Salt-tolerant water-retaining agent containing minerals and preparation method thereof

A water-retaining agent and mineral technology, applied in fertilizer mixture, alkaline orthophosphate fertilizer, ammonium orthophosphate fertilizer, etc., can solve the problems of slow efficiency, unscientific original soil greening method, etc., and achieve the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

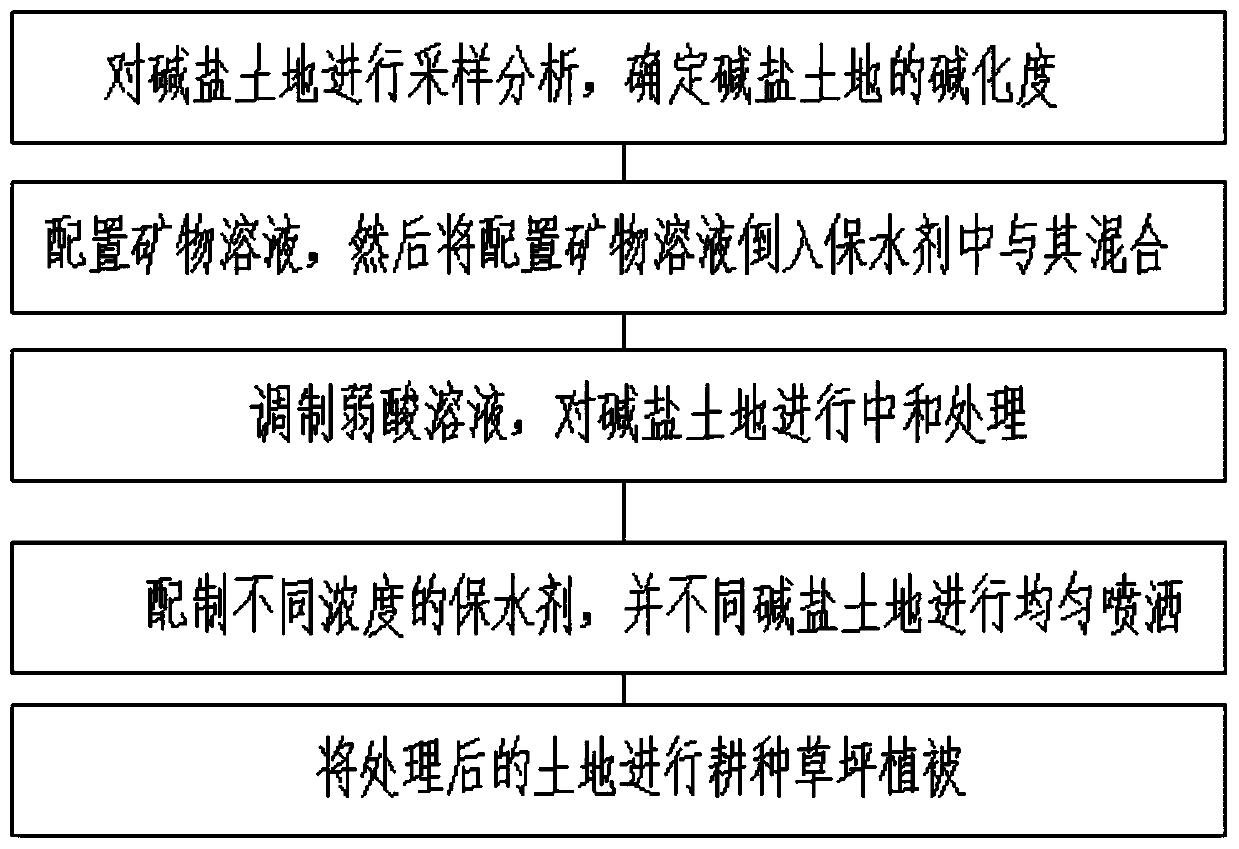

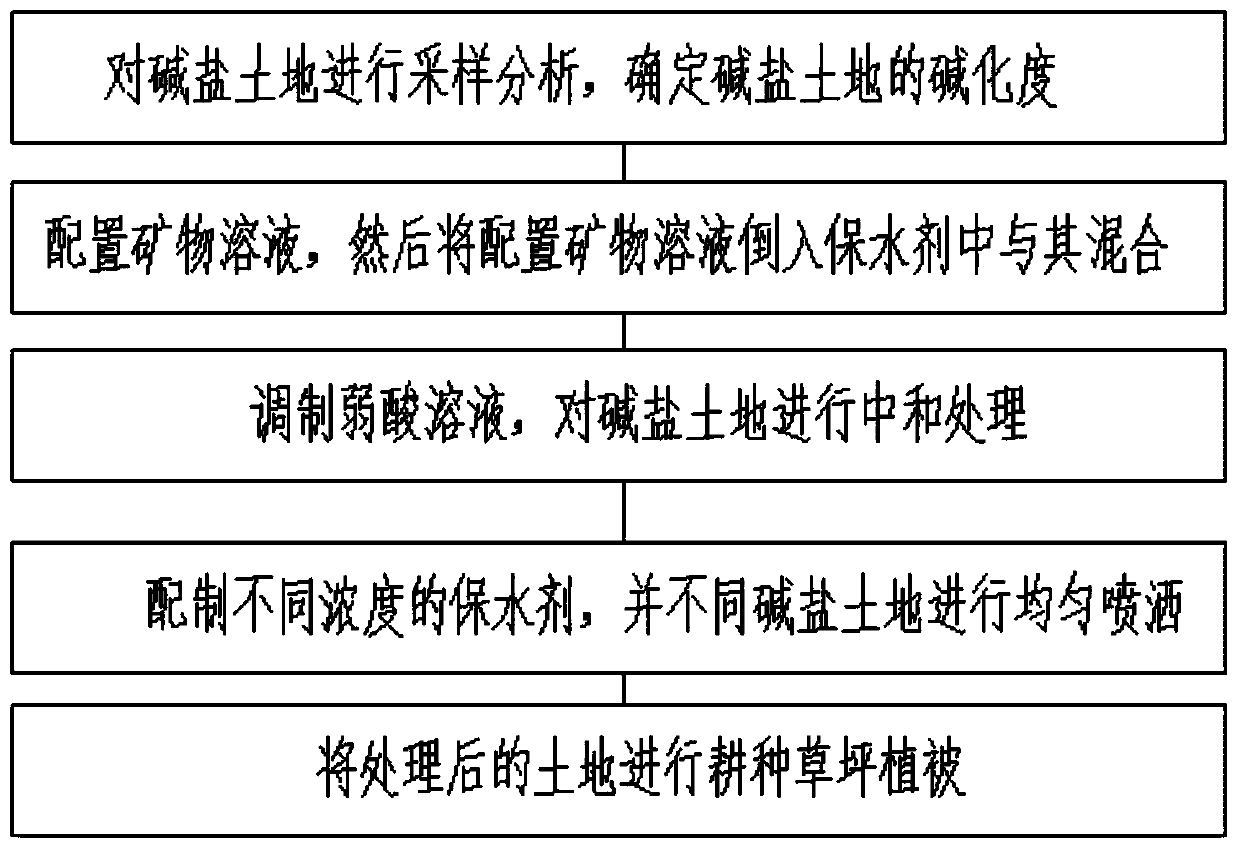

Method used

Image

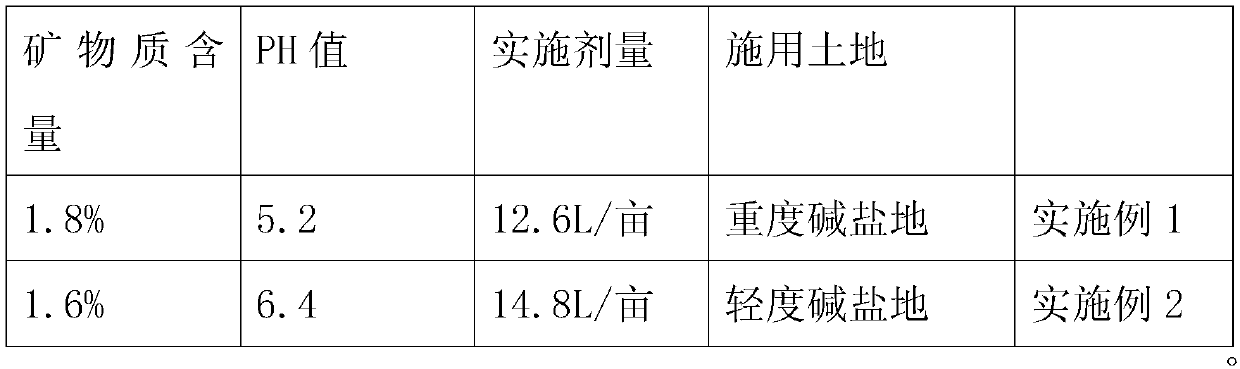

Examples

Embodiment 1

[0036] 2-4g polyacrylamide, 3-8g sodium polyacrylate, 4-7g potassium polyacrylate, 3.5-6g ammonium polyacrylate, 3-8g volcanic ash, 3-10g clay, 2-6 limestone, 1.5-6g rare earth, plant straw 4-8g, sawdust 6-12g, lignin 1.2-1.5g, resin glue 1-4g, urea 1.2-4.3g, manganese sulfate 0.8-1.8g, potassium dihydrogen phosphate 0.6-1.5g, iron sulfate 1.7-3g, Zinc sulfate 1.1-3g.

[0037] Prepare the materials first, and take the above-mentioned raw materials according to the weight in grams;

[0038] Then dry and crush raw materials such as volcanic ash, clay, limestone, and rare earth. First, dry them, then classify the raw materials and send them to the pulverizer in batches, and use a 150-250 mesh screen for crushing;

[0039] Then configure ethanol with a concentration of 80%-90% as a solvent, pour it into and mix it with polyacrylamide, sodium polyacrylate, potassium polyacrylate, and ammonium polyacrylate, and then mix and stir after fully soaking for 1 hour to 2 hours. Control t...

Embodiment 2

[0044]The weight ratio of the ingredients of the water retaining agent includes: 2g of polyacrylamide, 3g of sodium polyacrylate, 4g of potassium polyacrylate, 3.5g of ammonium polyacrylate, 3g of volcanic ash, 3g of clay, 2g of limestone, 1.5g of rare earth, 4g of plant straw, Wood chips 6g, lignin 1.2g, resin glue 1g, urea 1.2g, manganese sulfate 0.8g, potassium dihydrogen phosphate 0.6g, iron sulfate 1.7g, zinc sulfate 1.1g.

[0045] Prepare the materials first, and weigh the above-mentioned raw materials according to the parts by weight;

[0046] Then dry and crush raw materials such as volcanic ash, clay, limestone, and rare earth. First, dry them, then classify the raw materials and send them to the pulverizer in batches, and use a 150-250 mesh screen for crushing;

[0047] Then configure ethanol with a concentration of 80%-90% as a solvent, pour it into and mix it with polyacrylamide, sodium polyacrylate, potassium polyacrylate, and ammonium polyacrylate, and then mix a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com