Coal ash activity exciting agent and preparing method of coal ash activity exciting agent

An active activator, fly ash technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high cost, affecting the quality of concrete and other materials, corrosion of steel bars by chloride salts, etc. Unsaturated bonds, the effect of promoting pozzolanic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

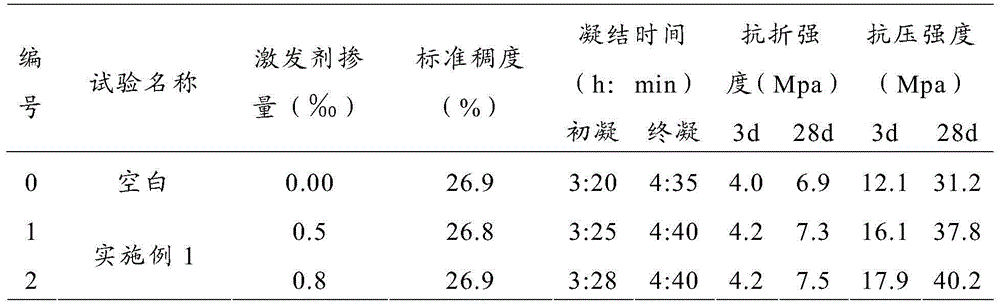

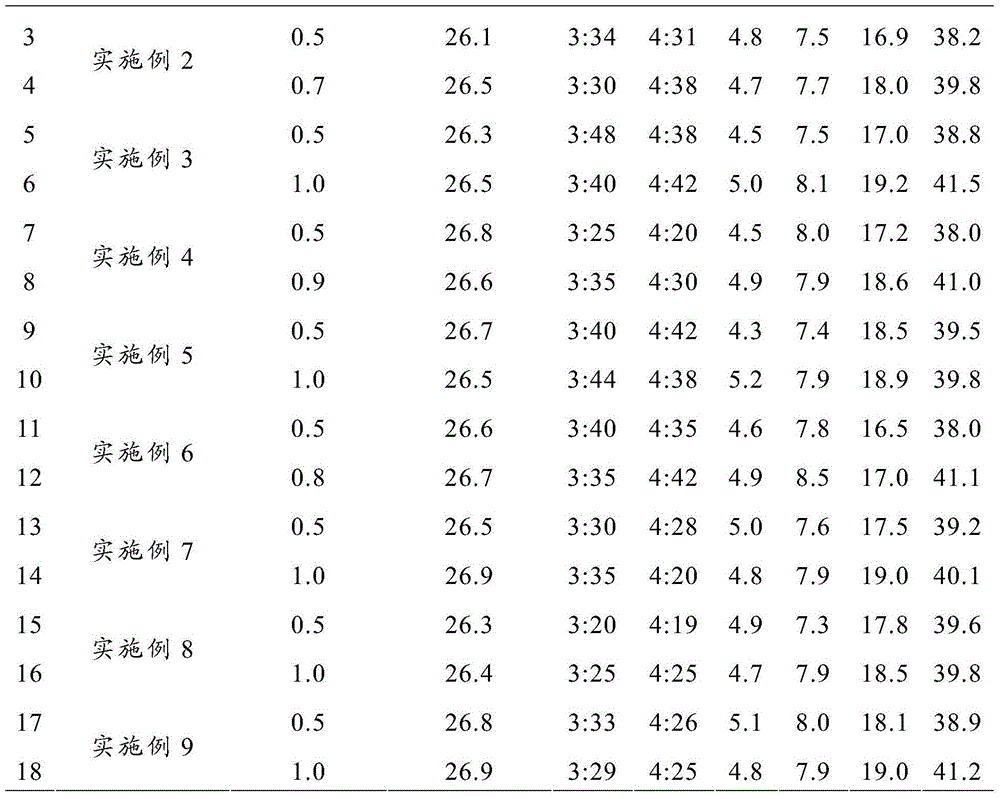

Examples

preparation example Construction

[0034] Correspondingly, the present invention provides a kind of preparation method of above-mentioned fly ash activity stimulating agent, comprises the following steps:

[0035] Sodium p-aminobenzenesulfonate, water, lye, acetone, urea and formaldehyde solution are mixed and then reacted to obtain a fly ash active activator.

[0036] The invention provides a preparation technology of a fly ash activity activator. The prepared activator has high activation activity and low dosage, can not only effectively stimulate the activity of fly ash, but also improve the performance of concrete and the like. Moreover, the activator is a synthetic polymer product with uniform and stable quality.

[0037] In the embodiment of the present invention, add sodium p-aminobenzenesulfonate, water, lye, acetone, urea and formaldehyde solution into a reaction kettle, and react after mixing to obtain a fly ash activity activator.

[0038] Preferably, the preparation method specifically includes the...

Embodiment 1

[0061] Get 30g of sodium sulfanilate and 80g of water into the reaction flask, start stirring, after the sodium sulfanil is completely dissolved, add a sodium hydroxide solution with a mass concentration of 30%, adjust the pH value to 12, and obtain a mixed solution; the mixed solution was warmed up to 50°C, 20g of acetone and 10g of urea were added thereto, continued to stir, and reacted at a constant temperature for 0.5h to obtain a reaction solution; the reaction solution was warmed up to 75°C, and 80g of mass was added dropwise The formaldehyde solution with a concentration of 37% was added dropwise within 2 hours by controlling the rate of addition; finally, the temperature was raised to 90°C, and the reaction was continued for 3 hours, and the temperature was lowered to discharge the material to obtain a brownish-red transparent liquid product, that is, the fly ash active activator.

[0062] The number-average molecular weight of the fly ash activator is 5000, the viscosi...

Embodiment 2

[0069] Get 40g of sodium sulfanilate and 90g of water into the reaction flask, start stirring, and after the sodium sulfanil is completely dissolved, add a sodium hydroxide solution with a mass concentration of 30%, adjust the pH value to 12, and obtain a mixed solution; the mixed solution was heated up to 50°C, 25g of acetone and 10g of urea were added thereto, continued to stir, and reacted at a constant temperature for 1.0h to obtain a reaction solution; the reaction solution was raised to 75°C, and 90g of mass was started to be added dropwise The formaldehyde solution with a concentration of 37% was added dropwise within 2 hours by controlling the rate of addition; finally, the temperature was raised to 90°C, and the reaction was continued for 3 hours, and the temperature was lowered to discharge the material to obtain a brownish-red transparent liquid product, that is, the fly ash active activator.

[0070] The number average molecular weight of the fly ash activator is 76...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com