Assembly tool and assembly process for screw bearing of automobile steering device

An automobile steering gear and bearing assembly technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of long time consumption, solid grease blocking the oil circuit, etc., to achieve simple structure, improve assembly time, Take out convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

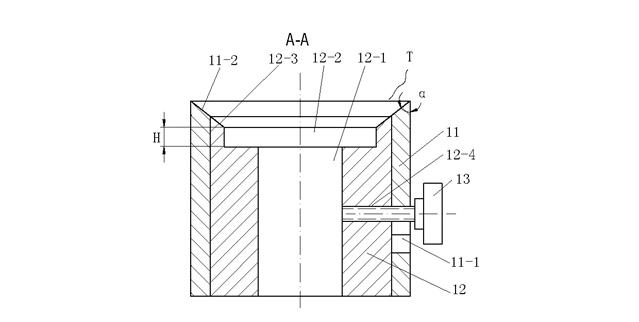

[0023] This assembly tool is used to install the screw bearing of the automobile steering gear, so the shape and size of the assembly tool must match the parts of the screw bearing of the automobile steering gear to be installed.

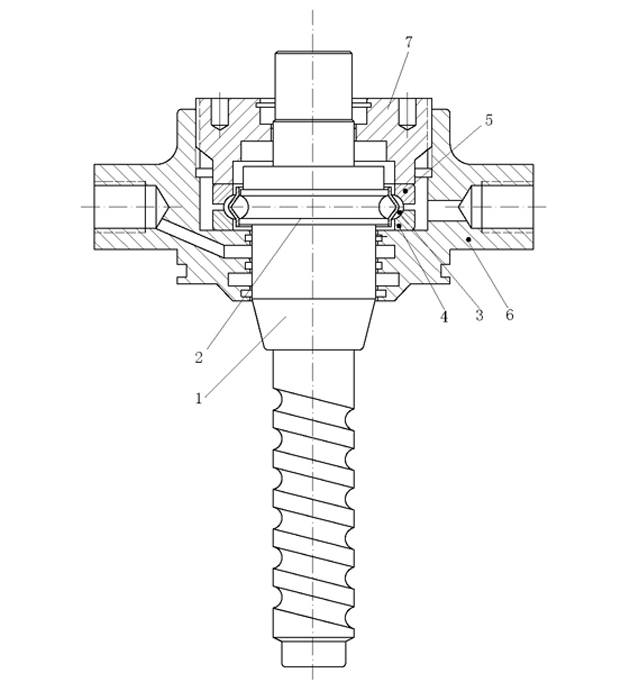

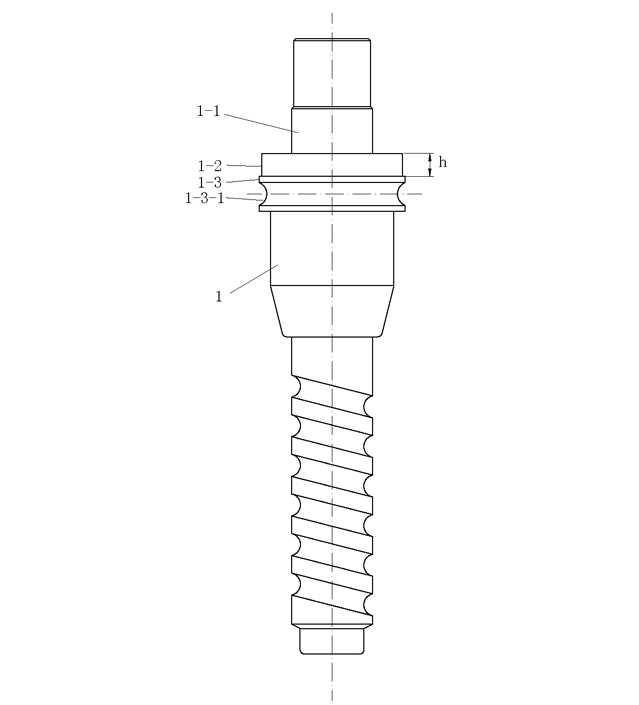

[0024] See Figure 1 to Figure 3 , The screw bearing of the automobile steering gear includes a screw 1, a cage 2, a steel ball 3, a lower screw ring 4, an upper screw ring 5, a front cover 6, and a screw plug 7. The head 1-1 of the screw 1 has a positioning ring body 1-2 and a steel ball placing ring body 1-3, the diameter of the positioning ring body 1-2 is slightly smaller than the steel ball placing ring body 1-3, the steel ball placing ring body 1-3 There is an arc groove 1-3-1 on the ball placement ring body 1-3, and the steel ball 3 is placed in the arc groove 1-3-1 of the steel ball placement ring body 1-3. The spaces are separated by the above-mentioned retainer 2 that fits on the screw 1. The front cover 6 has a through hole, the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com