Active multifunctional carrier for microorganism self-repairing concrete and preparation method thereof

A multi-functional, microbial technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of insufficient impermeability and recovery of mechanical properties, long-term decline of microbial activity, and poor self-healing effect, so as to improve the self-healing effect and promote The effect of self-healing, enhancing the ability to deposit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

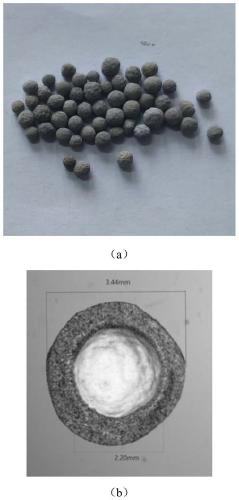

[0036] (1) The internal functional components are based on 100% by mass, consisting of 5% carbonate slow-release components (ie 5wt% sodium carbonate), 60% pozzolanic active components (ie 20wt% fly ash, 20wt% silica fume and 20wt% % metakaolin), 30% inert filler component (ie 30wt% calcium carbonate powder) and 5% microbial powder component (ie 5wt% Bacillus subtilis powder), mix and stir the raw materials according to the above ratio and set aside.

[0037] (2) Add 5g of fly ash beads with a particle size of 0.3-0.5mm in the disc granulator as the granulation core;

[0038] (3) Turn on the water mist humidifier, the flow rate is 25ml / min, and the spraying time is 10s;

[0039] (4) Weigh 100g of pre-mixed raw materials and add them to the disc granulator. After the powder is evenly wrapped on the fly ash sinking beads, turn on the water mist humidifier until the surface of the granules is wet;

[0040] (5) Repeat step (4) until the particle radius reaches the design size;

...

Embodiment 2

[0047] (1) The internal functional components are based on 100% by mass, consisting of 10% carbonate slow-release components (ie 10wt% sodium carbonate), 50% pozzolanic active components (ie 20wt% fly ash, 20wt% silica fume and 10wt% % metakaolin), 38% inert filler component (that is, 38wt% quartz powder) and 2% microbial powder component (Bacillus subtilis powder), mix and stir the raw materials according to the above ratio and set aside.

[0048] (2) Add 5g of fly ash beads with a particle size of 0.3-0.5mm in the disc granulator as the granulation core;

[0049] (3) Turn on the water mist humidifier, the flow rate is 25ml / min, and the spraying time is 10s;

[0050] (4) Weigh 100g of pre-mixed raw materials and add them to the disc granulator. After the powder is evenly wrapped on the fly ash sinking beads, turn on the water mist humidifier until the surface of the granules is wet;

[0051] (5) Repeat step (4) until the particle radius reaches the design size;

[0052] (6) P...

Embodiment 3

[0059] (1) The internal functional components are based on 100% by mass, consisting of 15% carbonate slow-release components (ie 15wt% sodium carbonate), 40% pozzolanic active components (15wt% fly ash, 15wt% silica fume and 10wt% Metakaolin), 40% inert filler component (ie 20wt% calcium carbonate powder and 20wt% quartz powder) and 5% microbial powder component (ie 5wt% alkali-resistant Bacillus powder), mix the raw materials according to the above ratio Stir well and set aside.

[0060] (2) Add 5g of fly ash beads with a particle size of 0.3-0.5mm in the disc granulator as the granulation core;

[0061] (3) Turn on the water mist humidifier, the flow rate is 25ml / min, and the spraying time is 10s;

[0062] (4) Weigh 100g of pre-mixed raw materials and add them to the disc granulator. After the powder is evenly wrapped on the fly ash sinking beads, turn on the water mist humidifier until the surface of the granules is wet;

[0063] (5) Repeat step (4) until the particle rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com