Explosion-proof sentry box

An anti-explosion and sentry box technology, applied in the field of anti-explosion sentry boxes, can solve the problems of not having bulletproof, anti-explosion attack performance, casualties of military and police personnel, etc., and achieve the effect of protecting life and property safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the technical scheme of the present invention will be further described,

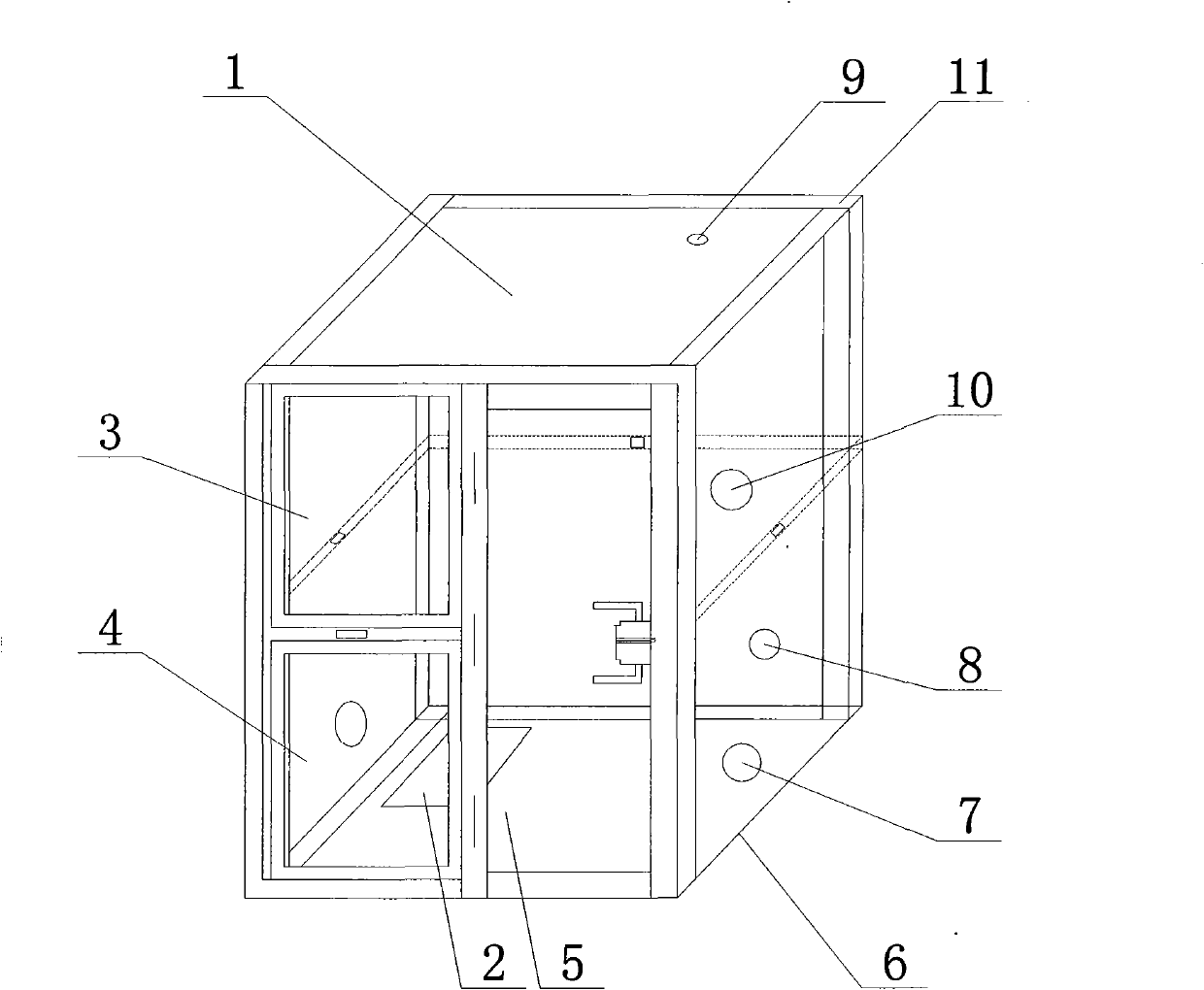

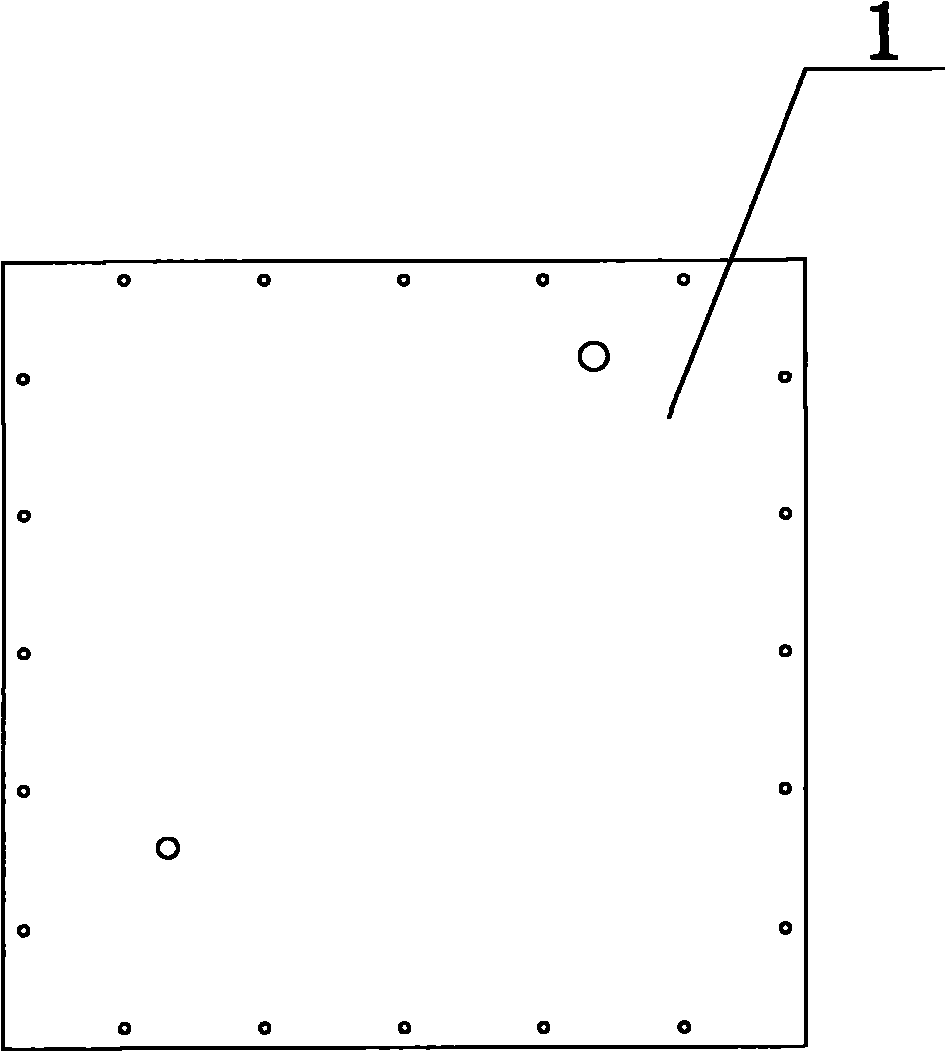

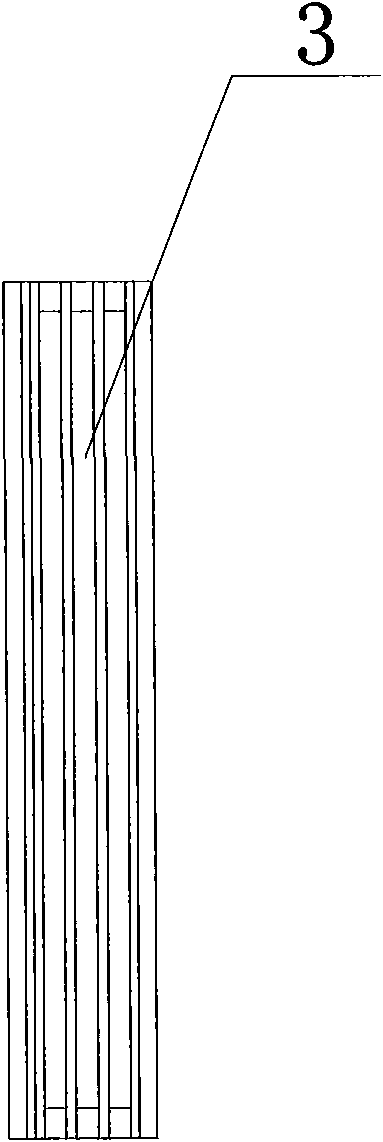

[0018] Depend on figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 It can be seen that the explosion-proof sentry box is composed of a skeleton 11, a top plate 1, an explosion-proof composite glass wall panel, an explosion-proof composite glass door 5, and a floor 6, wherein the skeleton 11 is welded by section steel, and a plurality of The screw hole connected with the top plate 1, the doorway and the hinge base connected with the explosion-proof composite glass door 5, the steel plane around the bonded explosion-proof composite glass wall panel and the screw hole connected with the floor 6, the top plate 1 is made of three layers of galvanized iron The plates are arranged in a parallel overlapping combination, and a certain distance is set between each corresponding plane in the top plate 1, so that a cavity structure is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com