All-solid waste cementing material as well as preparation method and application thereof

A technology of cementitious materials and application methods, applied in the direction of cement production, etc., can solve problems such as increased processing costs, complex raw materials and processes, road collapse, etc., and achieve the effect of increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

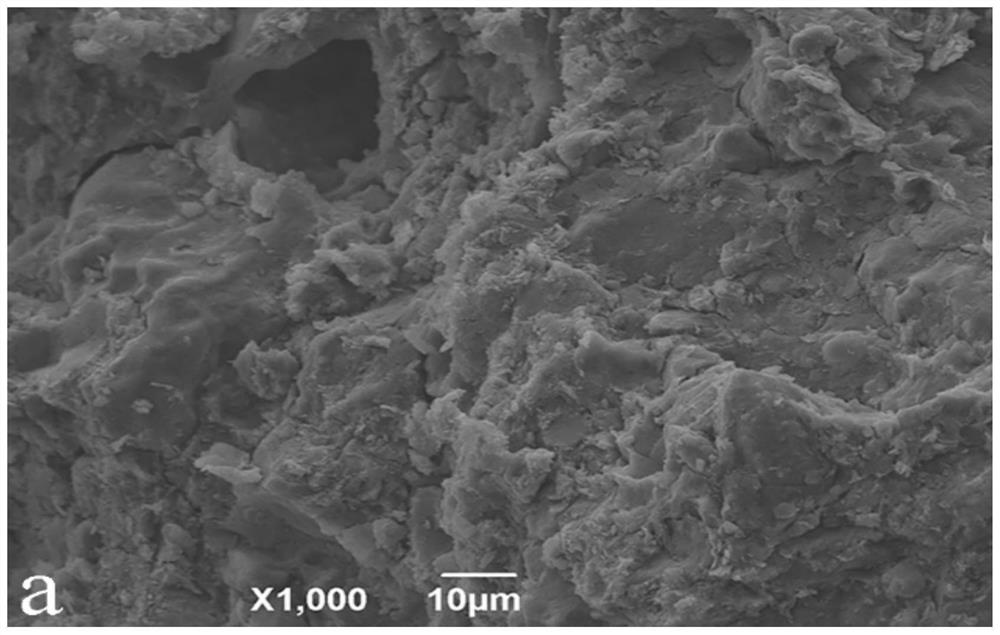

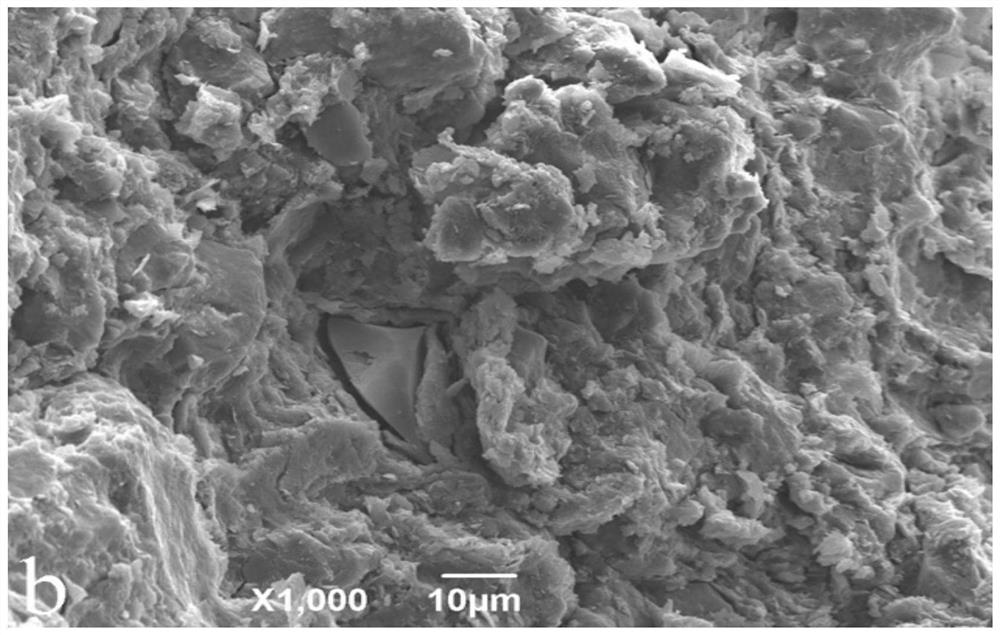

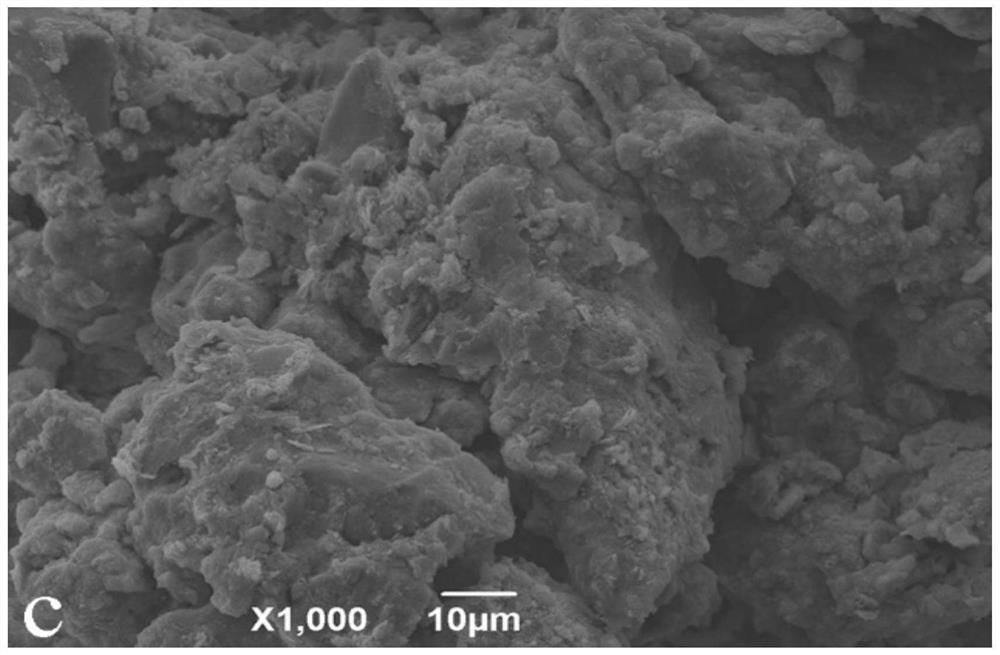

Image

Examples

preparation example Construction

[0036] The invention provides an all-solid waste gelling material as well as a preparation method and application thereof.

[0037] The all-solid cementitious material includes 22.5% to 27.5% phosphogypsum, 22.5% to 27.5% calcium carbide slag, and 45% to 55% slag micropowder in terms of mass percentage, wherein the calcium carbide slag is ground to a particle size ≤ 280 μm and sieved through an 80 μm sieve Balance ≤ 20%, slag fine powder ground to particle size ≤ 212μm, specific surface area > 350m 2 / Kg, the phosphogypsum is ground to a particle size of ≤280 μm, and the sieve residue of 80 μm is ≤20%.

[0038] The preparation method of the all-solid cementitious material is roughly as follows: First, phosphogypsum and calcium carbide slag are mixed by mass percentage for 15 minutes and then calcined. During the calcining process, the heating rate is 5°C / min, and the temperature is raised to 800°C for 120min. The calcined product is ground to a particle size of ≤80 μm; then, ...

Embodiment 1

[0041] This embodiment is a method for preparing all-solid waste cementitious materials, the method comprising the following steps:

[0042] 1) According to mass percentage, 22.5% phosphogypsum and 22.5% calcium carbide slag were stirred and mixed for 15 minutes, and then calcined. During the calcining process, the heating rate was 5°C / min, and the temperature was raised to 800°C for 120min. Calcined to obtain a calcined product, and the calcined product was ground To particle size ≤ 80μm;

[0043] 2) Stir and mix the ground calcined product powder and 55% slag fine powder for 45 minutes.

[0044] A method for applying all-solid waste cementitious materials, the method comprising the steps of:

[0045] S1. Mix the soil to be treated with the all-solid waste roadbed pavement material at a dry weight mass ratio of 9:1, and mix evenly to obtain a mixture;

[0046] S2. Add water to the mixture according to the water-binder ratio of 2:1, stir and mix evenly at room temperature to...

Embodiment 2

[0051] This embodiment is a method for preparing all-solid waste cementitious materials, the method comprising the following steps:

[0052] 1) Mix 25% phosphogypsum and 25% calcium carbide slag by mass percentage for 15 minutes and then calcined. During the calcining process, the heating rate is 5°C / min, and the temperature is raised to 800°C for 120 minutes. Calcined to obtain a calcined product, and the calcined product is ground To particle size ≤ 80μm;

[0053] 2) Stir and mix the ground calcined product powder and 50% slag fine powder for 45 minutes.

[0054] A method for applying all-solid waste cementitious materials, the method comprising the steps of:

[0055] S1. Mix the soil to be treated with the all-solid waste roadbed pavement material at a dry weight mass ratio of 9:1, and mix evenly to obtain a mixture;

[0056] S2. Add water to the mixture according to the water-binder ratio of 2:1, stir and mix evenly at room temperature to form a glue mixture with uniform p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com