Continuous casting bearing steel round steel and method for producing the same

A manufacturing method, bearing steel technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

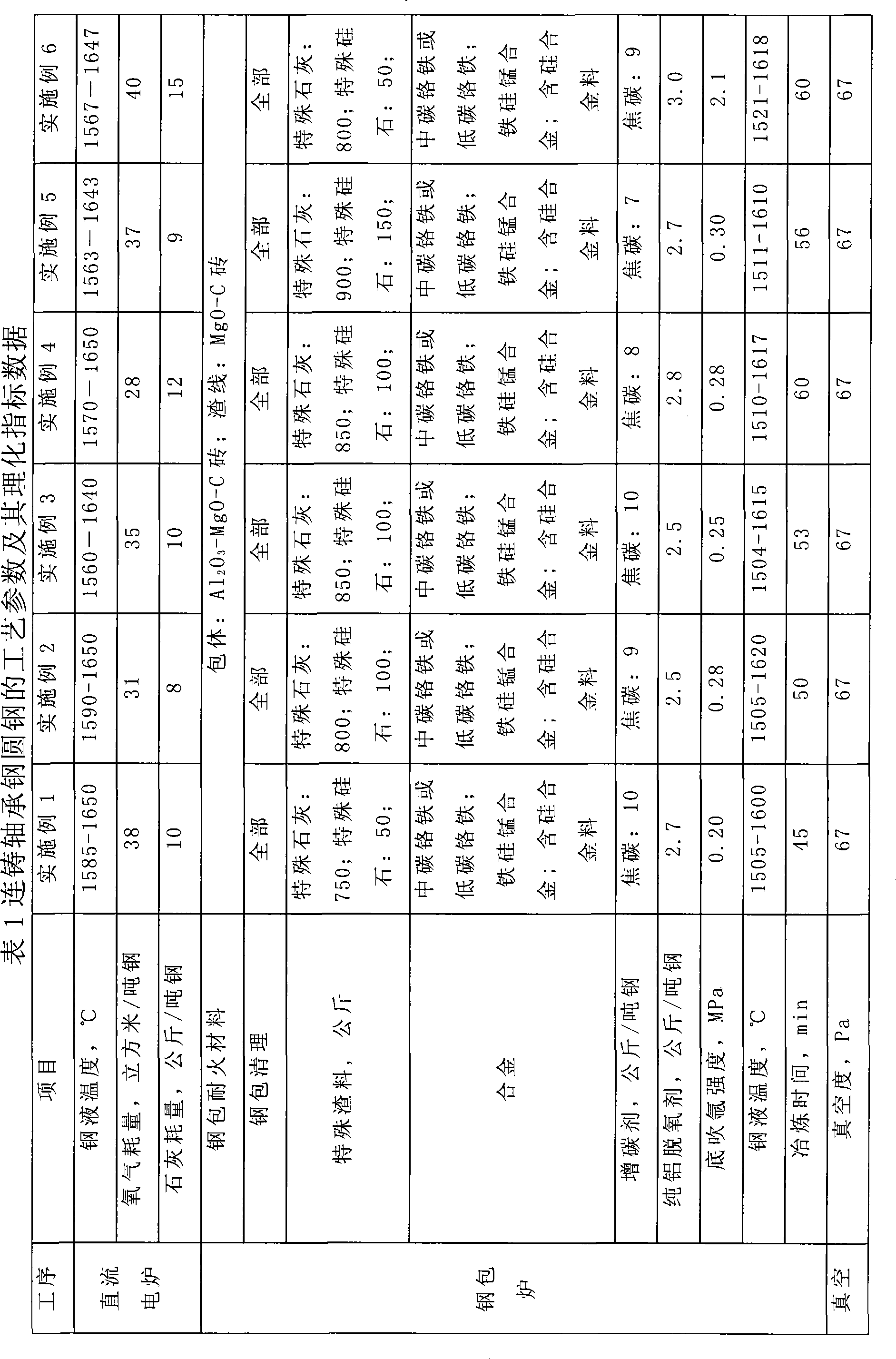

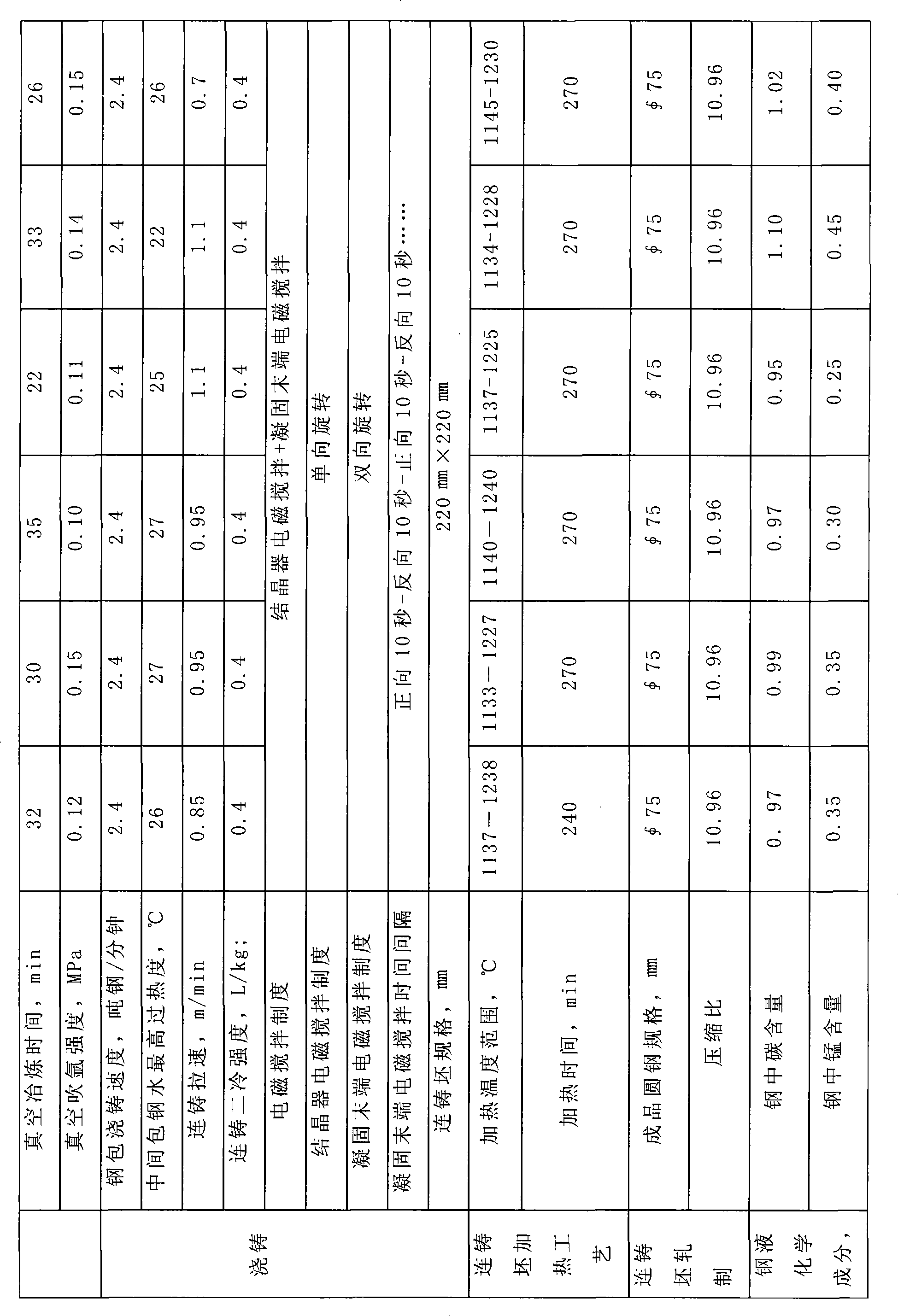

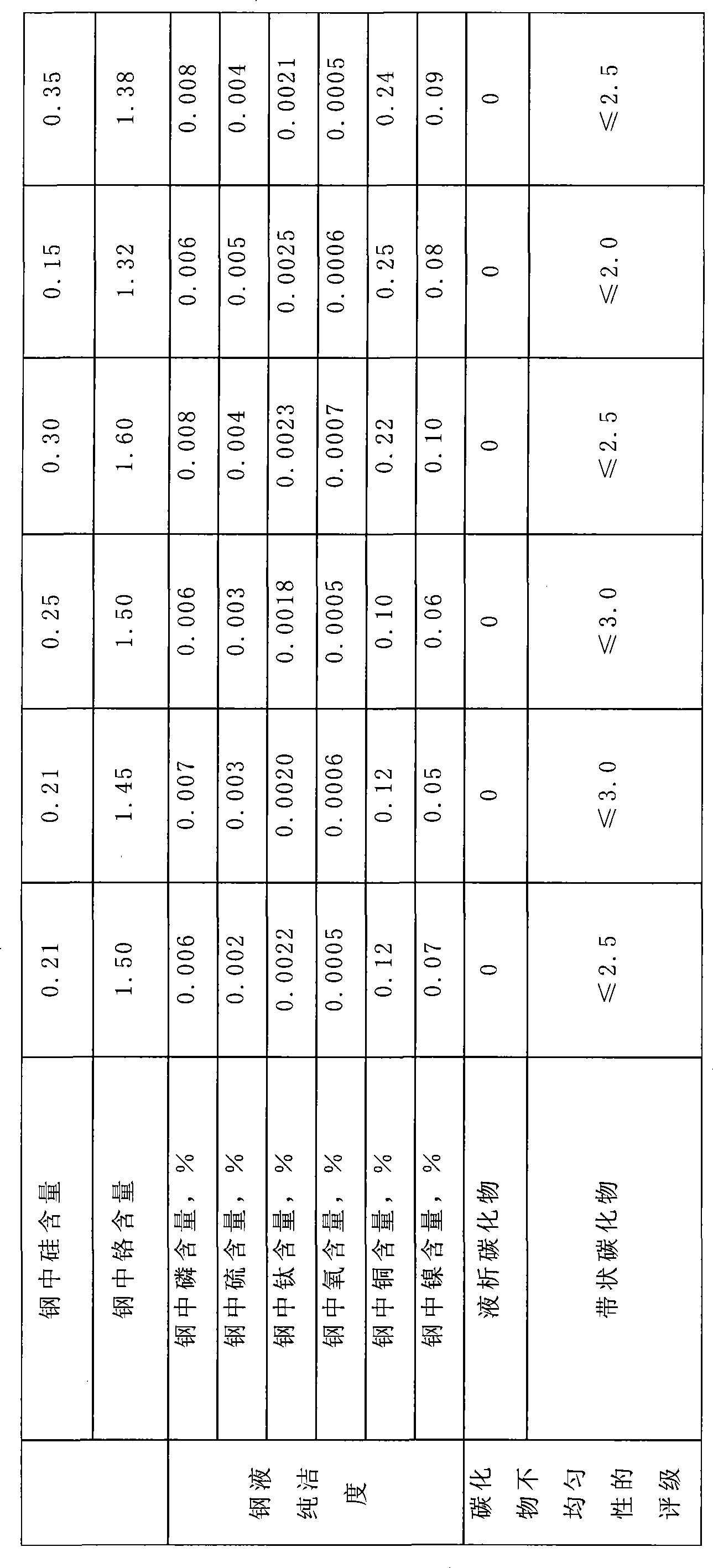

[0101] The present invention is further illustrated by the following examples.

[0102] Implement the present invention, produce 10 heats of steel (embodiment 1~10). Among them, the chemical composition of molten steel, the purity of molten steel, production process parameters, and physical and chemical performance indicators are shown in Tables 1-2.

[0103] The process flow is: molten steel refining→ladle pouring--tundish continuous casting bearing steel billet (220×220mm 2 )→Heating furnace to heat continuous casting bearing steel billets→Rolling mill to roll continuous casting bearing steel round bars with a specification of ∮65~75mm.

[0104] The first step is molten steel refining.

[0105] 1) In a direct-current electric furnace of more than 60 tons, low-phosphating and low-titanizing molten steel are carried out to reduce the residual phosphorus content and titanium content in the steel to less than 0.008% and less than 0.0005% respectively.

[0106] (1) In a DC ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com