Blending processing method of graphene filled system based on series explosion effect

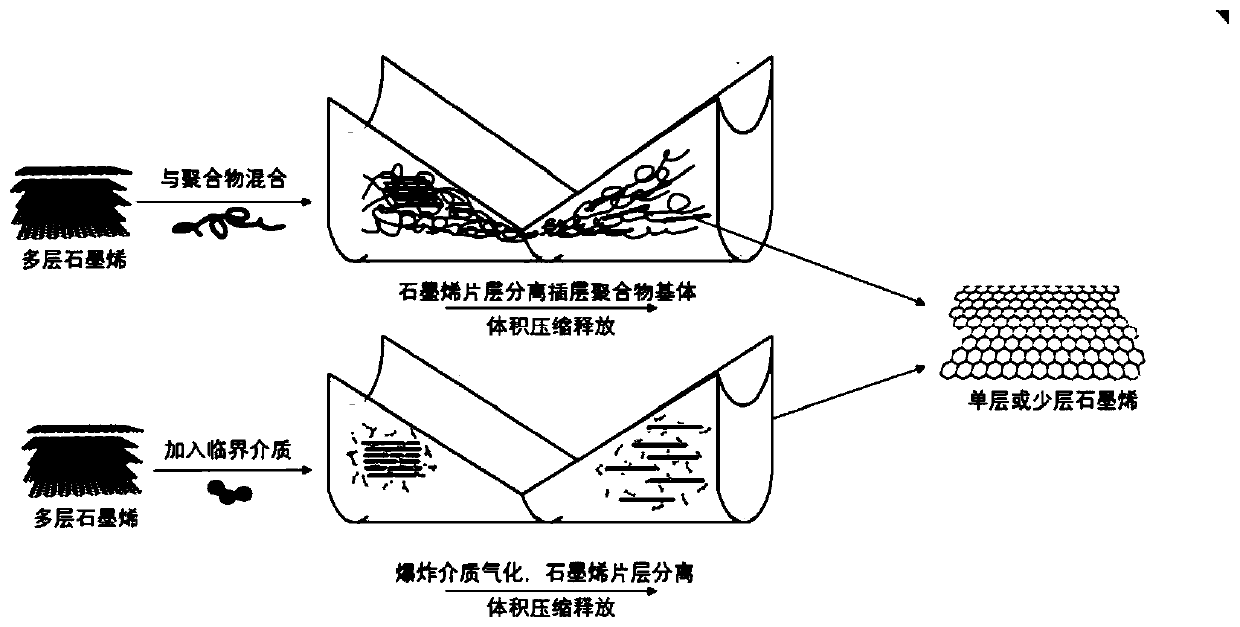

A filling system and processing method technology, applied in the field of polymer material molding and processing, can solve the problems of lack of long-term continuity, easy to destroy graphene sheet structure, difficult to process graphene filling system, etc., and achieve enhanced peeling and dispersion effect. , Wide range of viscosity, the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Graphene filling system, by mass percent, comprises the following components: 94.5wt% (mass fraction) high-density polyethylene (density=0.95g / cm 3 , melt flow rate: 24g / 10min), 5wt% graphene microflakes (thickness 120nm, average sheet diameter 6μm), 0.5wt% (mass fraction) antioxidant 1010.

[0036] A method for blending and processing graphene-filled systems based on series explosion effects, comprising the following steps:

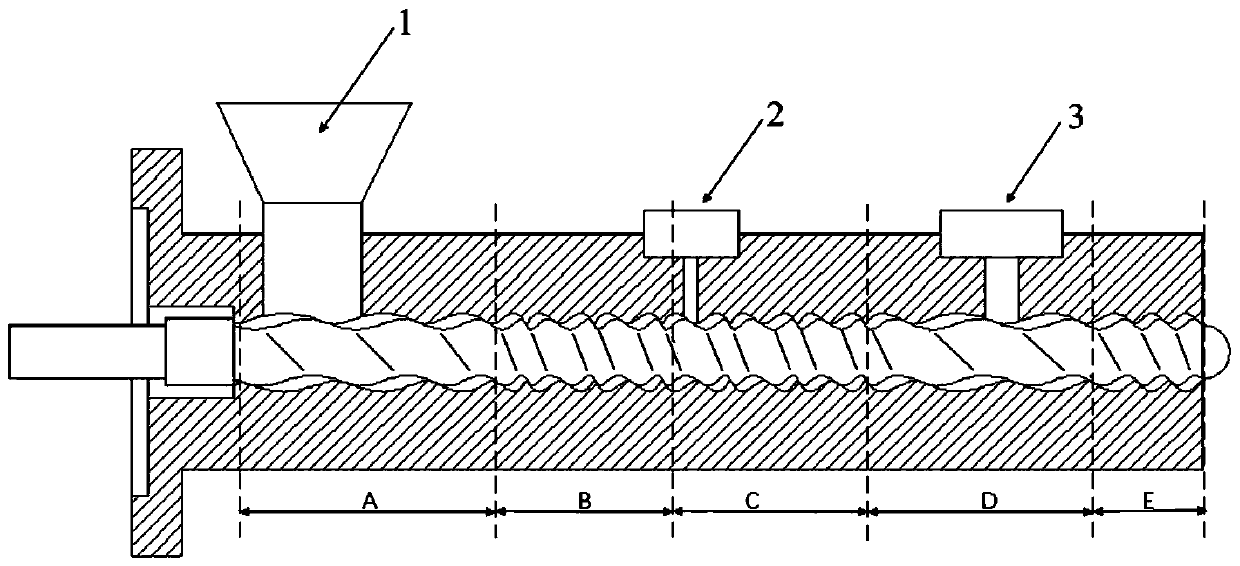

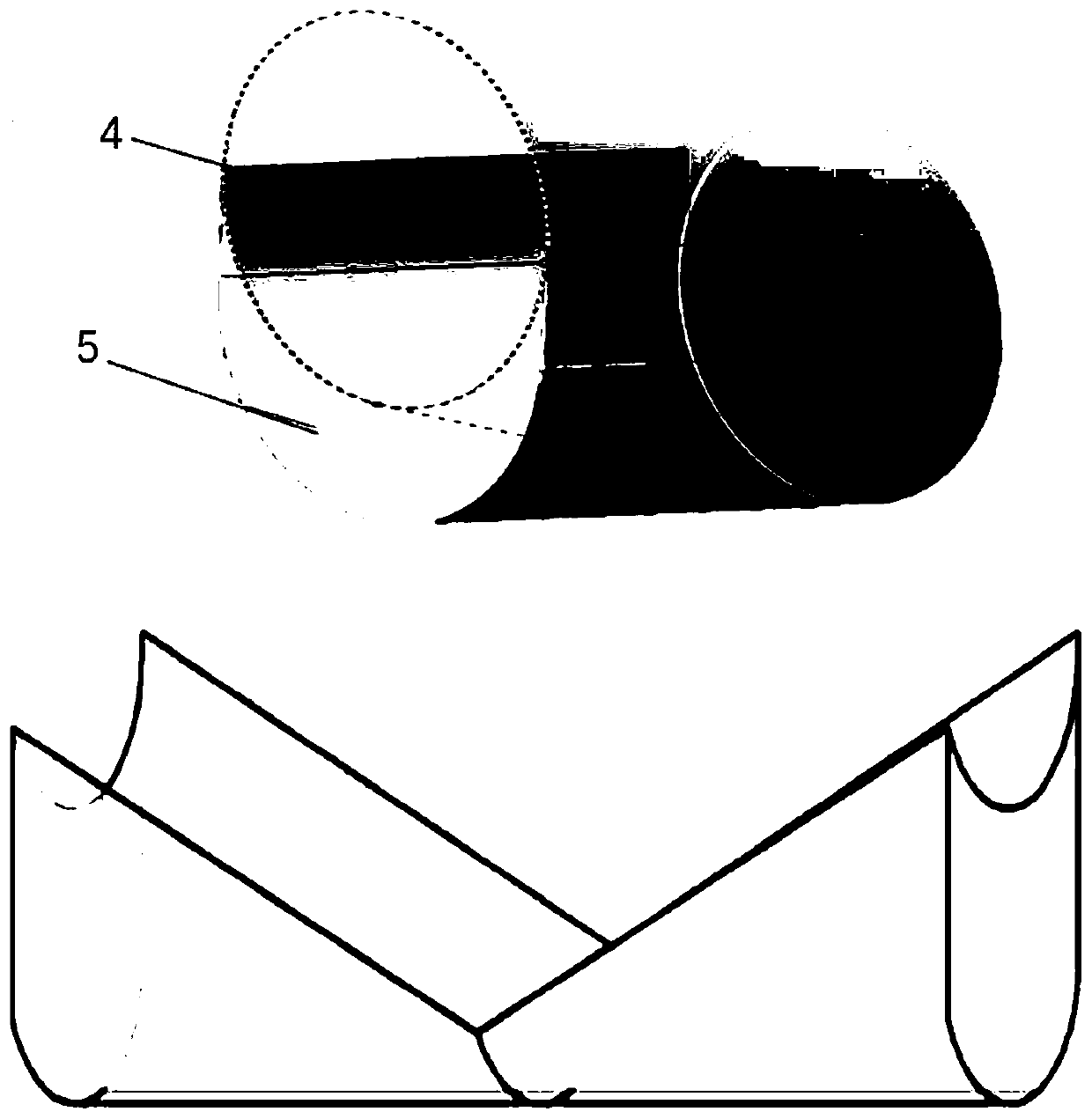

[0037] S1. Add the graphene filling system through the feeder figure 1 The volumetric pulsation plasticization delivery device is shown. In the direction of material conveying, the pitch of the feeding section gradually decreases, the pitch ratio of the head to the tail is 3.5, and the graphene filling system completes the compaction process in the feeding section.

[0038]S2. The screw pitch of the melting and plasticizing section remains unchanged, which is smaller than the pitch at the end of the feeding section. In the melting and plasticiz...

Embodiment 2

[0043] Graphene filling system, by mass percent, comprises the following components: 90wt% (mass fraction) polypropylene (density=0.9g / cm 3 , melt flow rate: 24g / 10min), 10wt% graphene microflakes (thickness 100nm, average sheet diameter 8μm), critical medium is supercritical CO 2 .

[0044] A method for blending and processing graphene-filled systems based on series explosion effects, comprising the following steps:

[0045] S1. Add the graphene filling system through the feeder figure 1 Shown is the volumetric pulsation in the plastified delivery system. In the material conveying direction, the pitch of the feed section decreases gradually, and the pitch ratio of the head to the tail is in the range of 3.0-6.0. The graphene filling system completes the compaction process in the feed section.

[0046] S2. The pitch of the melting and plasticizing section remains unchanged, which is less than or equal to the pitch at the end of the feeding section. In the melting and plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com