Organic material tray type three-dimensional fermentation system and fermentation method thereof

A technology of organic materials and fermentation systems, which is applied in the preparation of organic fertilizers, organic fertilizers, and biological organic part treatment, etc., to reduce maintenance difficulty, inhibit the effect of anaerobic microorganisms, and save land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the tray-type three-dimensional fermentation system for organic materials and its fermentation method for organic materials proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, method, step, feature and effect thereof, detailed description is as follows.

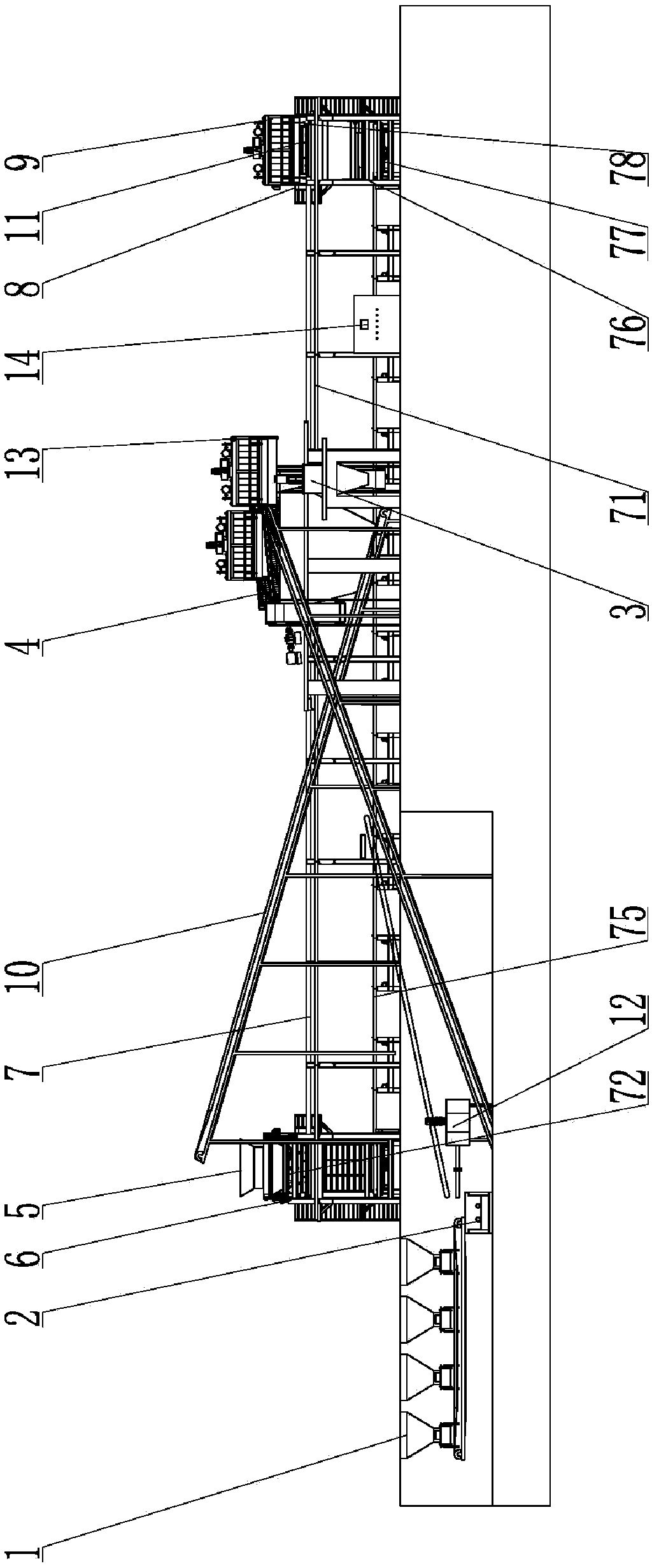

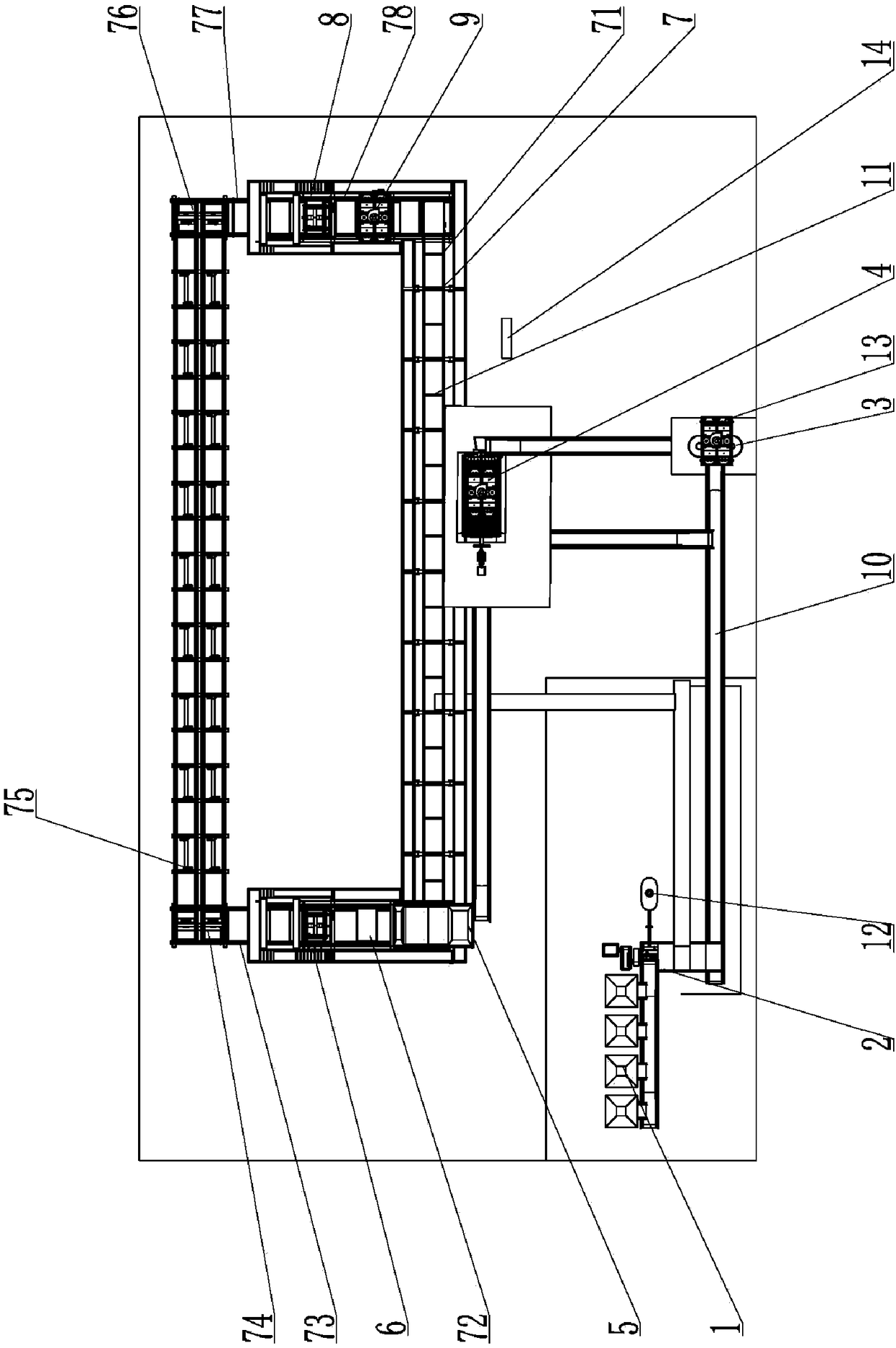

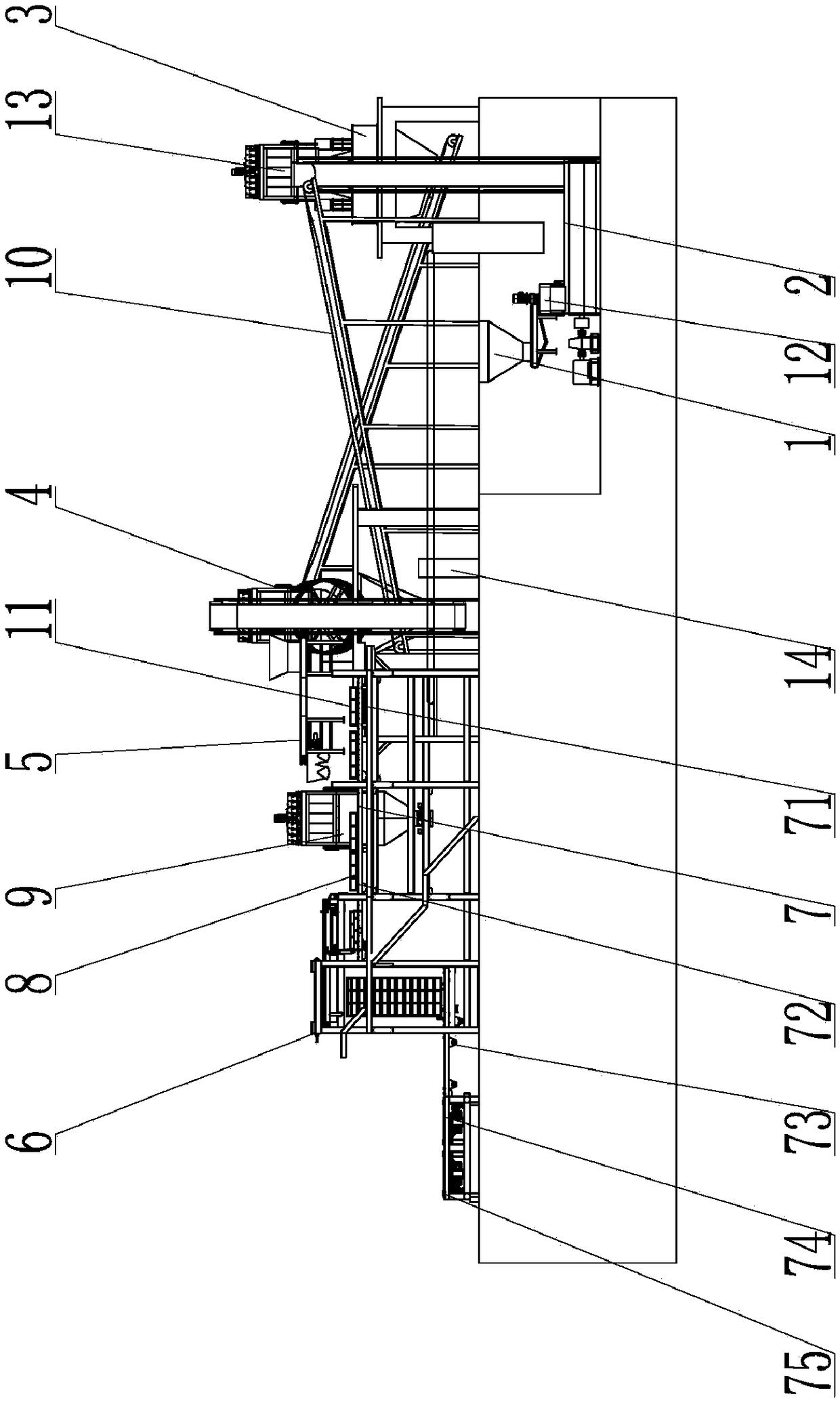

[0051] see Figure 1 to Figure 3 As shown, the organic material tray-type three-dimensional fermentation system of the present invention is mainly composed of a fermentation tray 11, a tray loading device 5, a tray palletizer 6, a tray conveying device 7, a tray depalletizer 8 and a tray dumper 9. The tray loading equipment 5, the pallet stacker 6, the tray depalletizer 8 and the tray turning and unloading machine 9 are installed in sequence, and the tray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com