed alcohol to the OH group in the mixed alcohol is 3.832:1;

[0048] After the dropwise addition, keep warm at 70°C for 1 hour, and keep warm at 80°C for 1 hour. After the heat preservation is completed, the mass of the diisocyanate monomer in the system is dete...

Embodiment 3

[0051] A. Heat 80kg of trimethylolpropane and 33kg of 1,3-propanediol to 150°C for dehydration for 2.5 hours, and set aside for use, wherein the molar ratio of 1,3-propanediol to trimethylolpropane in the mixed alcohol is 1 :1.4;

[0052] Under the protection of nitrogen, 300kg of n-propyl acetate and 2,4-toluene diisocyanate and 2,6-toluene diisocyanate (wherein the mass ratio of 2,4-toluene diisocyanate is 59%) 720kg into the reaction Stir evenly in the kettle and heat up to 65°C, then drop the dehydrated mixed alcohol into the reaction kettle for 1.5 hours, and maintain the temperature between 69 and 79°C, the NCO in the diisocyanate monomer The molar ratio of the group to the OH group in the mixed alcohol is 3.05:1;

[0053] After the dropwise addition, keep warm at 70°C for 1 hour, and keep warm at 80°C for 1 hour. After the heat preservation is completed, the mass of the diisocyanate monomer in the system is determined by gas chromatography to be about 260kg, and 0.45kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com