Black ferric arsenate crystal and synthesis method thereof

A synthesis method, a technology of iron arsenate, applied in the fields of iron compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of unclear microstructure, and achieve the effect of good application potential of arsenic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

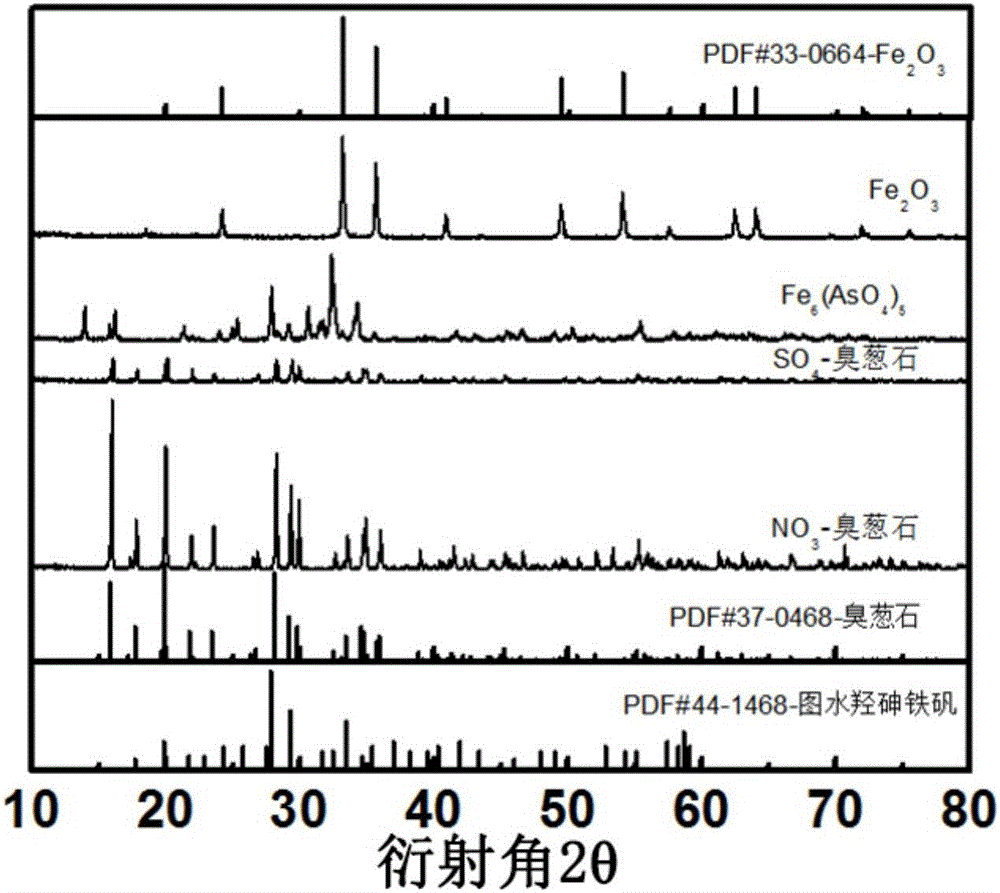

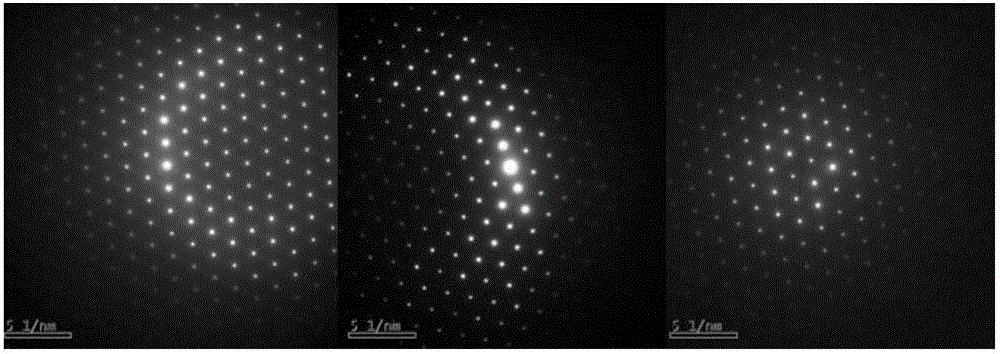

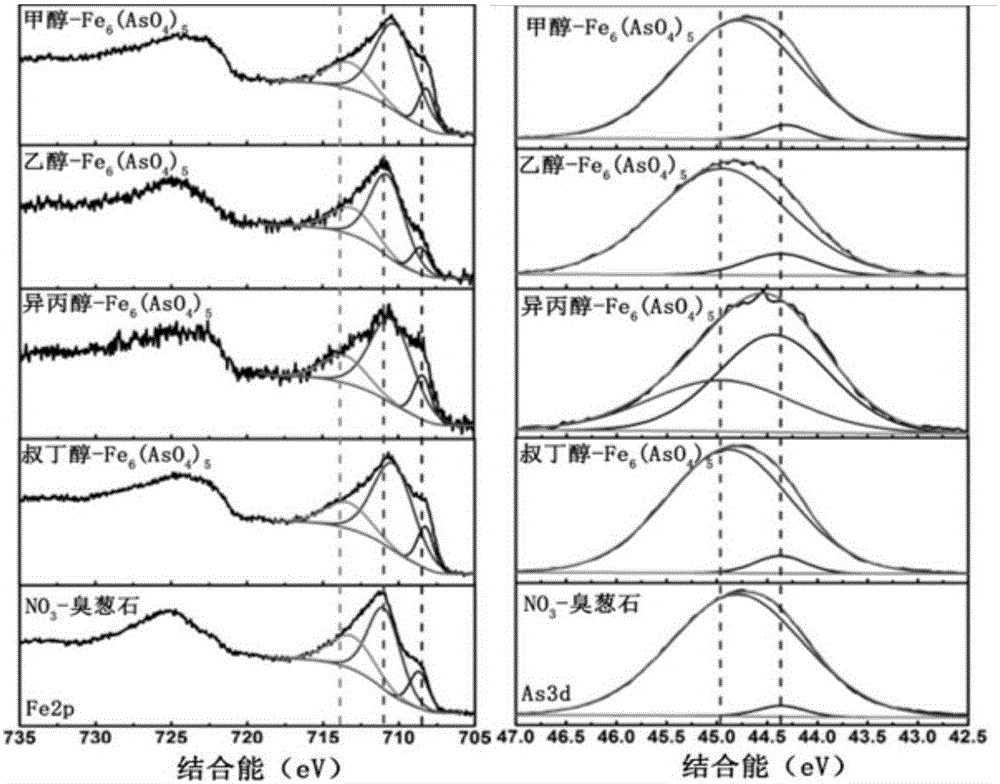

Embodiment 1

[0036] Sodium arsenate and ferric nitrate are used as As(V) source and Fe(III) source respectively to configure scorodite synthesis solution, the molar ratio of As(V) / Fe(III) in the solution is 1.5, and the concentration of arsenic is 0.21mol / L, nitric acid concentration is 2.6mol / L. The solution was directly reacted at 200°C for 8 hours to form blue-green scorodite ( figure 1 NO in 3 - scorodite and Figure 6 a), so the solution is called scorodite synthesis solution (synthesis solution). Mix isopropyl alcohol and scorodite synthetic solution in proportion, control the alcohol volume in the mixed solution to be 50%, the mol ratio of Fe / As is 1.5, the As concentration is 0.10mol / L, and the nitric acid concentration is 1.3mol / L, and then Put it into a stainless steel reaction kettle with a filling degree greater than 50%, and obtain a black solid after reacting at 200° C. for 8 hours. A black powder can be obtained after the solid is subjected to centrifugation, repeated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com