Cement-based porous material based on silicon dioxide and preparation method of cement-based porous material based on silicon dioxide

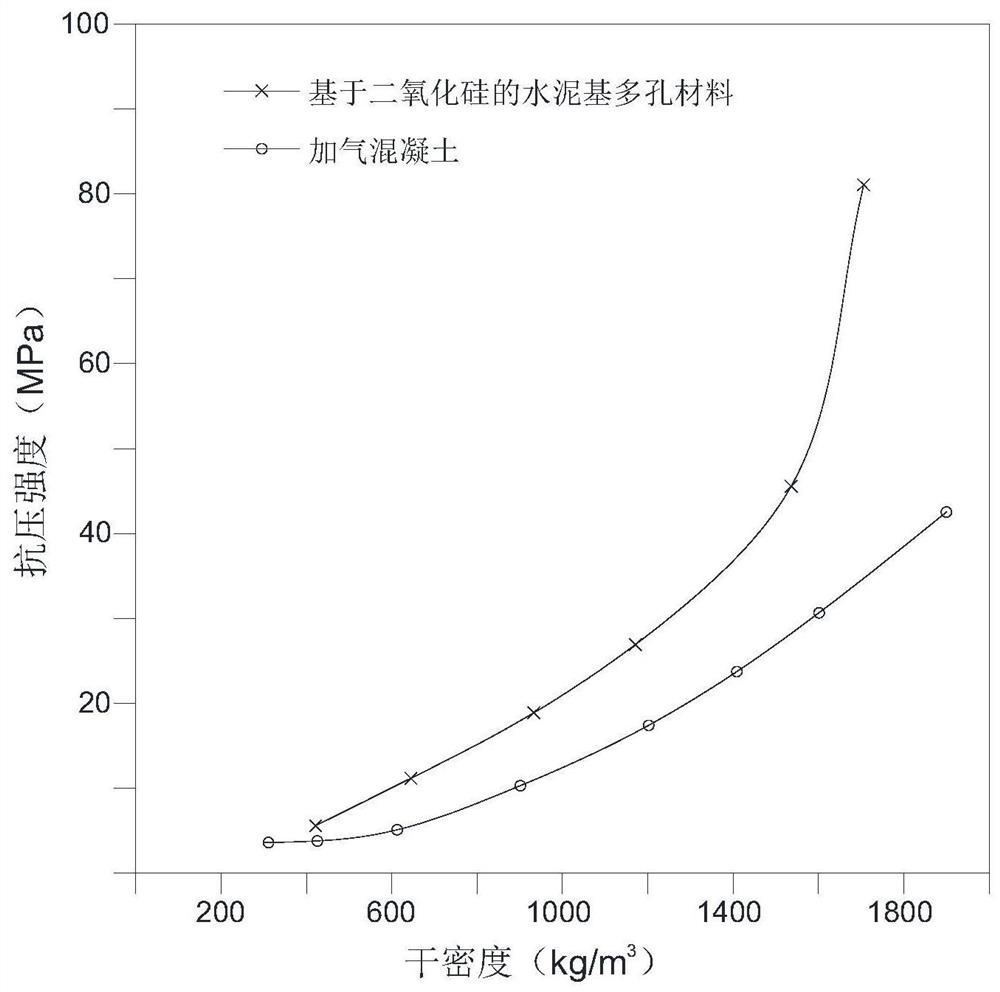

A technology of silica and porous materials, applied in the field of building materials, can solve the problems of reduced mechanical properties of porous materials, weakening of mechanical properties of cement-based porous materials, etc., to increase the proportion of nanopores, which is conducive to the improvement of material strength and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A cement-based porous material based on silica. The cement-based porous material is mainly a porous material obtained by mixing cement, admixture, water, admixture and silica dispersion liquid and then coagulating and hardening; wherein the water-cement ratio is 0.2-2, the amount of admixture is 0-30% of the mass of cement and admixture; the silica dispersion is a dispersion system formed by dispersing silica particles in water.

[0022] The specific operation steps of the preparation method of the silica-based cement-based porous material in this embodiment are as follows:

[0023] S1. Add silicon dioxide powder to water, use any one or more of mechanical stirring, ultrasonic dispersion, adding water reducing agent or adding surfactant to disperse silicon dioxide in water to form silicon dioxide Dispersions;

[0024] S2. Weigh cement, admixture, water, and admixture according to the ratio and stir them evenly to obtain a base material; Additive for cement and concret...

Embodiment 2

[0031] In this embodiment, the water-to-binder ratio is selected as 0.3, and the matrix material is prepared by stirring P.O 42.5 cement, water, and admixture (solid content 10%); the silicon dioxide powder is pre-dispersed in water for 5-60 minutes by ultrasonic waves to obtain a solid content of 30%. % silica dispersion liquid; then use the volume substitution method to design and calculate the mixed dosage of matrix material and silica dispersion liquid under different dry densities, and the proportioning ratio is shown in the following table 1:

[0032] Table 1 Mixing ratio of silica-based cement-based porous materials (kg / m 3 )

[0033] Numbering Design Dry Density cement water Admixture Silica Dispersion 1 1800 2000 585.6 16.00 0 2 1500 1100 322.1 8.80 295 3 1200 840 246.0 6.72 548 4 900 600 175.7 4.80 845 5 600 280 82.0 2.24 1151 6 400 90 26.4 0.72 1372

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com