Method for treating arsenic pollution of copper smelt industry

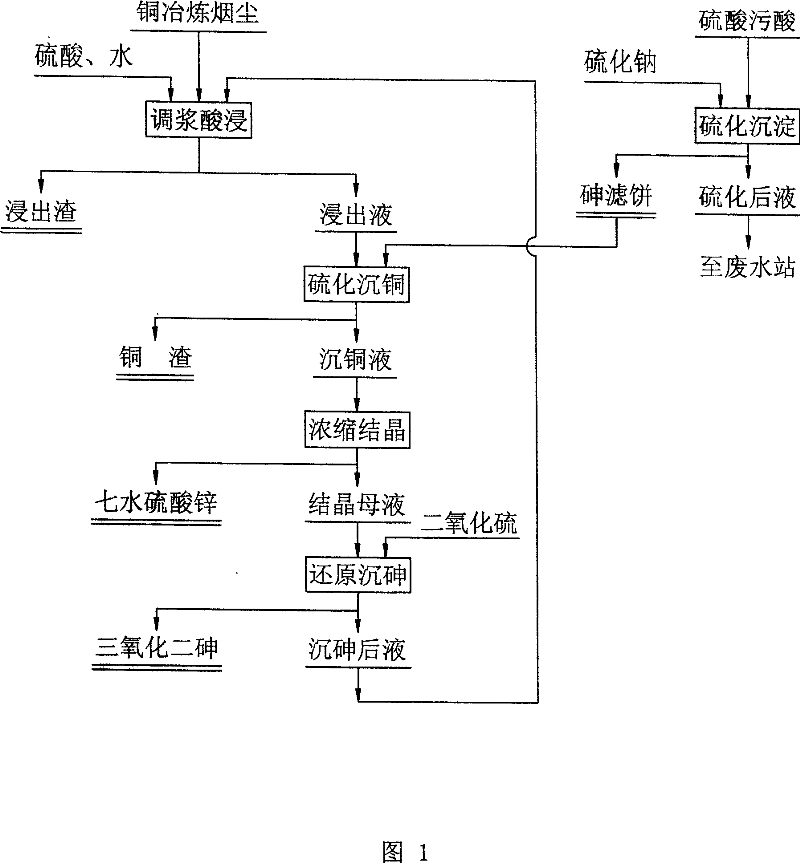

A technology for copper smelting and arsenic pollution, which is applied in the field of arsenic pollution control in copper smelting industry, can solve the problems of high disposal cost, arsenic filter cake outlet, potential environmental threat, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] The main components of a copper smelting dust are (%): Cu 4, As 8, Zn 10, Cd 2, Pb 25, Bi 2; the main components of polluted acid arsenic filter cake are (%): Cu 1.7, As 26, S 18.

[0014] The implementation process is as follows:

[0015] 1) Sulfuric acid leaching: the above-mentioned copper smelting dust is leached with sulfuric acid solution, the liquid-solid ratio is 4:1, the temperature is controlled at 50-80°C, the final acid is 5g / L, the leaching time is 2h, and the leaching residue and leaching solution are obtained by filtration.

[0016] 2) Copper sulfide precipitation: add the above-mentioned polluted acid arsenic filter cake under stirring state of the leaching solution, control the temperature at 50-80°C, carry out the copper precipitation reaction, stop adding polluted acid arsenic filter cake when the reaction reaches the end, and filter to obtain copper slag and copper precipitation solution . Judgment method for the reaction end point: take a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com