Method for forming large-diameter stainless steel square tube

A forming method and stainless steel technology, applied in the field of stainless steel seamless steel pipe processing and manufacturing, can solve the problems of large loss of pipe head, rolling section deformation, instability, etc., and achieve high dimensional accuracy of the product, small degree of end surface instability, stable short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

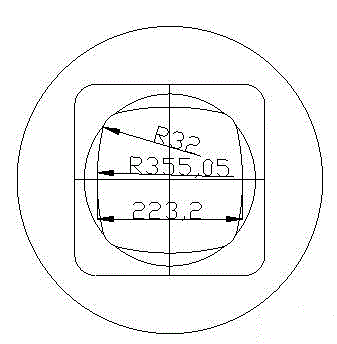

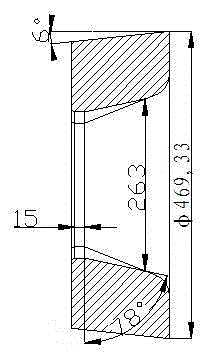

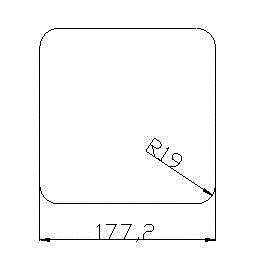

Image

Examples

Embodiment

[0044] (1) Cutting, that is, the raw material is a stainless steel circular steel pipe with an outer diameter of Φ255~Φ281mm and a wall thickness of 13.5±0.3mm.

[0045] ⑵, the first surface lubrication, that is, apply lubricant (calcium stearate + lime) on the outer surface of the steel pipe, and the lubricant must be applied evenly. Then, dry the lubricant on the surface of the steel pipe at a low temperature of less than 100°C.

[0046] (3) At one end of the steel pipe, use a grinding wheel cutting machine to cut 4 equal cuts in the axial direction to form 4 equal slices with a length of 150±10mm, and then hit the equal slices with a hammer to make the 4 equal slices All are close to the axis of the steel pipe, so that the distance between the two opposite equal slices is less than 200mm;

[0047] ⑷. Weld the drawing head on one of the equal slices. The diameter of the drawing head is 150mm-180mm.

[0048] ⑸. The steel pipe welded with the drawing head is drawn through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com