Advanced treatment method for arsenic-containing wastewater

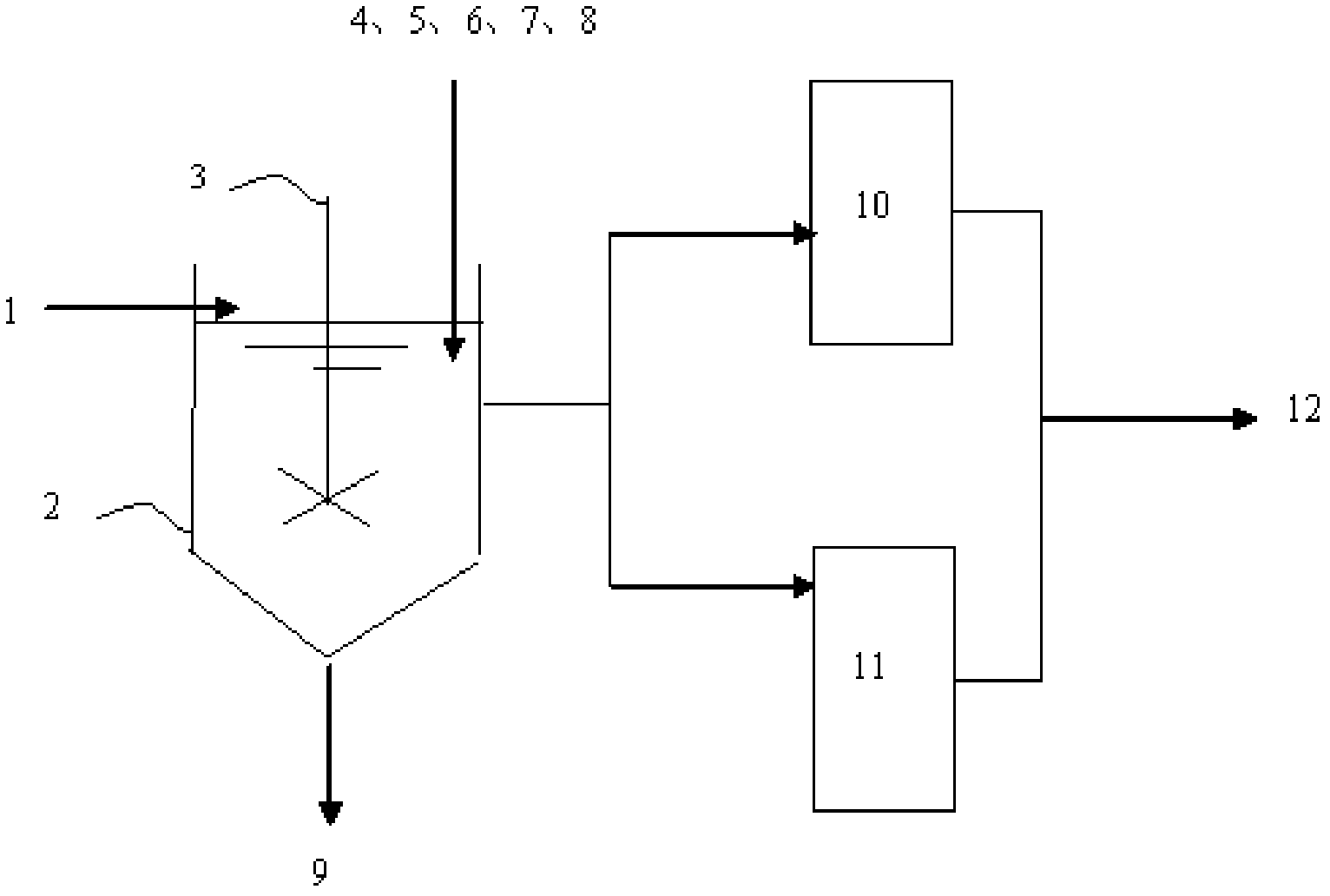

A waste water and concentration technology, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve complex regeneration and desorption process, secondary pollution of extractant, generated sewage Large amount of mud and other problems, to achieve the effect of increasing arsenic removal efficiency, shortening settling time, and high arsenic removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The method of the invention treats 1L of prepared wastewater containing 1mg / L of trivalent arsenic.

[0015] Introduce 5mg / L ozone into the reaction tank, stir for 5min, then add 150mg / L 10% ferric chloride solution, and add sodium hydroxide to adjust pH=8, stir rapidly for 0.1min, then add 0.1mg / L 0.1 % polyacrylamide solution, stirred rapidly for 0.1min, stirred slowly for 5min, and settled for 10min. After the sludge was separated, the supernatant was filtered in a sand filter. The As content of the treated wastewater was 0.008 mg / L, the Fe content was 0.02 mg / L, and the pH was 7.5.

Embodiment 2

[0017] The method of the invention treats 10L of prepared wastewater containing 10mg / L of trivalent arsenic.

[0018] Introduce 100ml / min air into the reaction tank, stir and react for 60min, then add 500mg / L 1% polyferric sulfate solution, and add calcium oxide to adjust pH=6, stir rapidly for 1min, then add 1mg / L 0.1% polyferric sulfate solution For acrylamide solution, stir rapidly for 1 minute, stir slowly for 10 minutes, settle for 30 minutes, and after the sludge is separated, filter the supernatant through a membrane filter. The As content of the treated wastewater was 0.009 mg / L, the Fe content was 0.01 mg / L, and the pH was 6.8.

Embodiment 3

[0020] The method of the invention treats 100L of prepared wastewater containing 100mg / L of trivalent arsenic.

[0021] Add 100mg / L hydrogen peroxide into the reaction tank, stir for 10min, then add 1000mg / L10% polyferric sulfate solution, add sodium carbonate to adjust pH=7, stir rapidly for 1min, then add 10mg / L 0.1% polyferric sulfate solution For the acrylamide solution, stir rapidly for 1 minute, stir slowly for 10 minutes, and settle for 30 minutes. After the sludge is separated, the supernatant enters the filter bag for filtration. The As content of the treated wastewater was 0.005 mg / L, the Fe content was 0.01 mg / L, and the pH was 6.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com