Construction regenerated binding material prepared from construction garbage and preparation method thereof

A technology for recycling cementitious materials and construction waste, applied in cement production, etc., can solve problems such as environmental pollution, resource waste, and inability to realize construction waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

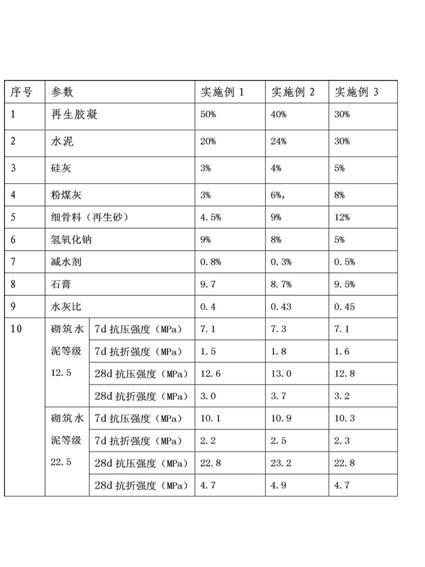

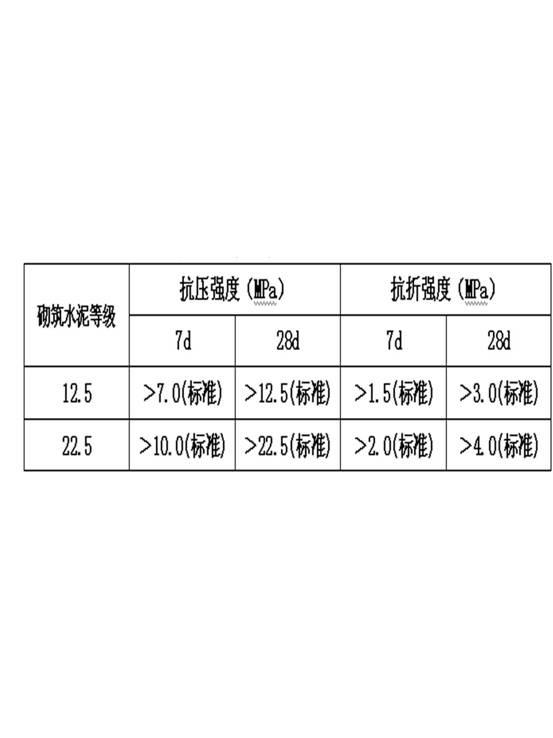

[0017] 1, the preparation method of the cementitious material for construction prepared with construction waste, each embodiment is shown in Table 1, and the concrete steps are as follows:

[0018] 1) Raw materials: pretreatment of construction waste, removal of sundries, retention of waste concrete, waste brick, waste sand ash, waste slag;

[0019] 2) Equipment: Model LGG03-II drum regenerator produced by Huazhong University of Science and Technology; LPM5A-150×2 air shock bag filter produced by Zhejiang Haining Jiehua Group Co., Ltd.;

[0020] 3) Crush and sieve waste concrete, waste brick, waste sand and ash, and waste slag to obtain particles with a particle size of less than or equal to 4.75mm;

[0021] 4) Put the particles obtained in step 3 into the drum regenerator for treatment, and the regeneration treatment makes the construction waste particles rub and collide with each other, remove the inert film on the sand particles, and activate the surface activity of the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com