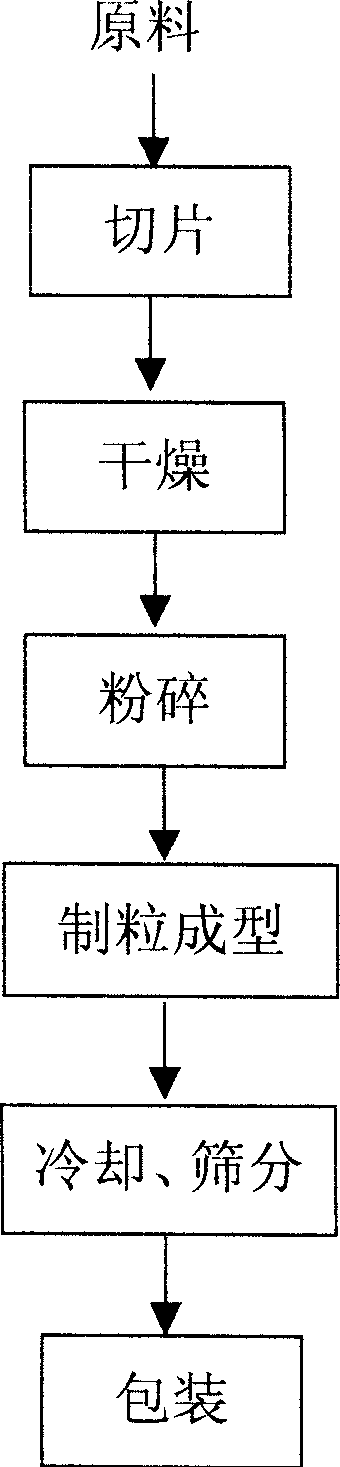

Environment-protecting granular wooden fuel and its production process

A wood pellet and fuel technology, applied in the field of wood pellet fuel and its molding process, can solve the problems of high product cost, expensive, complicated process, etc., and achieve energy saving and boiler equipment investment, product cost reduction, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

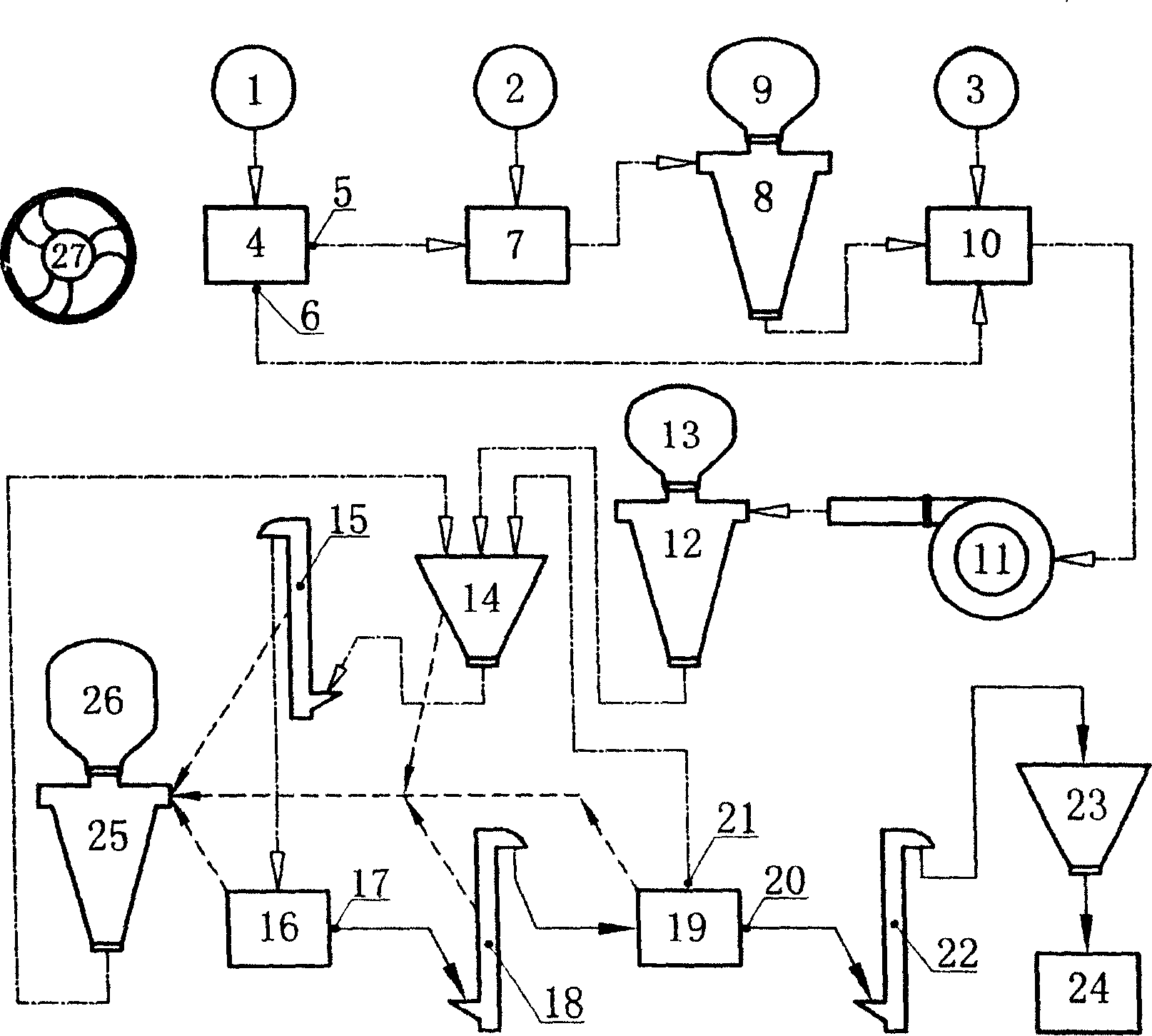

[0031] 1. Equipment installation method

[0032] see figure 2, Slicer 4, Airflow Dryer 7, Coarse Material Cyclone Separator 8, Pulverizer 10, Air Conveyor 11, Powder Material Cyclone Separator 12, Powder Material Storage Hopper 14, Powder Material Elevator 15, Granulator 16, The hot granule elevator 18, the cooling and screening combination machine 19, the cold granule elevator 22, the finished granule storage hopper 23, and the packing machine 24 are connected according to the process sequence, and the coarse material cloth bag 9 is connected to the air outlet of the coarse material cyclone separator 8, and the powder The cloth bag 13 is connected to the air outlet of the powder material cyclone separator 12 . Auxiliary equipment: Ventilation equipment 27 is installed at the vent of the factory building, and the air inlet of the dust removal cyclone separator 25 is connected to the equipment that needs dust removal, such as powder storage hopper 14, powder hoist 15, granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com