Method for removing arsenic from electronic grade phosphoric acid generated by wet-process phosphoric acid

A technology of electronic grade phosphoric acid and wet phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

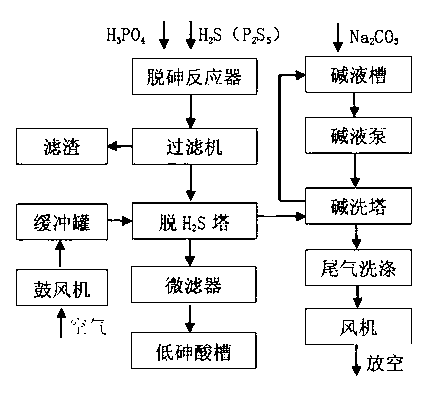

Image

Examples

Embodiment

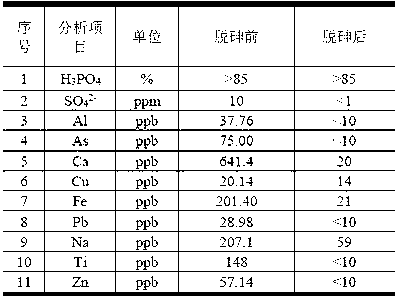

[0023] A factory adopts the technology of the present invention to remove arsenic in the production process of electronic grade phosphoric acid, and the specific scheme is as follows:

[0024] ① Add H to the arsenic removal reactor 2 S and phosphoric acid, and keep the reaction temperature at 80°C, and stir;

[0025] ② Filter the concentrated liquid from the arsenic removal reactor through a filter to separate the arsenic residue from the clear liquid;

[0026] ③ After the clear liquid is heated to a certain temperature, use a pump to inject H to remove 2 The S tower uses air bubbling and negative pressure suction to blow off the residual hydrogen sulfide gas in the acid; 2 The acid flow rate of the S tower is stable, the temperature of the preheating acid entering the tower is stable, and the amount of stripping air is stable;

[0027] ④ take off H 2 S acid enters the storage tank through a microfilter for standby, ensuring that the arsenic content of low arsenic acid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com