Production method for preventing cracks on medium-carbon high manganese steel

A production method and technology of high manganese steel, applied in the field of iron and steel metallurgy, can solve problems such as surface defects of round steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

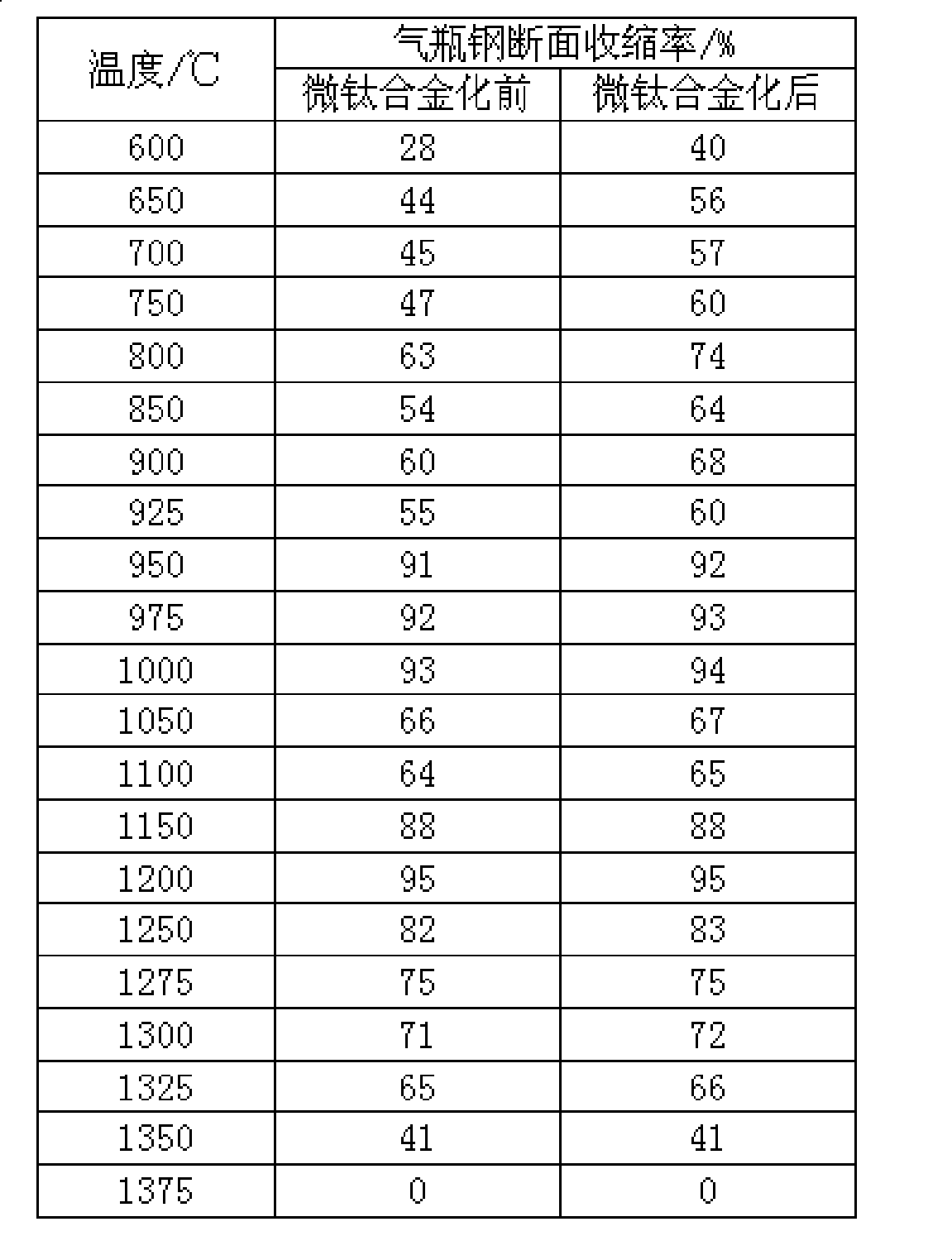

[0014] The preparation method of the medium carbon and high manganese steel billet used by the inventor in the past includes the following processes: converter smelting - LF+RH refining - billet continuous casting. Among them, micro-titanium alloying treatment is not performed, and in the original continuous casting process, the continuous casting pulling speed is 0.3-0.7 m / min, and the cooling strength is about 0.6-0.7 L / kg. The surface longitudinal crack defects are produced on the produced billet or the φ350mm round tube billet rolled from the billet, which is as high as 44% in severe cases. If the cooling intensity is 0.6-0.7L / kg, the surface temperature of the slab at the exit of the tension leveler in the second cooling zone is 750-800°C, the maximum recuperation rate of the slab surface is controlled within 120°C / m, and the maximum temperature drop rate Controlled within 87°C / m, due to the large surface recuperation rate and cooling rate of the billet, which has an adve...

Embodiment 1

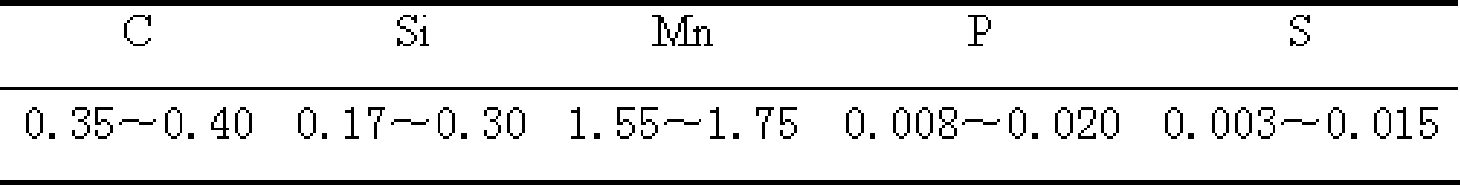

[0021] Example 1 Preparation of 37Mn high pressure gas cylinder steel

[0022] Process route: molten iron pretreatment—converter smelting—LF+RH vacuum treatment—360mm×450mm bloom continuous casting—rail beam rolling into φ350mm round billet.

[0023] The composition is accurately adjusted at the LF and RH refining stations. When the acid-soluble aluminum content in the steel is adjusted to 0.020% to 0.050% at the RH station, 0.8 to 1.0 kg of titanium-iron alloy is added per ton of steel (the Ti content in the alloy is about 40%), so that the [Ti] content in the steel is controlled to be 0.025% to 0.045%, the casting speed of the casting machine is 0.3 to 0.6 m / min, the cooling strength is 0.37 to 0.53 L / kg, and the second cooling zone of continuous casting is used. The surface temperature of the billet at the exit of the tension leveler is 850-890℃, the maximum recuperation rate of the billet surface is 30℃ / m, and the maximum temperature drop rate is 20℃ / m. After the casting ...

Embodiment 2

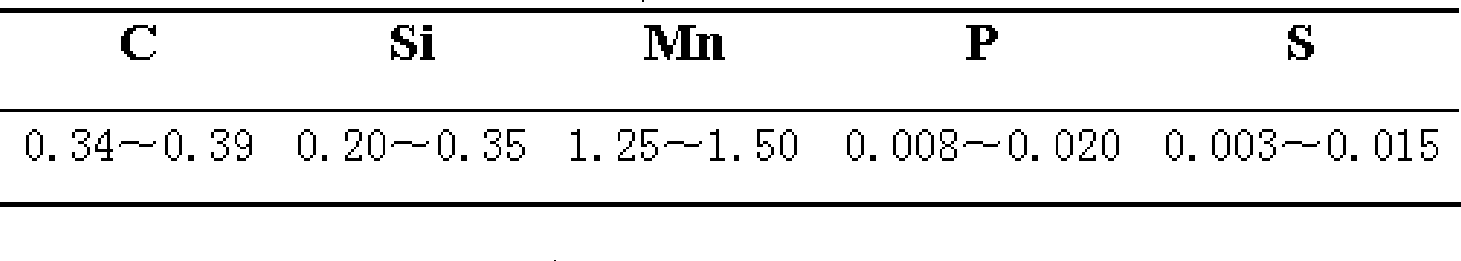

[0026] Example 2 Preparation of 37Mn5 steel for oil well pipe

[0027] Process route: molten iron pretreatment—converter smelting—LF+RH vacuum treatment—360mm×450mm bloom continuous casting—rail beam rolling into φ350mm round billet.

[0028] The composition is accurately adjusted at the LF and RH refining stations. When the acid-soluble aluminum content in the steel is adjusted to 0.015% to 0.045% at the RH station, 0.7 to 0.9 kg of titanium-iron alloy is added per ton of steel (the Ti content in the alloy is about 40%), the [Ti] content in the steel is controlled to be 0.020% to 0.040%, the casting speed of the casting machine during continuous casting production is 0.3 to 0.6m / min, the cooling strength is 0.37 to 0.53L / kg, and the second cooling zone of continuous casting is used. The surface temperature of the billet at the exit of the tension leveler is 850-890℃, the maximum recuperation rate of the billet surface is 30℃ / m, and the maximum temperature drop rate is 20℃ / m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com