A processing method for improving the yield and quality of resistant dextrin

A technology of resistant dextrin and a processing method, which is applied in the field of starch deep processing, can solve the problems of reducing product yield, production efficiency, waste of glucose syrup, etc., and achieves improving product yield and product quality, and improving content and product yield. , the effect of improving the effect and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

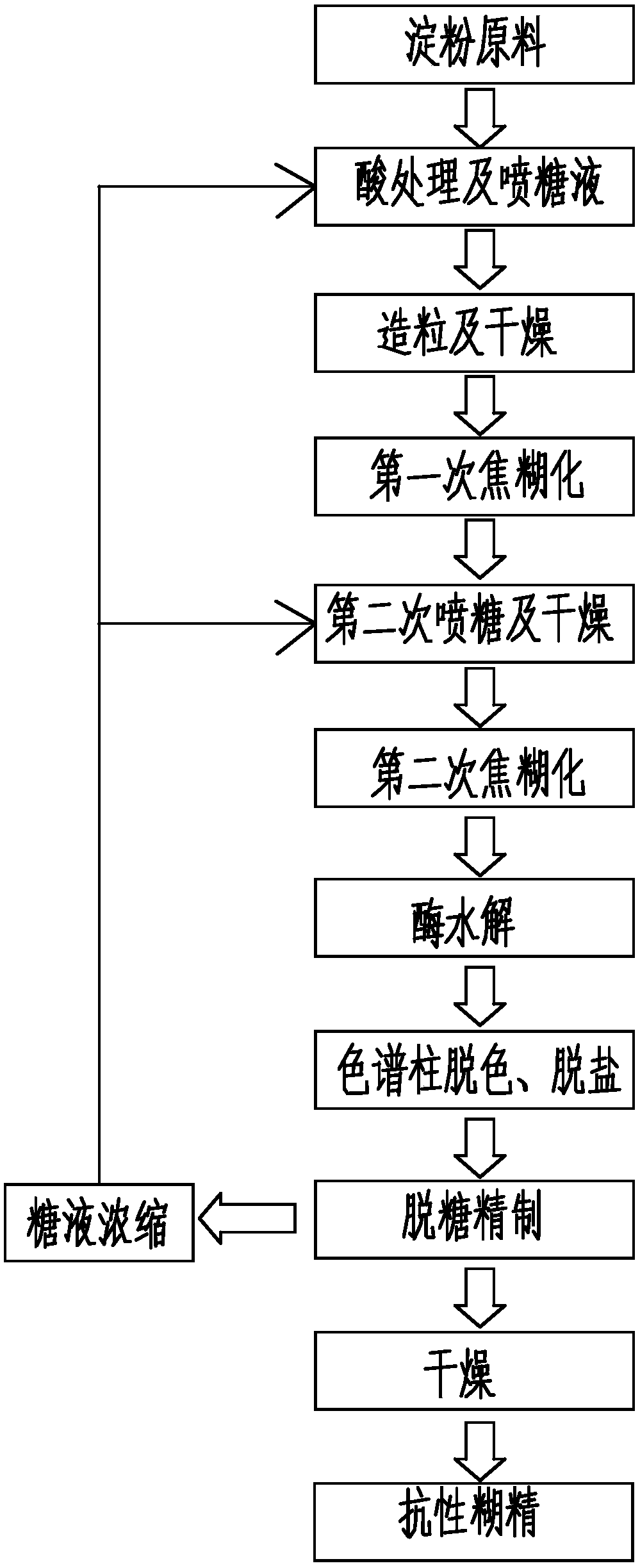

Image

Examples

Embodiment 1

[0035] A processing method for improving the yield and quality of resistant dextrin, using cornstarch as a raw material, is characterized in that the specific steps are as follows:

[0036] (1) Sugar spraying treatment: Spray the hydrochloric acid solution of concentration 1.2% after the cornstarch raw material is pre-dried to the water content of 4%. The spraying amount of liquid is 30% of starch raw material weight after drying;

[0037] (2) Granulation treatment: pre-dry the cornstarch raw material after the sugar spraying treatment in step (1) to a water content of 15% at 80°C, and then granulate it into corn with a particle size of 100 mesh by a dry granulator starch granules, and dry them to a moisture content of 3%;

[0038] (3) The first scorched gelatinization: the dried cornstarch granules in step (2) are heated outside the container by dry heat steam to a high temperature of 120°C, and treated at this temperature for 300 minutes to make the cornstarch and The suga...

Embodiment 2

[0046] A processing method for improving the output rate and quality of resistant dextrin, using wheat starch as a raw material, is characterized in that the specific steps are as follows:

[0047] (1) Sugar spraying treatment: soaking the wheat starch raw material with a concentration of 0.05% in a compound acid solution for 30min, the compound acid solution is compounded by hydrochloric acid and citric acid according to the ratio of 5:1 by weight, the compound acid solution The weight ratio to the starch raw material is 3:1; then the wet starch raw material is separated by centrifugation, and the wet starch raw material is dried at 90°C to a water content of 8%, and then sprayed with a concentration of 50% Sugar solution, the spraying amount of the sugar solution is 20% of the starch raw material weight after drying;

[0048] (2) Granulation treatment: Pre-dry the wheat starch raw material after the sugar spraying treatment in step (1) to a water content of 10% at 60°C, and ...

Embodiment 3

[0058] A processing method for improving the output rate and quality of resistant dextrin, using rice starch as a raw material, is characterized in that the specific steps are as follows:

[0059] (1) Sugar spraying treatment: Soak the rice starch raw material with a sulfuric acid solution with a concentration of 0.05% for 10-90min. The weight ratio of the sulfuric acid solution to the rice starch raw material is 2:1, and then filter the separated wet starch raw material. Dried to a water content of 6%, and then sprayed with a concentration of 60% sugar solution, the spray amount of the sugar solution was 30% of the weight of the dried rice starch raw material;

[0060] (2) Granulation treatment: pre-dry the rice starch raw material after the sugar spraying treatment in step (1) to a water content of 16% under the condition of 90°C, and then granulate it into starch granules with a particle size of 20 meshes by a granulator, and dry it to a moisture content of 5%;

[0061] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com