Compound protein milk beverage and preparation method thereof

A technology for compounding protein and milk beverages, applied in dairy products, milk substitutes, applications, etc., can solve problems such as taste affecting drinking, loss of nutrients, pollution of peanut residues, etc., to shorten production time, improve stability, and reduce waste. and the effects of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

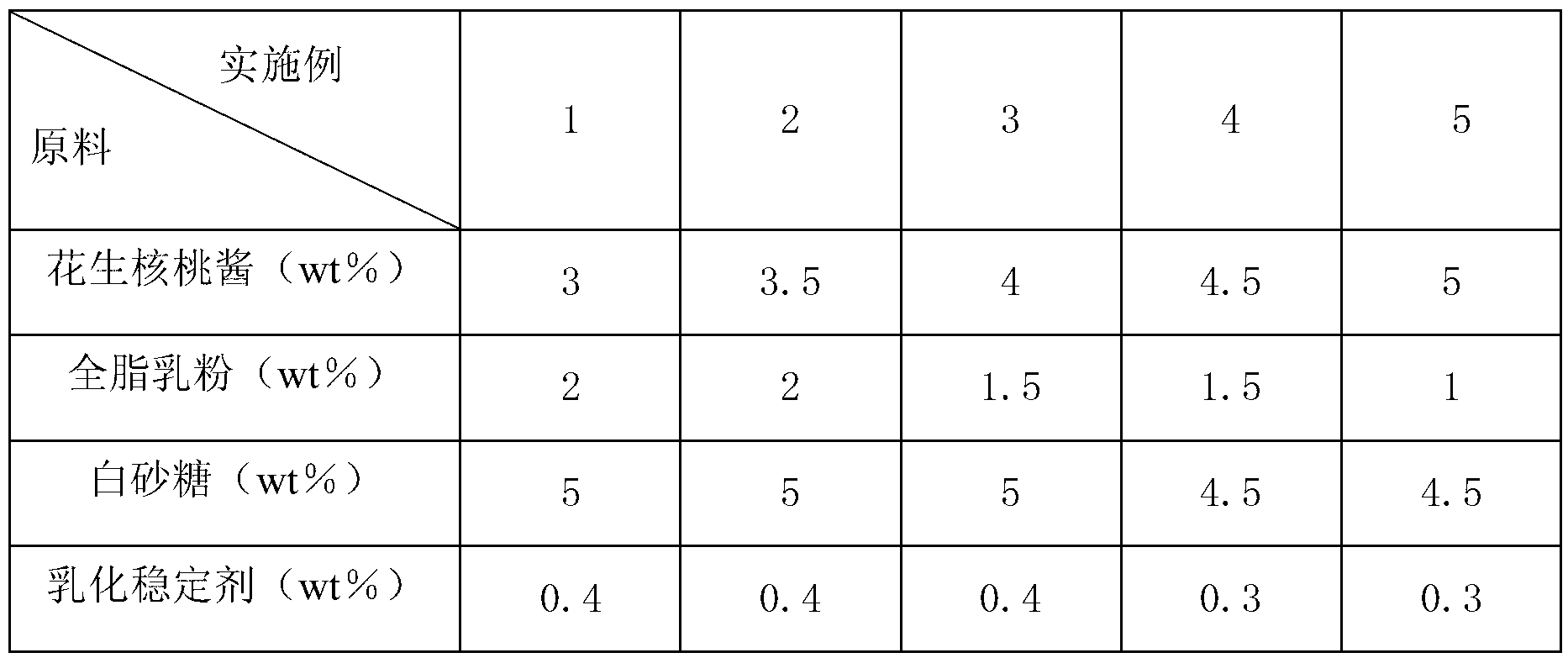

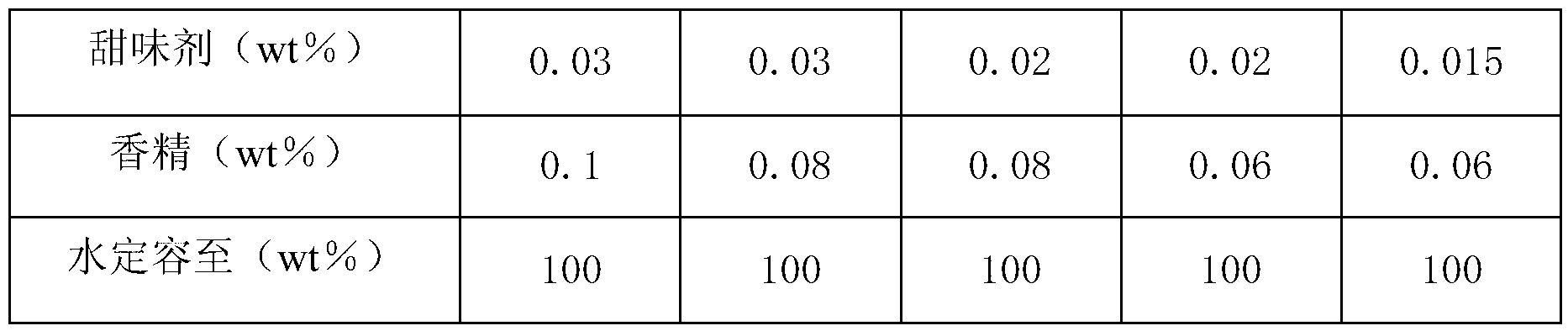

[0040] The composition of the compound protein milk drink of this embodiment is shown in Table 1.

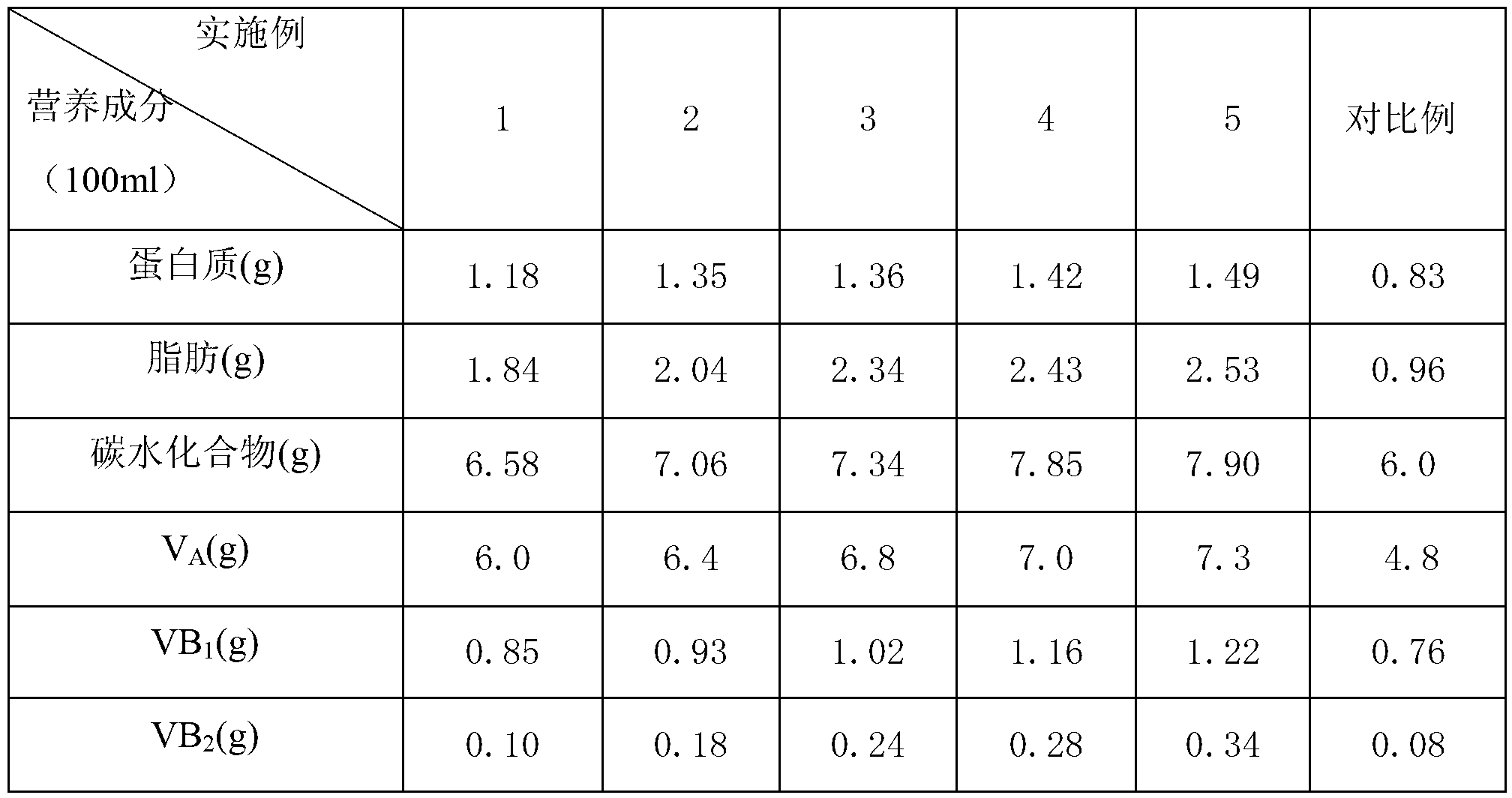

[0041] A method for preparing the above-mentioned compound protein milk drink, the effect is as shown in table 3, and the steps include:

[0042] A. Peanut baking:

[0043] The raw peanut kernels are roasted and peeled on a continuous roaster at 140°C for 1 hour to obtain roasted peanuts with strong aroma;

[0044] B. Grinding roasted peanuts and walnuts:

[0045] The roasted peanuts obtained in step A and the commercially available cooked walnuts are ground to a fineness of 60 μm by a micro-mill and a stone roller mill to a fineness of 30 μm to obtain a fine and rich peanut-walnut sauce;

[0046] C. Ingredients:

[0047] Filter the peanut and walnut butter obtained in step B through a 200-mesh vibrating sieve, add water, whole milk powder, white sugar, emulsification stabilizer, sweetener, essence in proportion, control the temperature at 80°C, and stir for 10 minutes;

[0...

Embodiment 2

[0057] The composition of the compound protein milk drink of this embodiment is shown in Table 1.

[0058] A method for preparing the above-mentioned compound protein milk drink, the effect is as shown in table 3, and the steps include:

[0059] A. Roasting of peanuts:

[0060] Roast raw peanut kernels at 150°C for 0.3h and peel off the skin to obtain roasted peanuts with rich aroma;

[0061] B. Grinding roasted peanuts and cooked walnuts:

[0062] The roasted peanuts and commercially available cooked walnuts obtained in step A are subjected to ultrafine grinding to a fineness of 70 μm and stone roller mills to a grinding fineness of 40 μm to obtain peanut and walnut butter;

[0063] C. Ingredients:

[0064] Filter the peanut and walnut butter obtained in step B through a 300-mesh vibrating sieve, add water, whole milk powder, white sugar, emulsification stabilizer, sweetener, essence in proportion, control the temperature at 70°C, and stir for 20 minutes;

[0065] Describ...

Embodiment 3

[0074] The composition of the compound protein milk drink of this embodiment is shown in Table 1.

[0075] A method for preparing the above-mentioned compound protein milk drink, the effect is as shown in table 3, and the steps include:

[0076] A. Peanut baking:

[0077] Roast raw peanut kernels at 150°C for 0.2h and peel off the skin to obtain roasted peanuts with rich aroma;

[0078] B. Grinding roasted peanut kernels and cooked walnut kernels:

[0079] The roasted peanuts and commercially available cooked walnuts obtained in step A are subjected to ultrafine grinding to a fineness of 80 μm and stone roller mills to a grinding fineness of 30 μm to obtain peanut and walnut butter;

[0080] C. Ingredients:

[0081] Filter the peanut and walnut butter obtained in step B through a 200-mesh vibrating sieve, add water, whole milk powder, white sugar, emulsification stabilizer, sweetener, essence in proportion, control the temperature at 80°C, and stir for 10 minutes;

[0082]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com