Treatment technology for high-arsenic acid industrial wastewater

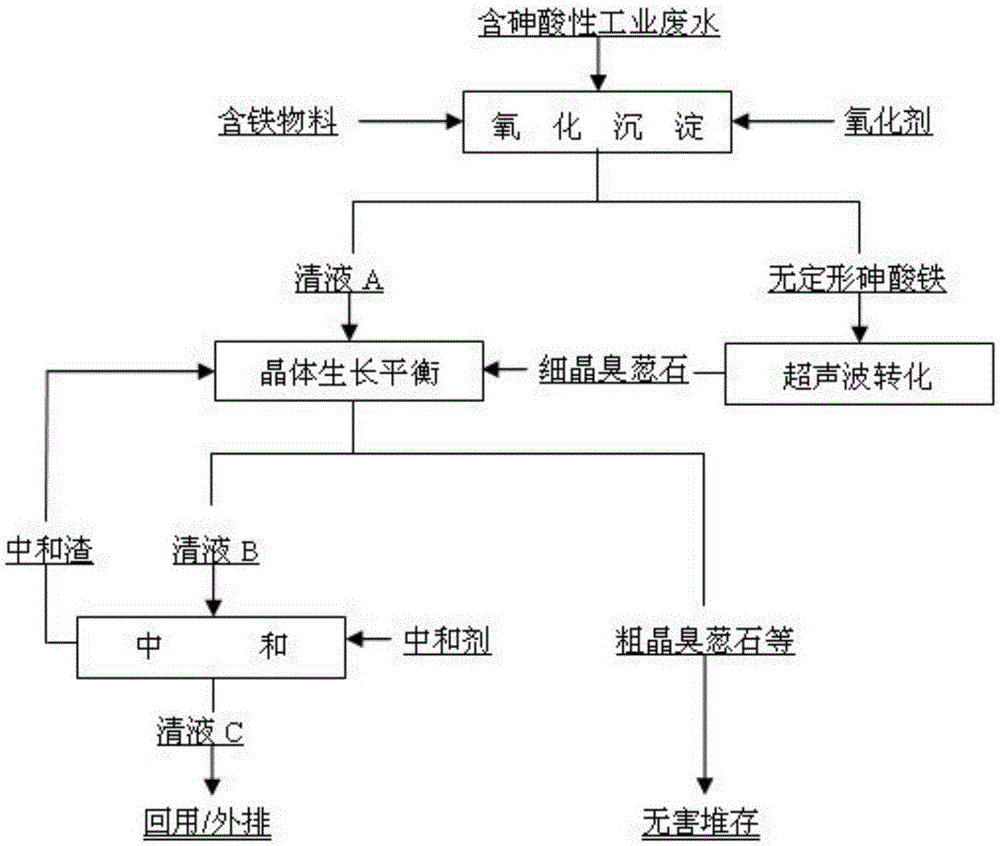

A technology for industrial wastewater and treatment process, applied in the field of metallurgical environmental protection, can solve the problems of poor stability of arsenic precipitates, high energy consumption for crystal transformation, and increased energy consumption, and achieves the effects of good crystallization, reduced energy consumption, and reduced treatment volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A kind of industrial polluted acid, containing 3-8% of sulfuric acid, containing 20g / L of arsenic, the quantity to be treated is 360m 3 / d. First, mix the ferrous sulfate solution into the dirty acid and send it to the electrolytic cell for electro-oxidation in the cell, Fe(II) becomes Fe(III), As(III) becomes As(V), and amorphous iron arsenate precipitates in the liquid Produced, the rough separation of solid and liquid is carried out outside the tank. Place the precipitate at a frequency of 15-500kHz and an intensity of 0.3-500W / cm 2 The ultrasonic wave is irradiated at room temperature for 10-120 minutes, and the precipitation is transformed into fine crystal scorodite. Then remix the fine-crystalline scorodite and liquid phase A, add calcium sulfate slag and stir in the reaction tank, equilibrate for 0.5-8 hours, the fine crystals grow into coarse crystals, and then carry out solid-liquid separation. The co-precipitate of coarse crystalline scorodite...

Embodiment 2

[0035] A kind of industrial sewage acid, containing 80-150g / L sulfuric acid and 8g / L arsenic, the quantity to be treated is 800m 3 / d. Two systems were used, each handling 50% of the total. First, add ferric sulfate solution and hydrogen peroxide into the reaction tank A to form amorphous ferric arsenate precipitate in the dirty acid, and carry out coarse solid-liquid separation. Fully mix the precipitate with a small amount of co-precipitation of coarse crystalline scorodite and calcium sulfate (as a seed crystal), and then place it at a frequency of 15-500kHz and an intensity of 0.3-500W / cm 2 The ultrasonic wave is irradiated at 20-95°C for 10-60 minutes, and the precipitation is transformed into fine-crystalline scorodite (co-precipitate containing a small amount of coarse-crystalline scorodite and calcium sulfate). Then re-mix it with liquid phase A and add calcium sulfate slag to stir in the reaction tank, equilibrate for 0.5-8 hours, fine crystals grow into coarse cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com