Technology for efficiently and selectively separating zinc in zinc sulfide concentrate

A zinc sulfide concentrate and selective technology, which is applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the problems of increased purification process, large consumption, increased production cost, etc., and achieve simplified process and equipment, Effects of resource saving and process strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

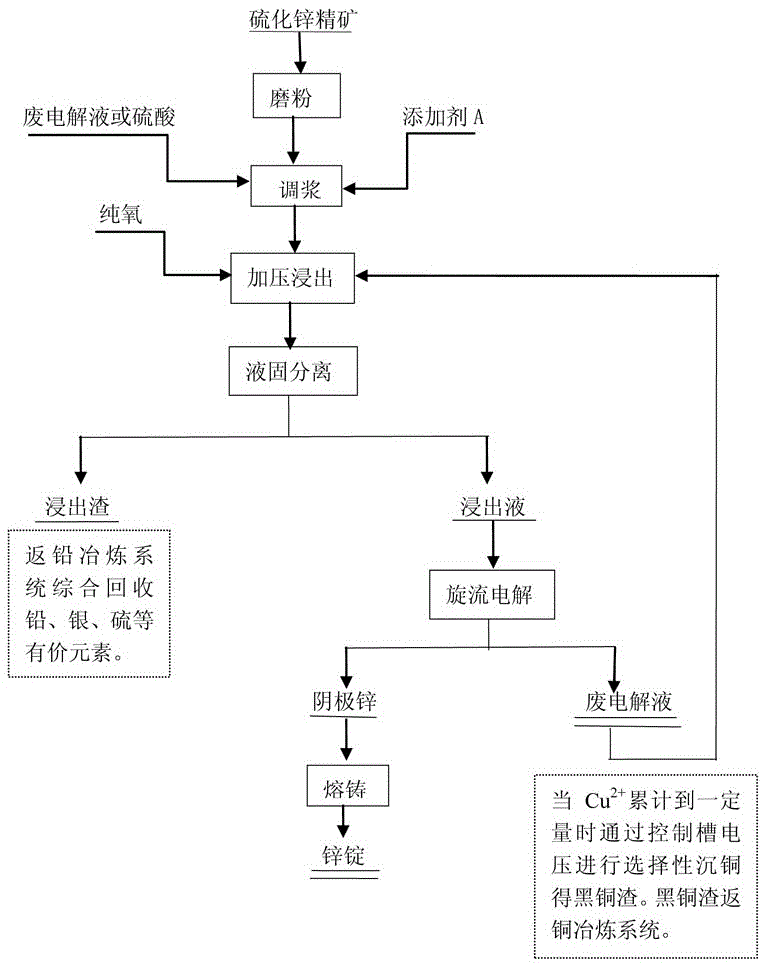

Method used

Image

Examples

Embodiment 1

[0038] Wet grind 500g of zinc sulfide concentrate (Zn16.58%; As0.13%; S31.68%; Pb3.85%; Ag26g / t; Fe12.37%) until the particle size is less than 200 mesh, and then mix it with dilute sulfuric acid , and then poured into the autoclave. During the leaching process, pure oxygen is continuously fed and the technical conditions are controlled: the concentration of sulfuric acid is 160g / L, the liquid-solid ratio is 5:1, the temperature is 140°C, the adjustment and maintenance pressure is 1.2MPa, and the stirring speed is 600r / min. , The reaction time is 2 hours. After the oxidation leaching is completed, the ore slurry is discharged out of the autoclave for liquid-solid separation. Zn is represented by Zn 2+ After entering the leaching solution, the zinc leaching rate is as high as 98.73% through laboratory analysis, and the leaching slag tempering method lead smelting system recovers Ag, Pb, S and other valuable elements. The zinc-containing leaching solution is directly subjected t...

Embodiment 2

[0040]Wet grind 500g of zinc sulfide concentrate (Zn51.58%; As0.15%; S28.73%; Pb5.07%; Ag37g / t; Fe15.11%) until the particle size is less than 200 mesh, and then mix it with dilute sulfuric acid , and then poured into the autoclave. During the leaching process, pure oxygen is continuously fed and the technical conditions are controlled: the concentration of sulfuric acid is 160g / L, the liquid-solid ratio is 6:1, the temperature is 150°C, the adjustment and maintenance pressure is 1.4MPa, and the stirring speed is 600r / min. , The reaction time is 2.5h. After the oxidation leaching is completed, the ore slurry is discharged out of the autoclave for liquid-solid separation. Zn is represented by Zn 2+ After entering the leaching solution, the zinc leaching rate is as high as 99.08% through laboratory analysis, and the leaching slag tempering method lead smelting system recovers Ag, Pb, S and other valuable elements. The zinc-containing leaching solution is directly subjected to sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com