Method for recycling rhenium, arsenic and copper from sulfuric acid wastewater of copper smelting flue gas purification system

A flue gas purification system and copper smelting technology, which is applied in the fields of copper, rhenium and arsenic recovery, can solve the problems of waste of high value-added metals, poor technical and economic efficiency, waste of resources, etc., and achieve comprehensive utilization of energy consumption and all resources, simple equipment, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

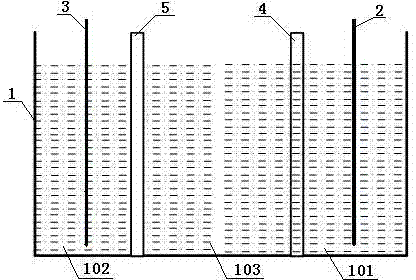

[0019] refer to figure 1 : The method for reclaiming rhenium, arsenic and copper from sulfuric acid wastewater of copper smelting flue gas purification system, the steps are as follows: a. the highly acidic sulfuric acid wastewater obtained by flue gas purification is placed in electrolytic cell 1, and electrolytic cell 1 is equipped with cathode 2 and anode 3. The sulfonic acid-based anion-selective membrane 5 is placed in the anode area, and the polysulfone-based cation-selective mold is placed in the cathode area; the sulfonic acid-based anion-selective membrane and the polysulfone-based cation-selective mode separate the electrolytic cell into an anode area 102 and an intermediate area 103 and cathode area 101; the main component concentration of highly acidic sulfuric acid wastewater is: sulfuric acid 90g / L, copper 1.0g / L, rhenium 60mg / L, arsenic 7g / L;

[0020] B. prepare peroxymonosulfuric acid in anode area 102 as strong oxidizing agent: the anode area 102 is used as a...

Embodiment 2

[0024] The method for recovering rhenium, arsenic, and copper from the sulfuric acid wastewater of the copper smelting flue gas purification system provided in this embodiment, the specific steps are:

[0025] A. the concentration of main components of highly acidic sulfuric acid wastewater is: sulfuric acid 120g / L, copper 0.6g / L, rhenium 20mg / L, arsenic 3g / L; all the other are the same as embodiment 1;

[0026] B. prepare peroxymonosulfuric acid in anode area 102 as strong oxidizing agent: the anode area 102 is used as an electrolysis device, the anode is a pure platinum plate, and the cathode is a lead plate, and the anode chamber is isolated from the cathode chamber with a sulfonic acid-based anion membrane material; According to the capacity of highly acidic sulfuric acid wastewater in the anode area 102, add 0.5g / L ammonium thiocyanate additive; control the electrolysis voltage to 5.5V, and the current density to 2500A / m 2 , the reaction temperature is 20°C, the electroly...

Embodiment 3

[0029] The method for recovering rhenium, arsenic, and copper from the sulfuric acid wastewater of the copper smelting flue gas purification system provided in this embodiment, the specific steps are:

[0030] A. the concentration of main components of highly acidic sulfuric acid wastewater is: sulfuric acid 70g / L, copper 0.3g / L, rhenium 10mg / L, arsenic 5g / L; all the other are the same as embodiment 1;

[0031] b. prepare peroxymonosulfuric acid in the anode area 102 as a strong oxidant: the anode area 102 is used as an electrolytic device, the anode is titanium-plated platinum, the cathode is thermal shock graphite, and the anode chamber is isolated from the cathode chamber with a sulfonic acid-based anion membrane material ; According to the capacity of highly acidic sulfuric acid wastewater in the anode area 102, add 0.7g / L of ethylenediamine additive; control the electrolysis voltage to 6V, and the current density to 4000A / m 2 , the reaction temperature is 30°C, the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com