Method for preparing quaternary ammonium salt cationic absorbing agent by using manioc straw/ manioc waste and application

A cationic type, cassava residue technology, applied in the field of environment and chemistry, to achieve the effect of less secondary pollution, good treatment effect, and convenient regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

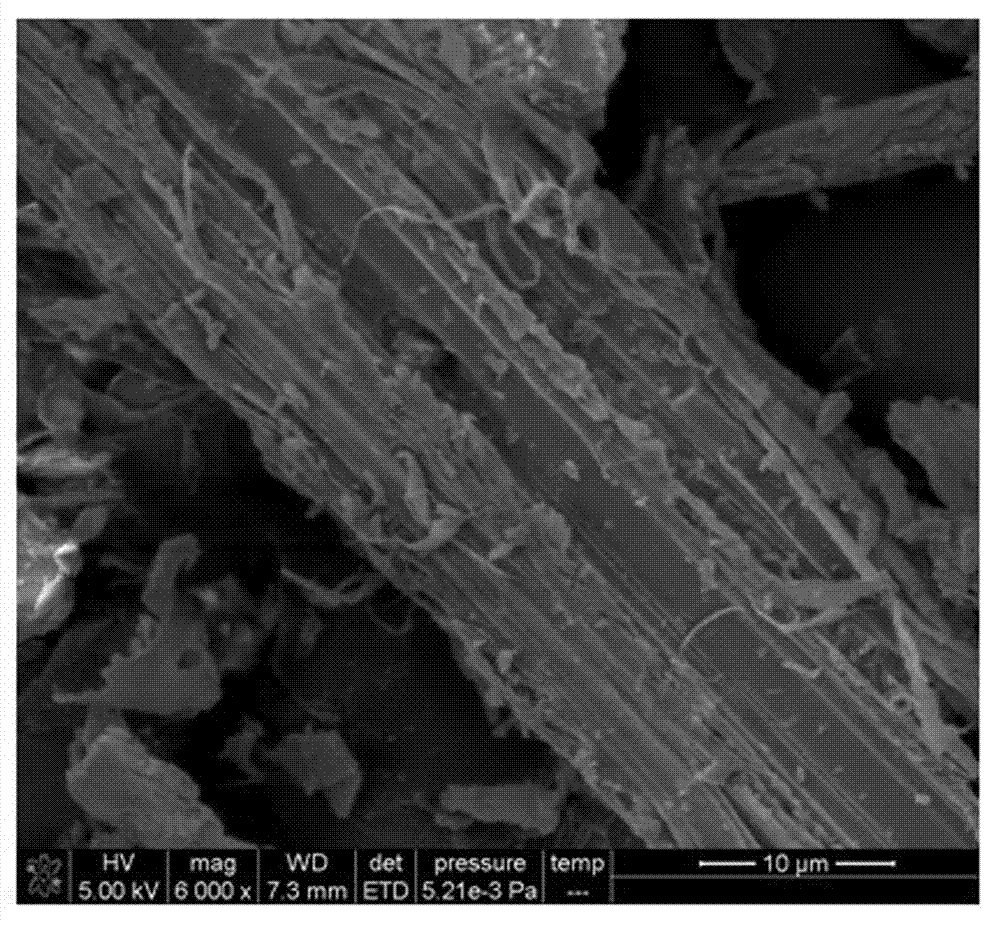

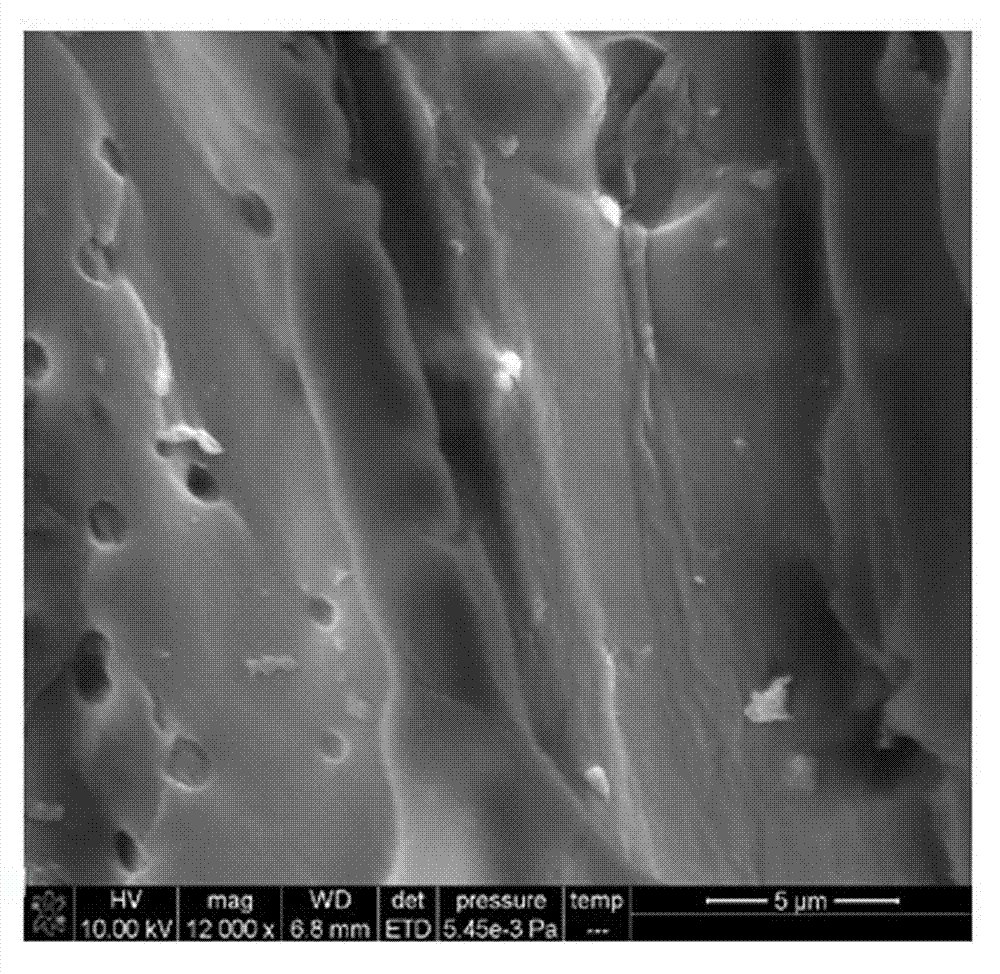

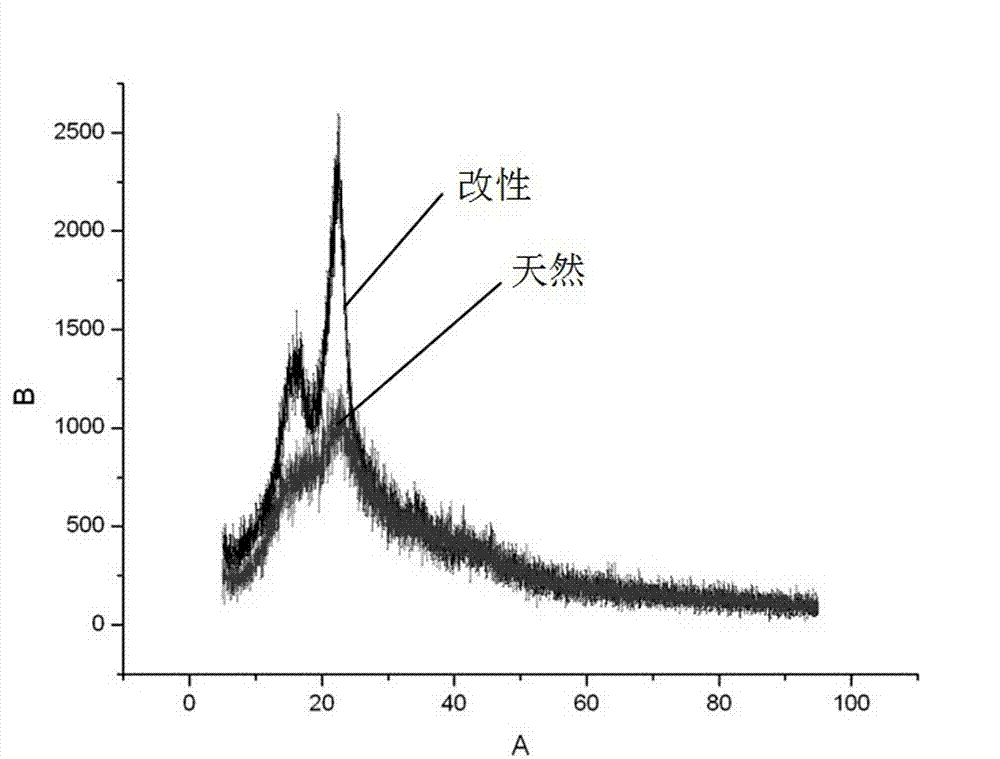

[0027] Embodiment 1: the preparation of quaternary ammonium salt cationic adsorbent

[0028] Wash cassava stalks, dry, crush, take 10g of powder with a particle size of 80 mesh, soak and stir in 2mol / L NaOH 200ml for 10h, filter, wash until neutral, and dry; weigh 2g of the dried product and put it into 50ml of epoxy chlorine Propane and 50ml N,N-dimethylformamide, stirred at 100°C for 1h; then added 3ml of ethylenediamine, stirred at 100°C for 0.5h; added 5ml of triethylamine, stirred at 100°C for 4h; NaOH, HCl, 50% ethanol, and distilled water were washed until neutral, and dried to obtain 1.8 g of quaternary ammonium salt cationic adsorbent. The appearance is yellow powder, the Zeta potential is 42, and the pH value of the aqueous solution is 5.8.

Embodiment 2

[0029] Embodiment 2: Preparation of quaternary ammonium salt cationic adsorbent

[0030]Wash cassava stalks, dry them, crush them, take 15g of powder with a particle size of 80 mesh, soak and stir in 200ml of 3mol / L NaOH for 8h, filter, wash until neutral, and dry; weigh 2g of the dried product and put it into 50ml of epoxy chlorine Propane and 50ml N,N-dimethylformamide, stirred at 100°C for 1h; then added 4ml of ethylenediamine, stirred at 100°C for 0.5h; added 10ml of triethylamine, stirred at 100°C for 4h; NaOH, HCl, 50% ethanol, and distilled water were washed to neutrality, and dried to obtain 1.9 g of cationic adsorbent. The appearance is yellow powder, the Zeta potential is 35, and the pH value of the aqueous solution is 4.9.

Embodiment 3

[0031] Embodiment 3: Preparation of quaternary ammonium salt cationic adsorbent

[0032] Wash cassava stalks, dry them, crush them, take 12g of powder with a particle size of 80 mesh, soak and stir in 200ml of 2mol / L NaOH for 8h, filter, wash until neutral, and dry; weigh 2g of the dried product and put it into 40ml of epoxy chlorine Propane and 40ml N,N-dimethylformamide, stirred at 50°C for 1.5h; then added 5ml of ethylenediamine, stirred at 50°C for 1.5h; added 5ml of triethylamine, stirred at 50°C for 3h; at room temperature, respectively Wash with NaOH, HCl, 50% ethanol, and distilled water until neutral, and dry to obtain 1.8 g of cationic adsorbent. The appearance is yellow-brown powder, the Zeta potential is 33, and the pH value of the aqueous solution is 5.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com