Dispersion and surface treatment method of nano-sized mineral admixture

A mineral admixture, nano-sized technology, applied in the field of cement concrete admixtures, can solve the problems of poor dispersibility and serious particle agglomeration, and achieve the effect of stable dispersion effect and promotion of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

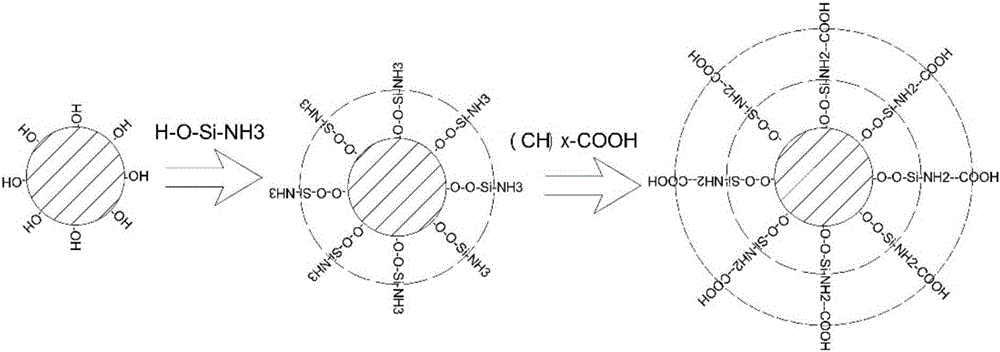

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 15 grams of silica fume powder purchased in the market, add it to 500 milliliters of water, and ultrasonically disperse it for 30 minutes;

[0036] (2) Add 3 grams of γ-aminopropyltriethoxysilane dropwise to the dispersion in step (1), while mechanically stirring for 20 hours at a temperature of 65 degrees Celsius at a stirring rate of 400 rpm ;

[0037] (3) Weighing 15 grams of polyacrylic acid with a molecular weight of 3000, slowly added to the dispersion solution in step (2), while mechanically stirring for 1 hour at a temperature of 65 degrees Celsius at a stirring rate of 400 rpm;

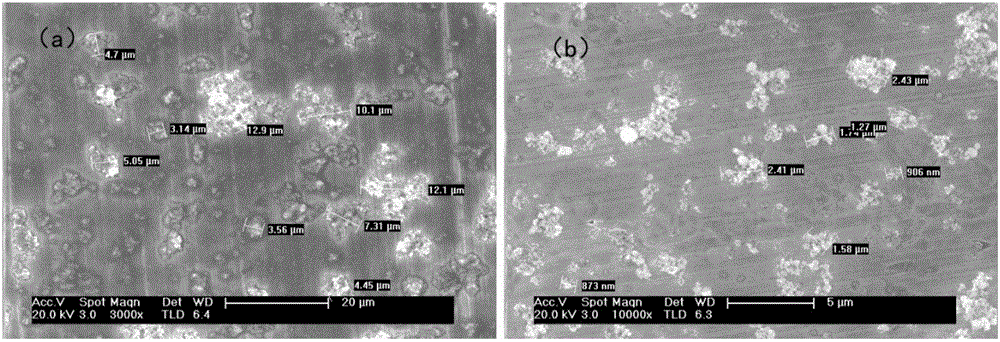

[0038] (4) Suction filter the dispersion solution with filter paper, wash with distilled water and absolute ethanol three times respectively, and dry in a drying oven at 40 degrees Celsius for 24 hours to obtain a surface-treated silica fume powder. figure 2 Among them, (a) is the SEM morphology of the particles before surface treatment, and (b) is the SEM morphology after s...

Embodiment 2

[0040] (1) Take 15 grams of silica fume powder purchased in the market, add to 500 milliliters of water, and mechanically stir for 30 minutes;

[0041] (2) Add 2 grams of γ-aminopropyltrimethoxysilane dropwise to the dispersion in step (1), while mechanically stirring for 16 hours at a temperature of 65 degrees Celsius at a stirring rate of 600 rpm;

[0042] (3) Weigh 9 grams of polymethacrylic acid and slowly add it to the dispersion solution in step (2), while mechanically stirring for 2 hours at a temperature of 65 degrees Celsius at a stirring rate of 600 rpm;

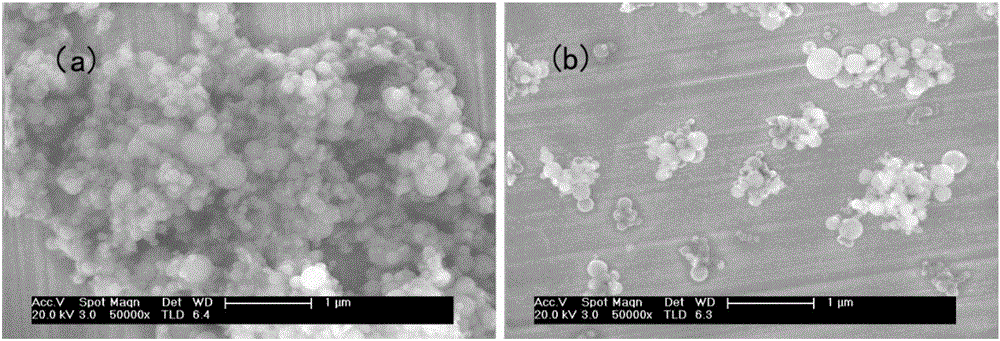

[0043] (4) Suction filter the dispersion solution with filter paper, wash with distilled water and absolute ethanol three times respectively, and dry in a drying oven at 50 degrees Celsius for 24 hours to obtain a surface-treated silica fume powder. image 3 Among them, (a) is the SEM morphology of the particles before surface treatment, and (b) is the SEM morphology after surface treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com