Method for recovering arsenic from scrap material containing arsenic and copper produced in process of copper smelting

A technology for recovering arsenic from copper waste, applied in the field of arsenic recovery, which can solve the problems of large equipment footprint, high production cost, and long process, and achieve the effects of small equipment footprint, improved operating efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Mix and stir the final reduction solution and the arsenic sulfide filter cake at a liquid-to-solid ratio of 7:1.

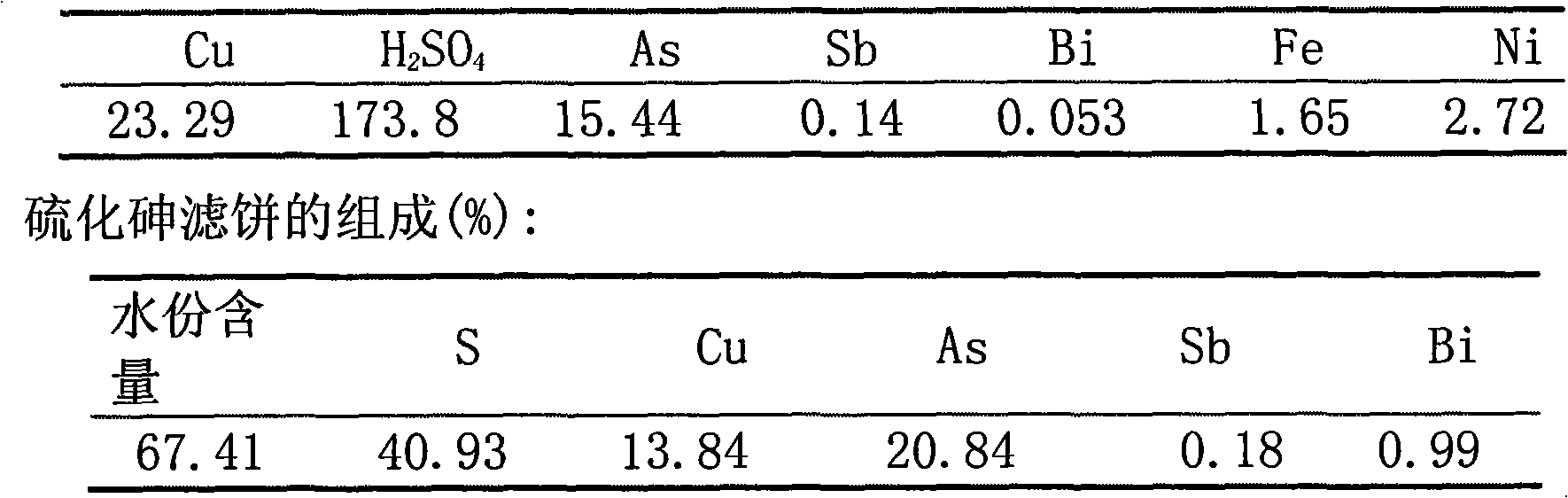

[0015] The composition of the final reduction solution (g / L):

[0016]

[0017] The mixed slurry is pre-heated to about 50°C and pumped into the reaction kettle. The pressure of the reactor is kept at 10~12kg / cm 2 , the temperature of the reaction kettle was kept at 117-119°C, the rotation speed of the mixer was 100rpm, and the compressed air volume was 600N / hr. After five hours, after the slurry in the reactor is extracted out and cooled, the leaching solution obtained by filtering is formed (gram / liter):

[0018]

[0019] The leaching rate of As reaches 96.47%.

[0020] The slag composition (%) obtained by washing the leached slag with water:

[0021]

[0022] The slag rate of the leaching residue is 33.83%.

[0023] After fine filtration, the leachate is passed through SO 2 Gas reduction crystallization, air volume maintained at 300m 3 Af...

Embodiment 2

[0025] Mix and stir the final reduction solution and the arsenic sulfide filter cake at a liquid-to-solid ratio of 8:1.

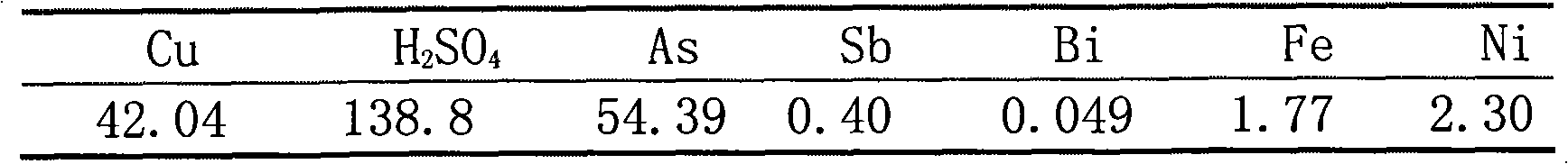

[0026] The composition of the final reduction solution (g / L):

[0027]

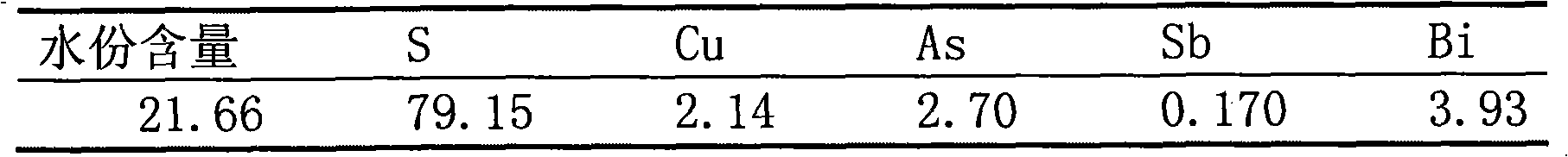

[0028] Composition (%) of arsenic sulfide filter cake:

[0029]

[0030] The mixed slurry is pre-heated to about 50°C and pumped into the reaction kettle. Reactor pressure maintained at 10.5kg / cm 2 , The temperature of the reaction kettle is kept at 90-115°C, the rotation speed of the mixer is 80rpm, and the compressed air volume is 600N / hr. After four hours, after the slurry in the reactor was extracted and cooled, the leaching solution obtained by filtering was composed (gram / liter):

[0031]

[0032] The leaching rate of As reaches 95.74%.

[0033] The composition of the slag obtained by washing the leached slag with water (g / L):

[0034]

[0035] The slag rate of the leaching slag is 37.21%.

[0036] After fine filtration, the leachate is passed through SO 2 Gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com