Composition for electric wire protective material, electric wire protective material, and wire harness

A technology for protecting materials and compositions, applied in the field of wire harnesses, to achieve good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

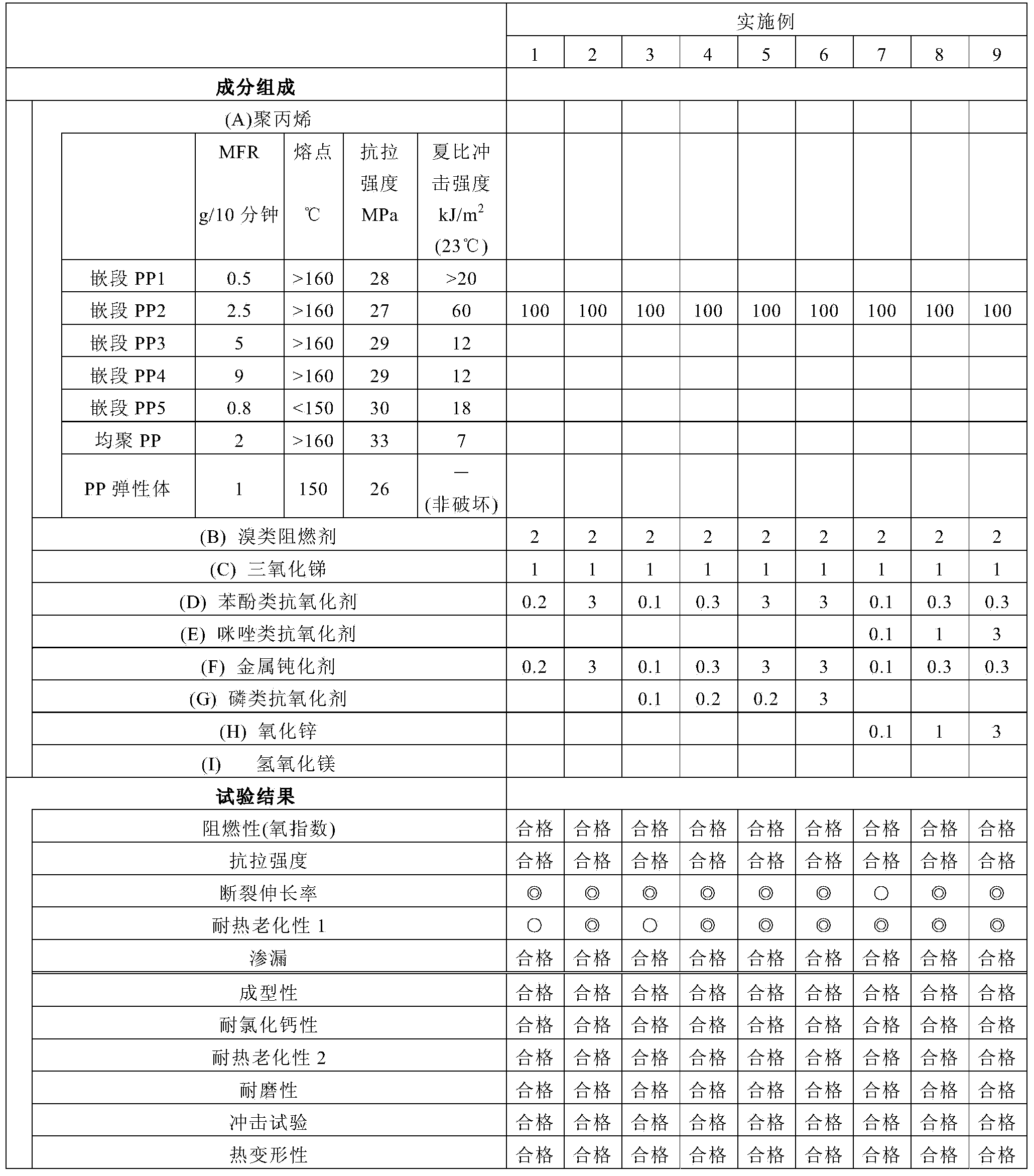

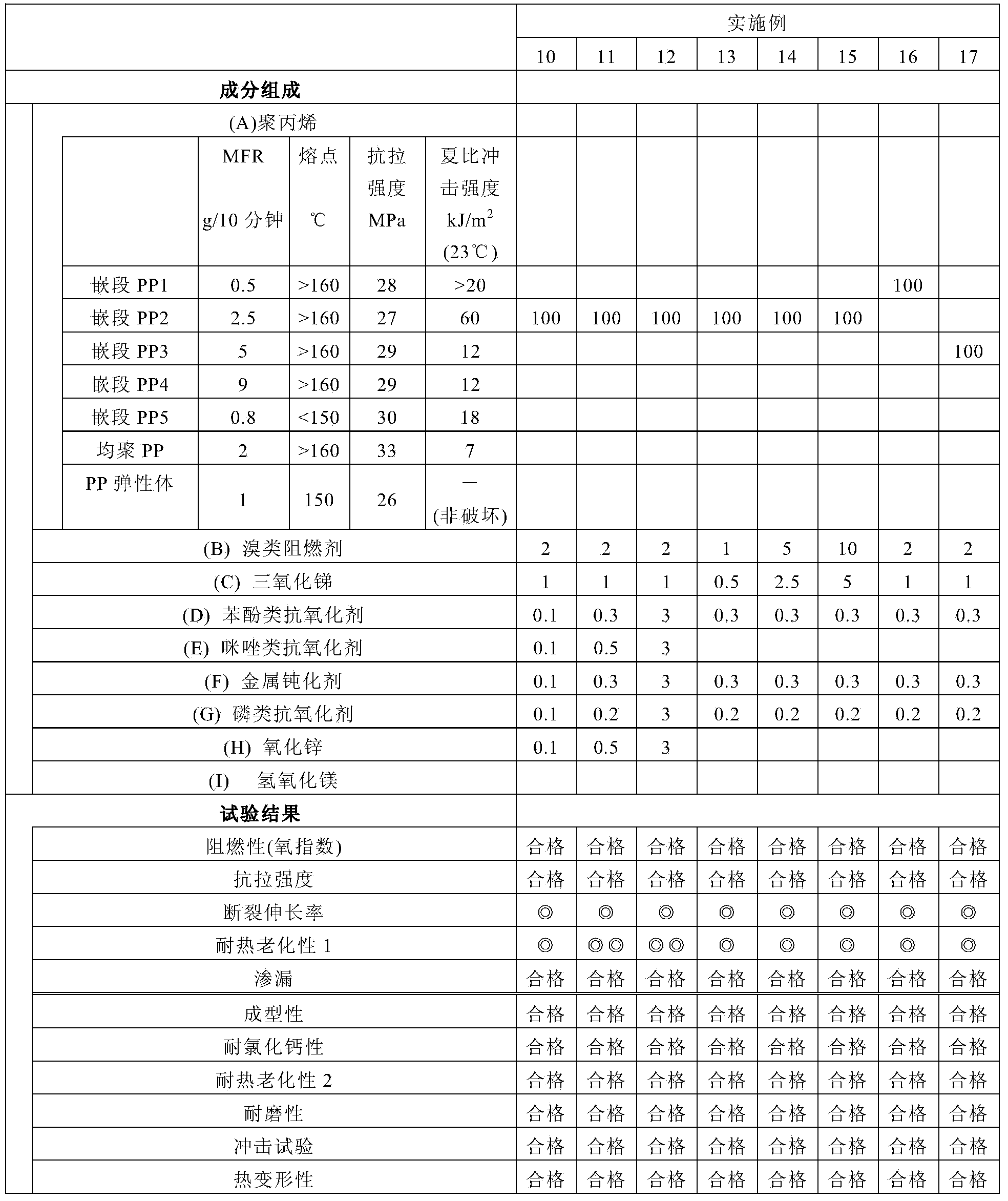

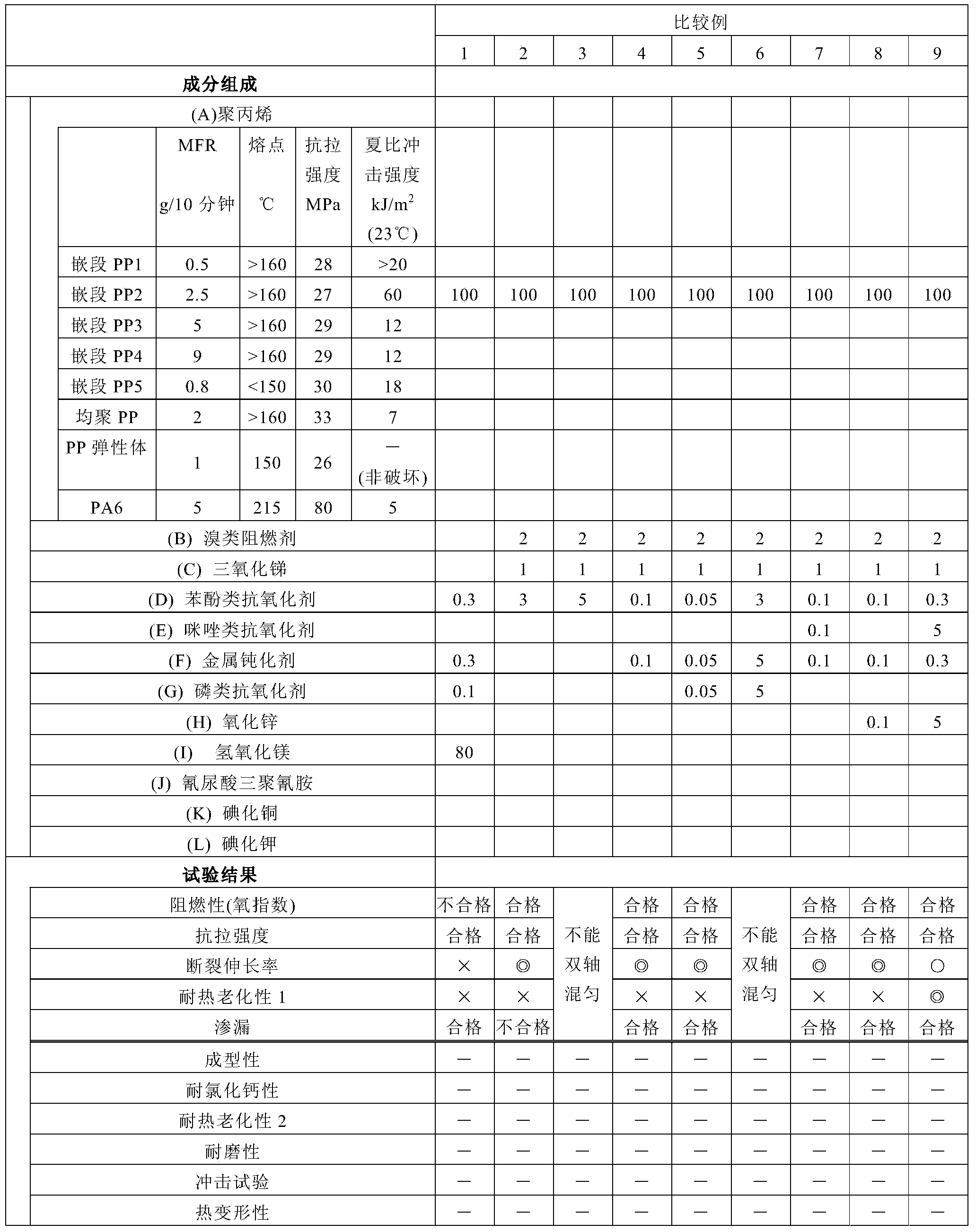

[0064] Examples and comparative examples of the present invention are shown below. In addition, the present invention is not limited to these examples.

[0065] [Test materials and manufacturers]

[0066] The test materials used in Examples and Comparative Examples are shown together with manufacturers, trade names, and the like. Regarding polypropylene, MFR, melting point, tensile strength, Charpy impact strength, etc. are shown in the table.

[0067] (A: Polypropylene)

[0068] [1] Block PP1: Japan Polypro Co., Ltd., trade name "EC9"

[0069] [2] Block PP2: made by Prime Polymer Co., Ltd., trade name "J356HP"

[0070] [3] Block PP3: made by Prime Polymer Co., Ltd., trade name "J704UG"

[0071] [4] Block PP4: Made by Prime Polymer Co., Ltd., trade name "J705UG"

[0072] [5] Block PP5: Japan Polypro Co., Ltd., trade name "EG8"

[0073] [6] Homopolymer PP: manufactured by Prime Polymer Co., Ltd., trade name "E203GP"

[0074] [7] PP elastomer: manufactured by Sumitomo Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com